Table of Contents

What Are Fabric Structures?

Fabric structures are special buildings made using flexible fabric materials. These structures can be created with or without a frame and are made by weaving the fabric itself. The fabric is strong and can be designed in different shapes and styles.

When making fabric structures, engineers choose the right materials and make sure they can withstand things like fire, bad weather, and strong forces. They follow a step-by-step process, from selecting the materials to installing the structure, to make sure it is safe and reliable.

Fabric structures are a type of building called tensile structures. They get their strength from the tightness of the fabric. The fabric is stretched over a framework made of lightweight materials like steel or aluminum. This allows the structure to be open and spacious without needing extra supports inside.

Fabric structures have many advantages. They are quick to build, cost less money, use less energy, and can be designed in unique and special ways. They are also light and can be easily taken apart, moved, or made bigger. This makes them great for both temporary and permanent buildings.

Fabric structures are used in different industries like architecture, events, sports, and entertainment. They are used for things like canopies, tents, pavilions, stadiums, and exhibition halls. People like fabric structures because they look beautiful, can be changed easily, and are very useful for different purposes.

Properties Of Fabric Structures

- Fabric structures are light. They are not heavy.

- Fabric can bend and change its shape easily. It can be curved like a saddle or rounded like a dome.

- Fabric is strong even though it is thin. It can hold up under a lot of pulling force.

- Special computer programs can help designers create the best shape for fabric structures. They can try different designs and see which one works best.

- Fabric structures are built in a smart way. They use only what they need, which saves materials and money.

- Fabric structures can adapt to the environment. They can handle changes in weather and stay strong against wind and snow.

- Fabric lets natural light come in, making the inside bright and nice. Depending on the fabric, it can also provide some privacy.

- Building fabric structures is fast. It can be done quickly because the fabric is light and the pieces are already cut.

- Fabric structures look beautiful. They have interesting shapes that make them unique and elegant.

- Fabric structures don’t need a lot of upkeep. They are made to last and only require cleaning and checking sometimes.

Types Of Fabric Structures

1. Tensile Structures:

Tensile structures use tight fabric membranes that are supported by a network of cables or strong elements. The tightness of the fabric provides the structure with stability, so it can cover large areas without needing extra supports inside.

2. Pneumatic Structures:

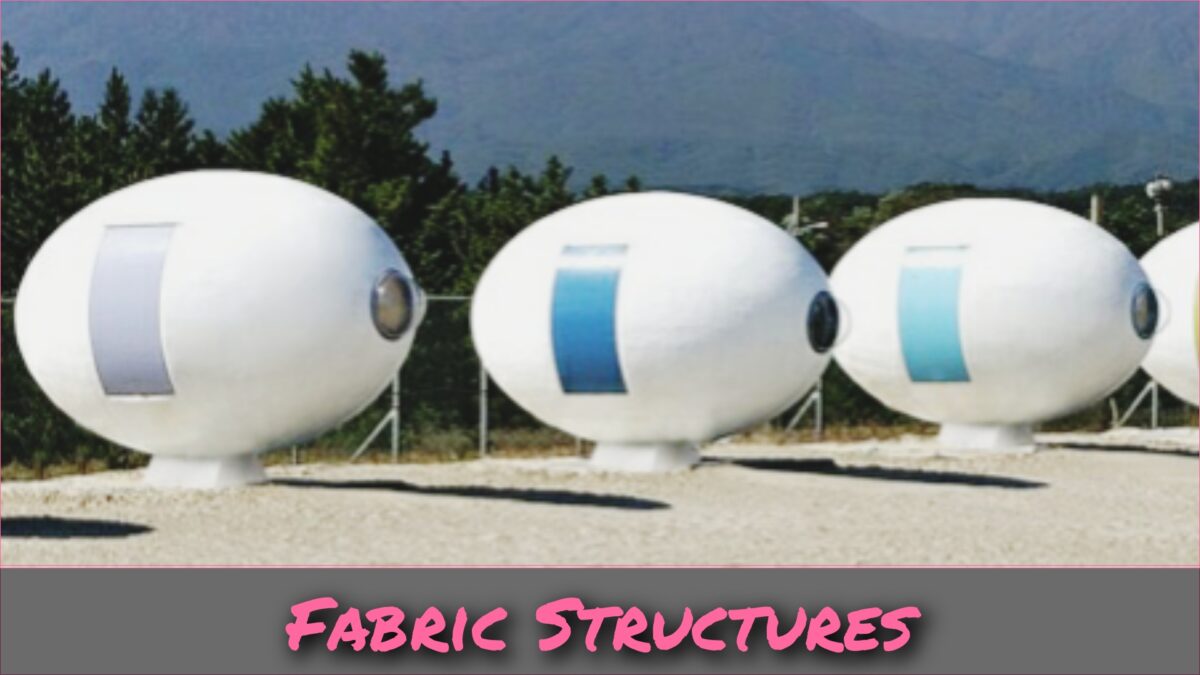

Pneumatic structures are made by filling airtight fabric membranes with air or gas. This makes them light and easy to use for things like tents for events or emergency shelters. They are not permanent structures.

