In this blog post, we will discuss about early age cracking in concrete and its causes.

Lets get started!

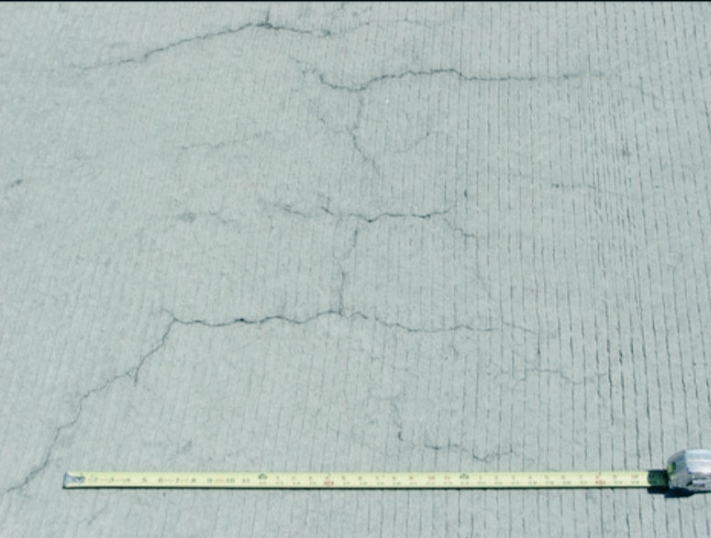

Initial cracking is observed in the first 7 days after concrete placement. However, it can take him a week or more for such cracks to appear in reinforced concrete slabs. Therefore, cracks occurring within he 60 days of concrete placement are considered incipient cracks.

Incipient cracking of concrete does not lead to structural failure unless structural tolerances are exceeded. However, it can lead to premature corrosion of rebar and spalling of concrete pavement, resulting in increased maintenance costs and potentially reduced service life.

Freshly poured concrete can develop premature cracking depending on the composition of the concrete mixture, the exposure environment, the rate of hydration, and the state of hardening. Therefore, it is essential to understand the exact causes in order to consider appropriate measures to prevent premature cracking of concrete.

Table of Contents

Various Causes of Early Age Cracking in Concrete

1. Drying Shrinkage

Drying shrinkage can cause premature cracking if shrinkage is inhibited internally, externally, or a combination thereof. Drying shrinkage is unevenly distributed across the thickness of the concrete component, leading to differential shrinkage. Differential shrinkage causes axial motion and strain. Both of these movements generate axial and bending stresses when the concrete is constrained, leading to premature cracking. Drying shrinkage also creates residual stresses in small elements.

2. Concrete Creep

Concrete creep is another cause of early cracking in concrete. When concrete experiences time-dependent movements due to the application of internal or external stresses, aggregates within concrete restrain these movements. In this case, the concrete may crack.

3. External Loading

Beyond the tensile strength of concrete, external stresses such as vibration, traffic and wind can stress concrete and induce premature age-related cracks.

The tensile strength of concrete when young is rather low and can easily be exceeded. Therefore, the influence of external loads after concrete placement should not be neglected.

4. Plastic Settlement

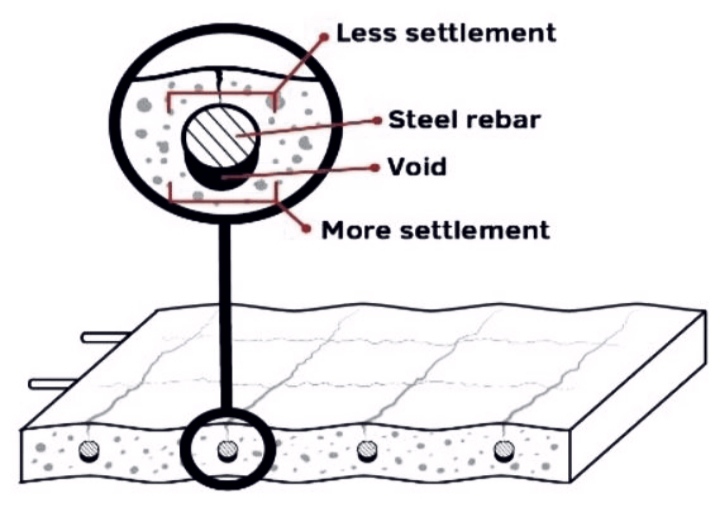

Plastic subsidence is a common factor leading to premature cracking. It occurs when solid particles in a concrete mixture settle due to gravity, causing water to escape and move upwards.

Downward motion of solid particles creates stress when concrete is locally prevented from settling. Therefore, when this stress exceeds the tensile strength of freshly poured concrete, premature age cracking occurs.

Cracking occurs at the constraining source of concrete. Premature cracking due to plastic settlement is common in formwork where the concrete thickness changes rapidly. This is because the deeper the surface, the greater the subsidence, and cracks occur near the change point of the formwork.

5. Autogenous Shrinkage

Autogenous shrinkage can generate large tensile stresses in early concrete, especially high early strength concrete. Autogenous contraction occurs after the driving force is generated by chemical contraction. Chemical shrinkage occurs when the volume of the hydration product becomes smaller than the original volume of the reaction components, cement and water.

The final chemical shrinkage of a typical hydrated Portland cement paste can be as high as 10% by volume. If additional water is not available for hardening after the cement hardens, chemical shrinkage forms empty capillary pores within the hydrated cement paste, known as self-drying. The remaining partially filled pore meniscus generates self-stress that causes self-shrinkage, leading to incipient cracking. Cracks commonly occur around internal restraints such as rebar and aggregates, or through the depth of concrete members when suitable external restraints are present.

6.Temperature Gradient

Temperature gradients occur when concrete is exposed to high temperatures that it cannot dissipate. Thermal stresses occur when there is a large temperature gradient between the inner and outer surfaces of a concrete part.

When concrete members are constrained, thermal stresses easily exceed the concrete’s tensile strength in the early stages of concrete, causing cracking. Constraints in

concrete may result from changes in section depth. Connections between the web and flanges of T-beams or coffer slabs, top stiffeners of beams or slabs, stirrups of columns, formwork sleepers and bridges of coarse aggregate between profiles and bottlenecks.

7. Internal Concrete Temperature

Hydration of cement generates heat of hydration, which can lead to premature cracking. When the internal temperature reaches around 50°C, ettringite becomes unstable and may melt. As the internal temperature drops, ettringite expands, which can lead to internal and external cracking.