Table of Contents

Nano Concrete Introduction

The addition of nano-sized particles to concrete can enhance its properties, such as strength, durability, and self-cleaning abilities.

Nano concrete has a denser and stronger material due to the addition of nanoscale particles that fill in the spaces between larger concrete particles.

Nano concrete is more resistant to water and chemical damage due to its lower porosity.

Some nano particles used in nano concrete have photocatalytic properties, which enable self-cleaning abilities by breaking down pollutants and organic matter when exposed to light.

Nanotechnology offers potential for improved sustainability in the construction industry through the use of materials that are less energy-intensive to produce and the reduction of cement and water needed for curing.

Nano concrete has already shown promising results in laboratory testing and is being used in some construction projects around the world to create more durable and sustainable infrastructure.

What Is Nano Concrete?

Portland cement particles less than 500 nanometers in size make up nano concrete. These fine particles fill in the void spaces in the concrete, which results in a denser and stronger concrete.

The compressive strength, tensile strength, and resistance to environmental factors such as corrosion and degradation are all enhanced by the addition of nano-sized particles. Therefore, nano concrete is ideal for constructing high-performance structures like bridges, tunnels, and buildings that require greater strength and durability.

Researchers are still exploring and optimizing the properties and applications of nano concrete, as it is a relatively new technology.

What Are Nano Particles?

The fuse of superfine particles into a Portland-cement paste within a concrete mixture in accordance with the top-down approach of nanotechnology modifies the concrete’s material characteristics and performance by decreasing the void gap between the cement and aggregate in the cured concrete. This enhances concrete strength, durability, shrinkage, and bonding to steel reinforcing bars.

Properties Of Nano Concrete

1. Strength:

Nano concrete has a higher compressive strength than traditional concrete. The addition of nanoparticles improves the packing density of the concrete, which leads to a reduction in the number of voids in the material. This results in a stronger and more durable material.

2. Durability:

Nano concrete has better durability than traditional concrete. The addition of nanoparticles improves the resistance of the material to chemical attacks, freeze-thaw cycles, and abrasion.

3. Workability:

Nano concrete has better workability than traditional concrete. The addition of nanoparticles reduces the viscosity of the material, making it easier to mix and place.

4. Self-healing:

Nano concrete has the ability to self-heal cracks. The addition of nanoparticles allows the material to fill the cracks on its own, improving the durability of the material.

Materials Used In Nano Concrete:

- Carbon Nanotubes.

- Nano Silica.

- Polycarboxylates.

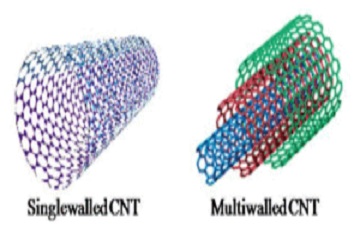

1. Carbon Nanotubes:

Carbon nanotubes made with graphite.

There are two types of carbon nanotubes.

- Single-walled carbon nanotubes

- Multi-walled carbon nanotubes

2. Nano Silica:

Nano silica is the modified form of conventional silica. The particle size of nano-silica is 20 nanometers.

3. Polycarboxylates:

Polycarboxylates is a polymer-based concrete admixture. It is HRVR (high range water reducing admixture) type concrete admixture.

Advantages Of Nano Concrete

- Reduce cost.

- Higher-strength compares to conventional concrete.

- Good workability because the water-cement ratio is very low.

- Saving of cement up to 35%.

- Nanoparticles can fill even micro void.

- Nanoparticles enhance the hydration process.

Disadvantages Of Nano Concrete

- Rare availability of nano materials.

- Rare availability of equipment to produce nano concrete.

Applications And Uses Of Nano Concrete

1. Infrastructure:

Nano concrete can be used in the construction of bridges, tunnels, and other infrastructure projects. The use of nano concrete improves the durability and lifespan of the structures.

2. Buildings:

Nano concrete can be used in the construction of high-rise buildings. The use of nano concrete improves the strength and durability of the buildings.

3. Marine structures:

Nano concrete can be used in the construction of marine structures such as sea walls, jetties, and breakwaters. The use of nano concrete improves the durability of the structures in harsh marine environments.

Faqs

Nanotechnology is a type of science where we study very tiny things that are too small to see with our eyes.

Nano concrete is a type of strong concrete that has special tiny particles added to it to make it even stronger and more durable.

Nano concrete is really strong, lasts a long time, and can fix itself when it cracks.

Nano concrete is made by adding very tiny particles such as silica and carbon nanotubes to the concrete mixture.

Nano concrete is very strong, with a compressive strength of up to 200 megapascals (MPa).

Yes, nano concrete can be used in marine environments such as the ocean because it is very durable and can withstand harsh conditions.

Yes, nano concrete is more expensive than traditional concrete because it has special tiny particles that make it stronger.

Nanotechnology may have some risks, such as the possibility of tiny particles being harmful to humans and the environment.

Nanotechnology will help make construction materials even stronger and more durable, so buildings can last even longer and be more safe for people to live and work in.