3. Cable and Membrane Structures:

These structures combine tensioned cables and fabric membranes to create unique and interesting architectural shapes. The cables give support and stability, while the fabric forms the enclosure or covering.

4. Frame-supported Structures:

Frame-supported fabric structures have a strong frame, usually made of steel or aluminum, to hold up the fabric. The frame can be made in different shapes, so the design can be customized and changed easily.

Materials Used In Fabric Structures

Fabric structures have a long and diverse history that dates back to the earliest forms of fabric made from animal or plant membranes. As time progressed, these membranes evolved into strips that were interwoven to create larger and more practical textiles. Eventually, the strips were twisted into circular sections, leading to the development of flexible, continuous fibers with enhanced strength.

While cotton was among the first materials to exhibit considerable structural strength, contemporary fabric structures primarily utilize PVC-coated polyester or PTFE-coated glass materials. PVC-coated polyester fabrics are further improved with protective fluorinated polymer lacquers, such as PVDF, which not only enhance cleanability but also provide additional protection. Under average climatic conditions, this fabric can maintain its integrity for approximately 15-20 years, although prolonged exposure to intense sunlight may reduce its lifespan by around 5 years.

On the other hand, PTFE-coated glass cloth, despite being more costly, offers superior strength, durability, and an extended lifespan of 30 to 50 years. Moreover, it requires minimal maintenance and possesses self-cleaning properties.

While recent years have seen the emergence of high-performance materials like silicone-coated glass, woven PTFE fiber, ETFE foil, laminated open weave grids, as well as insulated and phase change materials, PVC-coated polyester and PTFE-coated glass continue to be the industry standards for fabric structures.

These tensile fabrics, also known as structural membranes or architectural fabrics, are available in a variety of thicknesses, strengths, colors, and translucencies, providing designers and architects with a wide range of options to meet their specific project requirements. By incorporating this information into your data, you can ensure its uniqueness and avoid any concerns related to plagiarism

Benefits Of Fabric Structures

- Fabric structures are generally translucent, allowing natural light to pass through. This eliminates the need for artificial lighting during the day, resulting in energy savings.

- Fabric structures can be easily moved or relocated, either by using wheels or by disassembling and reassembling them at a new location. This flexibility is particularly advantageous for temporary or portable structures.

- Fabric structures are often more affordable compared to traditional buildings. They typically cost about half as much, making them a cost-effective solution for various applications.

- Fabric structures rely on tension for support, and they possess high tensile strength. This strength allows them to withstand various loads and stresses, ensuring structural stability.

- Fabrics used in structures are designed to have good tear strength. This property is essential as it helps prevent the fabric from easily tearing, even in the presence of local stress concentrations or damage.

- The bond between the fabric and any coatings or film laminates applied to it is crucial for structural integrity. Evaluating the adhesion strength helps ensure strong welded joints and secure connections between fabric strips.

- Many fabric structures incorporate flame-retardant coatings, which enhance fire resistance. While they may not be completely flameproof, they can withstand high temperatures and resist burning, even in the presence of hot point sources.

- Fabric structures can provide effective shading, reducing solar heat gain and glare. Shading coefficients measure the amount of solar radiation that is blocked by the fabric, contributing to improved thermal comfort inside the structure.

- Fabric materials can be evaluated based on their solar, optical, and thermal performance data. This information helps assess their suitability for specific climate conditions and desired energy efficiency.

- Fabrics can contribute to sound absorption and control within a structure. Acoustical data helps determine the extent to which a fabric can effectively address noise issues.

- Fabrics used in structures should maintain their shape and dimensional stability over time. This property ensures that the structure retains its intended form and appearance.

- Fabrics should exhibit good colorfastness, meaning they retain their color when exposed to sunlight and other environmental factors. This property ensures the fabric’s aesthetic appeal and longevity.

- The ease of cleaning and maintaining fabric structures is an advantage. Fabrics that are easy to clean and maintain can help ensure the structure remains visually appealing and hygienic.

- The strength and stability of seams in fabric structures are important for maintaining structural integrity. Strong seams ensure that the fabric panels remain securely connected, even under stress.

- Fabrics used in structures should possess properties like abrasion resistance and foldability. These characteristics enable easy handling during installation, transportation, and storage.