There are different types of wood joints are used while joining woods together. Wood joints are used to connect various wood components. Wood joints also reduce stress in the wood. In this article, all the important types of wood joints is shown with description.

Table of Contents

Different Types of Wood Joints

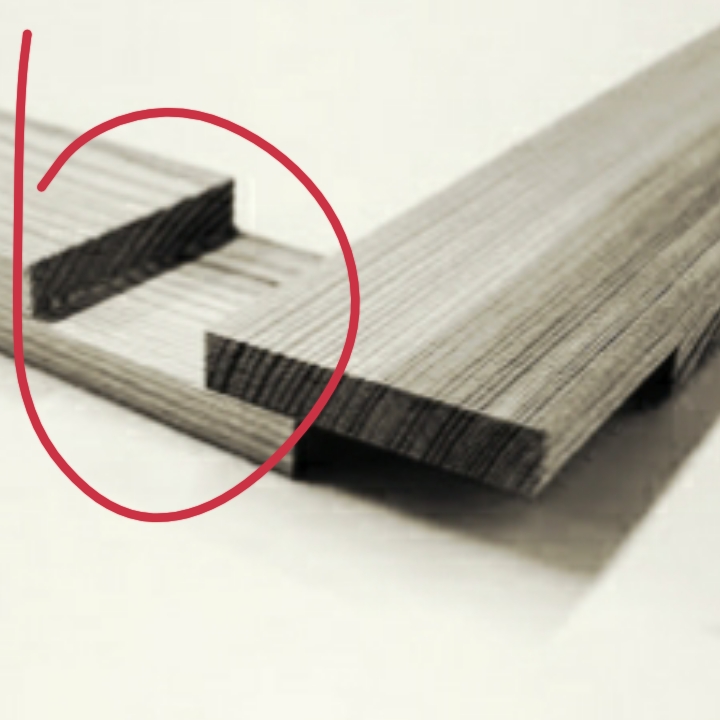

1. Groove Type Wood Joint

A tongue and groove joint is another famous woodworking joint used in flooring, parquet, siding, etc.

These joints consist of a groove or groove on one piece of wood and a tongue or ridge on the other. The tongue slides into the groove to create a strong connection.

2. Dadwood Connection

The dado technique is similar to a tongue and groove joint. The only difference is that dados are cut along the grain, whereas grooves are cut along the grain. Also, the rim is not carved with a tongue. Rather, wide grooves are cut to match the thickness of the other pieces. Dado’s joints are most commonly used in bookcases and other types of shelving.

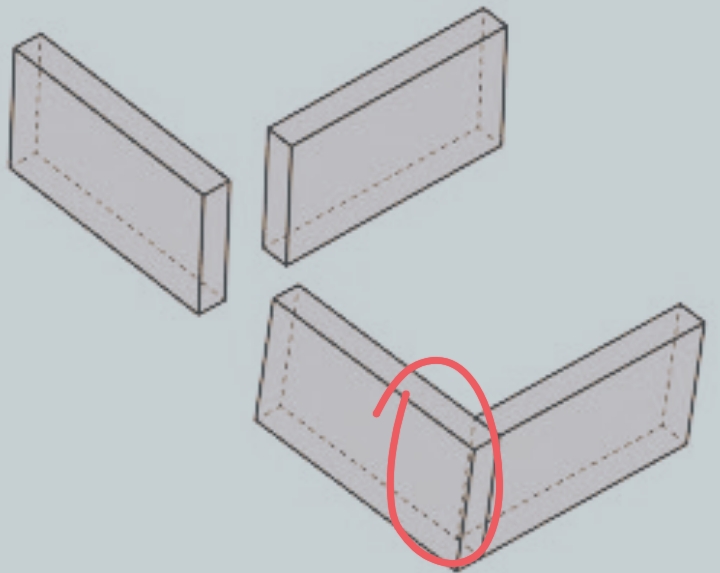

3. Butt Type Wooden Joint

Butt type wood joint is the most simplest type of joint to join various wood components. In this type of joint, edge of the wood panels are joined. Nails and screws are used to create butt joint. Butt joints are very popular in constrution industry. Windows, cabinates and doors are made by using butt joints.

