Flue-gas desulfurization (FGD) is a set of technologies used to remove harmful gas such as sulfur dioxide from exhaust flue gases of fossil-fuel power plants.

In this technique, sulfur dioxide is also removed from the emissions of other sulfur oxide emitting processes such as waste incineration.

In the Flue-Gas Desulfurization process, wastewater is produced, this wastewater must be treated before disposal.

FGD wastewater contains high quantities of sulfates, calcium, magnesium, heavy metals, TSS, and ammonia. There should be zero Liquid Discharge (ZLD) treatment for the wastewater.

Sulfuric Acid Mist Formation

Fossil fuels, for example, coal and oil can contain a lot of sulfur. When fossil fuels are burned, around 95% or a greater amount of the sulfur is for the most part changed over to sulfur dioxide (SO2). Such transformation occurs under ordinary states of temperature and of oxygen present in the flue gas. Nonetheless, there are conditions under which such chemical reactions may not occur.

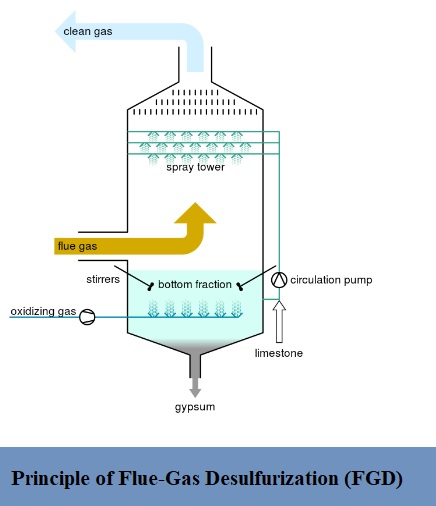

The Principle of Flue-Gas Desulfurization (FGD):

Normally, there are two stages of FGD. In the first stage fly ash and in the second stage sulfur dioxide (SO2) is removed.

In a wet scrubbing system, the flue gas passes through a fly ash removal machine. After that flue gas passes into the SO2-absorber.

In the dry injection technique, sulfur dioxide (SO2 ) is first reacted with the lime, and then the flue gas passes through a particulate control device.