Whenever two or more than two gears mesh with each other to operate then it is called the gear train. In gear trains, we can use the “n” number of gears according to our needs to transmit the power. There are various types of gears that are available to transmit the torque from one shaft to another. The types of gear supposed to be used in an operation depend on the velocity ratio requirements.

A gear train can have spur gear, helical gear, bevel gear, etc. according to the axis of the shaft through which we have to transmit the power.

Table of Contents

Gear Train Types:

- Simple Gear Train

- Compound Gear Train

- Reverted Gear Train

- Epicyclic Gear Train

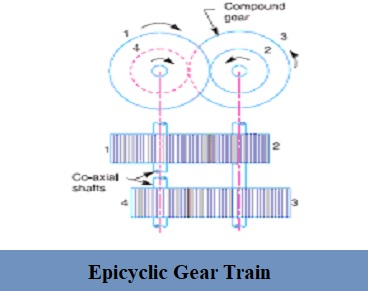

1. Simple Gear Train:

Simple gear train arrangements can be defined as when every gear have their own shafts. That means each gear has one shaft in a simple gear train. So, suppose there are four gears in a simple gear train then there will be four shafts for each gear. That’s why this arrangement is called the simple gear train.

There are two types of Simple gear trains as given below.

- (I) Driver Gear

- (II) Driven Gear

(I) Driver Gear

The driver gear is the main or primary gear that actually drives the other gears present in the gear train.

(II) Driven Gear

The driven gear is a second gear that is driven by the driver gear directly or indirectly with the help of intermediate gears. The driven gear is also known as the follower gear.

The direction of the motion of the driver gear and driven gear are opposite.

Speed Ratio:

To understand the speed ratio let’s take an example of a simple gear train which have only two gears namely A and B. Now let’s say gear A is a drive gear and it has N1 speed with a T1 number of teeth. While gear B is driven gear, it has N2 speed with a T2 number of teeth.

So now the speed ratio of the gear train can be defined as the ratio between the speed of the driver gear to the speed of the driven gear.

Speed Ratio = N1/N2 = Speed Of Driver Gear/Speed Of Driven Gear

The speed ratio of the gear train can be also defined as the ratio between the number of teeth of the driven gear to the number of teeth of the driver gear.

Speed Ratio = T2/T1= Number Of Teeth Of Driven Gear/Number Of Teeth Of Driver Gear

Speed Ratio = N1/N2= T2/T1

Train Value:

If we take the reciprocal of the speed ratio of the gear train, then we can get train value.

Train Value = N2/N1= T1/T2 = Speed Of Driven Gear/Speed Of Driver Gear = Number Of Teeth Of Driver Gear/Number Of Teeth Of Driven Gear

Now suppose we have three gears namely A, B, and C in a simple gear train. Where A is a driver gear with N1 speed and T1 number of teeth. B is an intermediate gear with N2 speed and a T2 number of teeth. C is the driven gear with N3 speed and T3 number of teeth.

Now Speed Ratio –

Since gear A meshes with gear B.

N1/N2= T2/T1

And gear B meshes with gear C.

So, N2/N3 = T3/T2

Now we can obtain the speed ratio of this gear train by multiplying both the equations together –

N1/N2 X N2/N3 = T2/T1 X T3/T2

Speed Ratio – N1/N3 = T3/T1

Similarly, we will take the reciprocal of speed ratio to find train value.

Train Value = N3/N1 = T1/T3

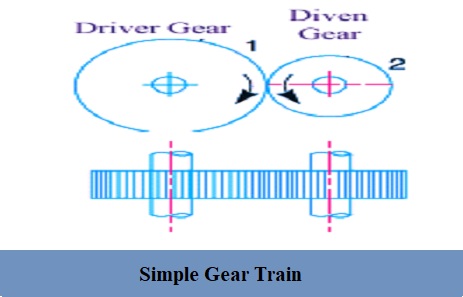

2. Compound Gear Train

Compound gear train arrangements can be defined as when a shaft has more than one gear. That means a single shaft will have two or more gears in a compound gear train.

Speed Ratio = First Driver Gear Speed/ Last Driven Gear Speed = Product Of Number Of Teeth Of Driven Gear / Product Of Number Of Teeth Of Driver Gear

Train Value = Last Driven Gear Speed / First Driver Gear Speed = Product Of Number Of Teeth Of Driver Gear / Product Of Number Of Teeth Of Driven Gear

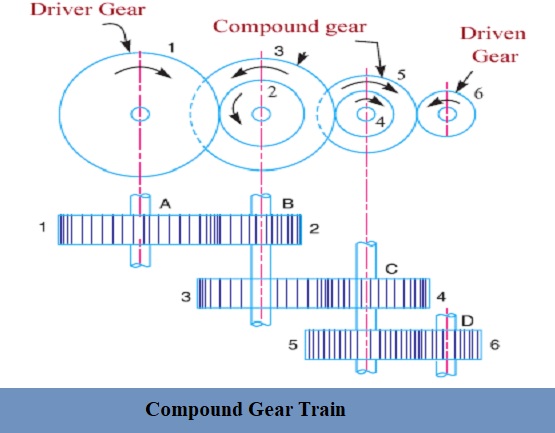

3. Reverted Gear Train:

Reverted gear train arrangements can be defined when the first drive gear and last driven gear are on a common axis. The speed ratio and train value for reverted gear train can be found using the same formula which we have used for compound gear train.

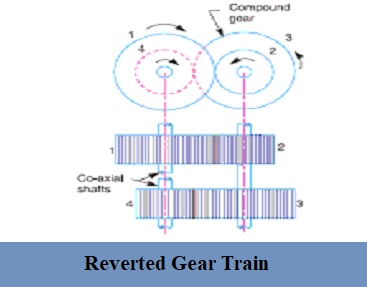

4. Epicyclic Gear Train:

Epicyclic gear train arrangements can be defined when gears move from a relatively fixed point with the help of the axis of the shaft on which it is mounted. The epicyclic gear train arrangements are used when we required a high-velocity ratio. The speed ratio and train value of for epicyclic gear train can be found using the same formula which we have used for the compound gear train.