Water-cement ratio is very crucial for the perspective of strength. Proper water-cement ratio is used to make concrete durable.

In this article, I will discuss water cement ratio in detail.

Let’s start!

Have your senior boss on the construction site told you that “Add some water, the concrete looks extremely hard”?

What do you think?

Do you think Adding more water at the site level increases the concrete workability?

Well, the answer is NO!

Let us discuss what is Water-Cement Ratio.

Table of Contents

What is Water-Cement Ratio?

The water-cement ratio is the weight of water to the weight of cement in the concrete mix. The water-cement ratio directly influences the strength of concrete. To achieve a higher strength of concrete, a lower Water Cement ratio is used, along with a plasticizer or superplasticizer to increase workability.

A proper water-cement ratio also increases the durability of the structure. When we calculate the water-cement ratio, other cementitious ingredients like fly ash, blast-furnace slag, silica fume, rice husk ash, and pozzolana are also included in the cement if we add these materials.

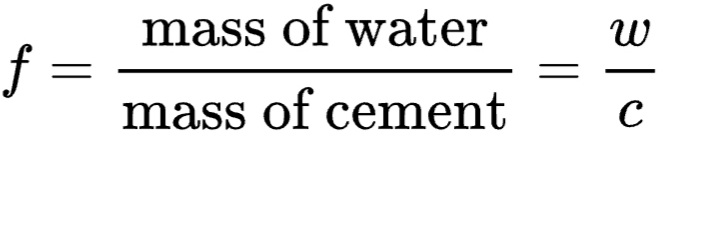

Water-cement ratio = weight of water/weight of cement

According to The American Concrete Institute (ACI) 318 and ACI 332, the maximum water-cement ratio is specified is 0.45.

According to Uniform Building Code 1997, the maximum water-cement ratio is 0.50 if the concrete is exposed to freezing and thawing in a moist condition or to de-icing chemicals.

Maximum of 0.45 water-cement ratio for concrete in a severe or very severe sulfate condition.

Water Cement Ratio Formula

Importance Of Water-Cement Ratio?

The preparation of concrete is directly affected by the water-cement ratio, making it an important factor. The quality and properties of the hardened concrete depend on it as well. A good concrete mix needs to be as compact and dense as possible, which means using as little water as possible, while still hydrating the cement minerals and allowing for proper handling.

The ratio of the weight of water to the weight of cement used in a concrete mix is known as the water-cement ratio. Higher strength and durability are achieved with a lower ratio, but it may make the mix more difficult to work with and form. The use of plasticizers or super-plasticizers can resolve issues with workability. On the other hand, a higher ratio results in a too fluid concrete mix that leads to a porous hardened concrete of poor quality.

Cementitious materials, including cement and supplementary cementitious materials like ground granulated blast-furnace slag (GGBFS), fly ash (FA), silica fume (SF), rice husk ash (RHA), metakaolin (MK), and natural pozzolans, are utilized. These supplementary cementitious materials have interesting hydraulic binding properties and are byproducts of other industries.

The 1997 Uniform Building Code mandates a maximum water-cement ratio of 0.5 when concrete is exposed to freezing and thawing in moist conditions or to de-icing salts. Additionally, a maximum ratio of 0.45 is required for concrete in severe or very severe sulfate conditions.

Water-Cement Ratio Table

| Exposure | Plain Cement Ratio | Reinforced Cement Concrete | ||||

| IS 10262 | Minimum Cement Content | W/C Ratio | Conc. Grade | Minimum Cement Content | W/C Ratio | Conc. Grade |

| Mild | 220 | 0.60 | 300 | 0.55 | M20 | |

| Moderate | 240 | 0.60 | M15 | 300 | 0.50 | M25 |

| Severe | 250 | 0.50 | M20 | 320 | 0.45 | M30 |

| Very Severe | 260 | 0.45 | M20 | 340 | 0.45 | M35 |

| Extreme | 280 | 0.40 | M25 | 360 | 0.40 | M40 |

What Will Happen If We Use High Water-Cement Ratio?

In the high water-cement ratio quantity of water is high. This excessive quantity of water leads to the segregation of concrete.

The extra water that is not consumed may leave concrete when it hardens and can cause bleeding in concrete. Bleeding reduces the final strength of concrete.

Mixing an excessive quantity of water causes more shrinkage when the water is left, resulting in concrete cracks which also decrease the strength of concrete.

What Will Happen If We Use Low Water-Cement Ratio?

Using very low amounts of water when mixing concrete will result in a mix that is too dry and difficult to work with. The chemical reaction that occurs during the curing process, which hardens the concrete and gives it its strength, requires water as an essential ingredient. If there is not enough water present, the reaction will not proceed properly, resulting in weak and easily cracked concrete.

Poor workability is another consequence of a low water-cement ratio in the concrete mix, making it challenging to place, compact, and finish. Insufficient compaction may also occur, leading to the formation of voids and weak spots in the hardened concrete.

Furthermore, low water content in concrete can decrease its durability and increase its permeability, allowing water and other substances to seep into the concrete and cause damage over time. In extreme cases, the concrete may fail entirely, necessitating replacement.

Therefore, it is crucial to use the appropriate amount of water when mixing concrete to ensure that it possesses the necessary strength and durability for its intended application.

Faqs

A high water-cement ratio leads to weaker, less durable concrete with increased porosity, shrinkage, and cracking.

No, the water-cement ratio cannot be adjusted once the concrete is mixed. The ratio must be carefully measured and proportioned before pouring the concrete.

Higher water-cement ratios lead to more fluid and workable concrete, but can also result in weaker and less durable concrete. The desired workability must be balanced with the need for strength and durability when determining the appropriate water-cement ratio.