4. Biscuit Type Wood Joint

This joint is an enhanced version of the elliptical butt joint. Biscuits joints are made of pressed and dried wood. Grooves are cut into each end of the piece of wood to hold thin wafers that act as connectors.

After applying the adhesive, the insert will expand to cover the space left by the engraving tool. The advantage of this joint is that it disappears completely, creating a flush surface. Defects in this joint include improper cutting and poor alignment of the biscuit connector mortise lock

5. Rabbet Type Wood Joint

A joint with notches on the ends of the wood. It resembles the protruding edge of a tongue and groove joint, but is cut on one side only. Although it is a simple wooden structure, rebate fittings are more stable than butt fittings.

The most common use for butt joints is to reduce the amount of visible “end grain” that returns to the sides of corners or alcove cabinets. Double seams are ideal when a stronger bond is desired due to their greater surface area.

6. Pocket Hole Wood Joint

Pocket-hole joints use screws to hold a simple head-to-head joint at an angle. The carpenter must pre-drill the space between the two planks. A screw holds the two pieces together and creates a solid, flat surface for the wood.

Blind hole connection is durable and easy to make. Their disadvantage is that they are less aesthetically pleasing than other seals, which makes them suitable for temporary use or situations where the seal is not visible.

7. Wooden Knuckles

One of the most common woodworking joints is the spline joint, often called a box joint. The main purpose of this type of wood joinery is to combine two pieces of wood to create a longer board. Finger joints are very similar to dovetail joints, except that the pins are square instead of diagonal.

Finger joints lack the mechanical strength of dovetails and rely on glue to hold the joint together.

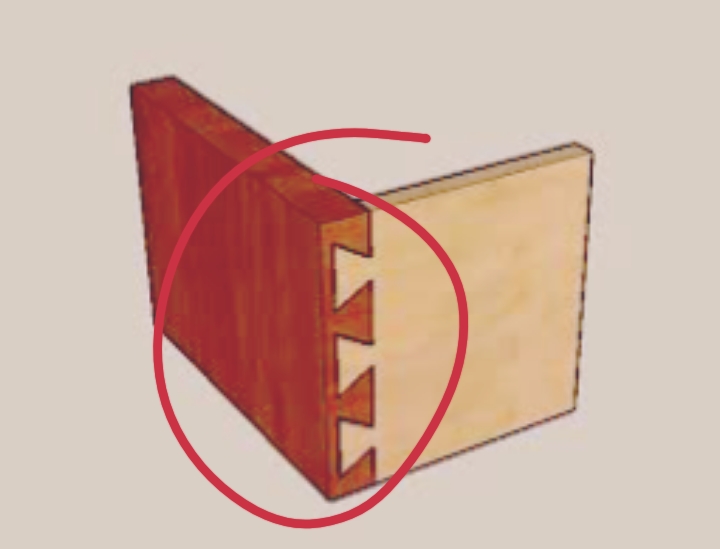

8. Dovetail Wood Joint

This woodworking compound has excellent tensile strength and is very resilient. They consist of several interlocking trapezoidal pins and tails.

Its ability to resist being pulled apart is the most commonly used reason for making drawers. If the connection is glued, it is permanent and does not require mechanical fasteners.

9. Miter Wood Joint

Miters are often used on the outside visible corners of door frames, window frames, and picture frames. Miter is another term for angled cuts, which refers to two 45 degree cuts where two timbers meet to form a 90 degree angle.

They are stronger than butt joints because the two pieces of wood come into contact over a larger surface area, but they require adhesives and mechanical fasteners to stay in place. The advantage of this method is corner strength and a seamless look with no visible grain.

10. Half Lap Wood Joint

Half-wrapping is trimming the overlapping edges of two overlapping pieces of wood to half the thickness. Half-lap joints are stronger than butt joints, but look better because they maintain a constant thickness.

This is typically used when a joint needs to be created in the middle of the timber. Semi-lap joints are widely used in both furniture manufacturing and frame construction.