In this article, we will discuss about various types of wood veneer. Wood veneer is an important building material. Its popularity is increasing day by day.

Table of Contents

Types of Wood Veneer

I have listed diffrent types of wood veneer. This list is based on veneer cut.

- Natural Wood Veneer

- Decorative Wood Veneer

- Rotary Cut Wood Veneer

- Sliced Wood veneer

- Shop Sawn Wood Veneer

- Rolled Wood Veneer

- Fine Line Wood Veneer

- Multi Layer Wood Veneer

- 3D Wood Veneer

- Spliced Wood Veneer

We will learn about these 10 types of wood veneer.

Let’s get started!

1. Natural Wood Veneer

Natural veneer is a thin sheet that can be sawed, peeled, edged or planed from solid wood. The wood’s characteristic texture is perfectly preserved throughout the manufacturing process. This type of veneer is called natural veneer.

This material is available in the market at very moderate cost. Natural veneer is cheaper than real solid wood. Natural wood gives the furniture a unique pattern. Natural wood is the natural texture of furniture and gives it a timeless look. One of the most commonly used wood veneer types is natural veneer. Natural veneer is often used in the manufacture of modern furniture.

2. Decorative Wood Veneer

Wood comes in a wide variety of natural textures and tones. There are not many ways to decorate it. By using design veneers, you can expand the possibilities and versatility.

Natural wood is used to make carvings and decorative veneers. It is then painted in different tones. This wood veneer retains all the essential wood qualities. This type of veneer allows you to create furniture sets of any color scheme. This wood uses a single texture. You can also combine different shades in the same pattern.

3. Fine Line Wood Veneer

This type of veneer is made by gluing sheets of veneer together and molding them into blocks.The fine line veneer can be reproduced from a rotary cut of softwood veneer. Veneers can be made in a variety of shapes, colors and textures. Fine line veneers have a uniform color tone. This type of veneer can imitate the structure of any type of wood. No knots, voids, or other normal assembly errors.

Mold the peeled softwood veneer into a block to create a fine line veneer. It can be made in various colors, patterns and sizes. These are typically 60 cm leaf sheets.

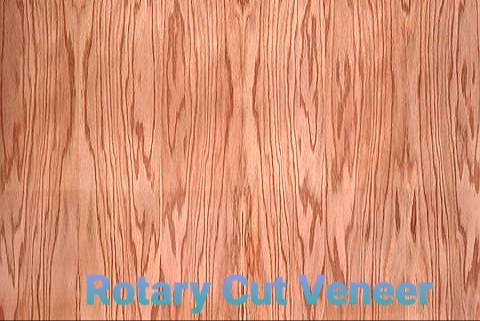

4. Rotary Cut Wood Veneer

Rotary cut veneer is the most common type of veneer used in the buildings. This wood veneer consists of oak, pine, birch and alder. Made with thin “Lust” technology. Remove the bulbous part of the stem. This wood veneer is inexpensive.

A type of projecting board called “rotational cut”. Created by mechanically removing a thin layer of wood from a huge rotating log. Special woodworking machines are used for this. After cutting, the veneer is divided into sheets of a certain size. Each sheet has multiple layers of adhesive.

This is one of the cheapest types of veneer. It does not necessarily match the grain structure and pattern perfectly.

5. Sliced Wood Veneer

Sliced veneer contrasts with stripped veneer. It has a unique texture. This type of veneer is created by varying the cutting angle. Useful for creating strong wood grain patterns. Sliced veneers are produced on a veneer peeler.

The thickness is about 0.2 to 5 mm. Such veneers are mainly made from expensive types of wood with a beautiful texture. As a result, sheets of veneer with a thickness of 0.2 to 3 mm are produced and folded into bundles. In the furniture industry, sliced veneers are commonly used in thicknesses of 0.6, 1.5, 3 mm and 4 mm.

6. Shop Sawn Wood Veneer

This is type of veneer carefully finished by woodworkers. This veneer was sometimes thicker than the adjacent veneer.

The veneer is cut with a band saw or mechanical saw. The downside is that it is thick. It cannot be used on the crescent moon.

7. Rolled Veneer

Rolled veneer is a very thin and flat sheet of high quality wood that is bonded to the required size. Adopt a unique method to completely hide the connection. It acts as a flexible and durable decorative coating on furniture edges.

8. Multi Layer Wood Veneer

This veneer foam is a multi-layer material. Made from wood chips. Then it is fixed on a stable elastic base. It has the advantage of offering a variety of unique geometric and abstract motifs.

Multi layer veneer is a unique type of veneer made from natural wood. This type of veneer can be called the most “decorative”. It has a texture that does not look like real wood grain. The color motif of this veneer is a geometric pattern. Many shades are often mixed. Products made from this type of veneer have a contemporary look.

9. 3D Veneer

One of his most popular design techniques is the three-dimensional decorative coating. The 3D veneer has an elegant voluminous pattern with great attention to detail. They are made by combining two thin plywood boards.

This type of veneer takes on the form of various textures during the pressing process. This type of veneer combines state-of-the-art properties with the structure of natural wood.

10. Spliced Veneer

This type of veneer is the production of large surface layers. It is a symmetrical design. The veneer material is made possible by the joining technology. It helps you create fresh and distinctive patterns. This type of veneer is used to reduce waste during the harvesting process.