Jet grouting is used for soil stability. In this blog post, I will discuss jet grouting in detail.

In the modern construction, stability of soil is very important to bear the high amount load.

Jet grouting has a long past history as a ground improvement technique. Even in the present scenario, the demand of jet grouting is high.

Table of Contents

What is Jet Grouting?

In this process, stabilizing fluid is injected into the soil. Injected fluid have have pressure and high velocity.

Site should be ready before injection process and all the equipments should be inspected.

When injected fluid entered into soil, it becomes hard. This hard material provides stability to the soil. The grouted materials make column type structure. These columns are known as jet grouted column.

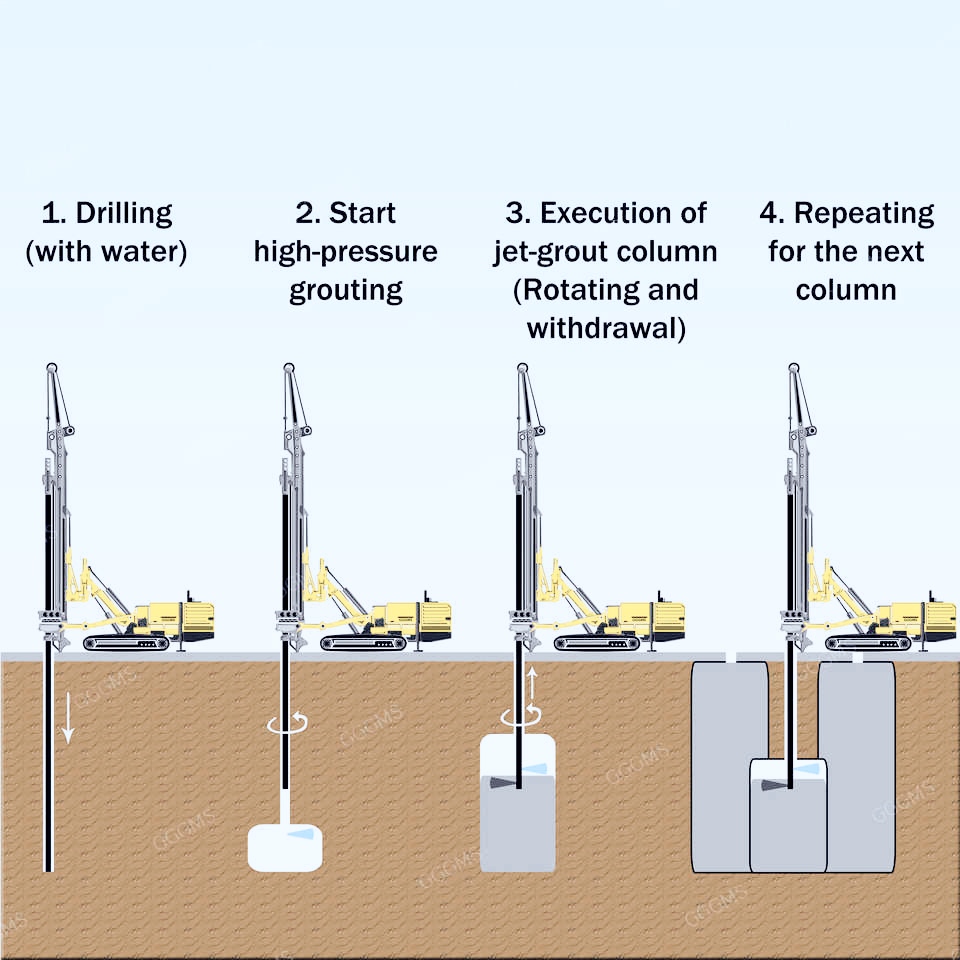

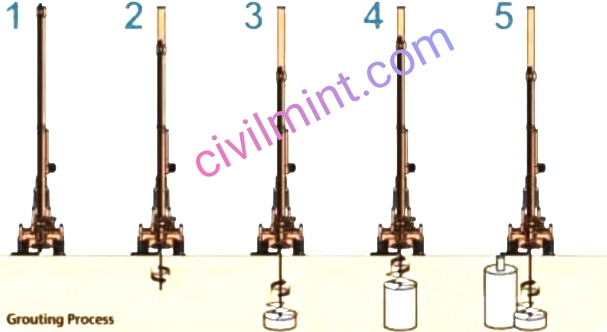

Jet Grouting Procedure

In the first step, the area is inspected and low strength soil is identified. After that, drilling operation is conducted. Holes are constructed in the subsoil. The holes depth are depend upon the strength of soil. If soil is not much week, swallow holes are constructed. In case of subsoil are very week, deep holes are constructed.

After hole construction, injection grouting can be started. The grouting equipment comprises of a jet grouting string of almost 7 to 10 cm diameter. The grouting is done by using a nozzle. Diameter of nozzle is small. Its diam varies from 1 mm to 10 mm. Due to small diameter, velocity of injected fluid is very high.

When process is started, the string must be raised and rotated very slowly to seal the complete column surface with the soil and the fluid system that has to be injected.

Now jetting process starts. In this process, fluid is injected in the subsoil and main string kept raised.

When the process is going on, a part of mud within the pit created and mix fluid rises in the upward direction, this mix fluid is known as spoil. It gives an idea that the bottom is fully sealed with the grout and soil mix.

String raising can be done at a distance of 40 mm to 100 mm. This distance is depend on the depth of subsoil treatment. Rotation must be performed for each raising. There are some systems in which raising is done parallel to the string rotation.

The speed of the rotating arm should be uniform. A constant speed of the rotating equipment gives a properly refined grouting column.

Jet Grouting Methods

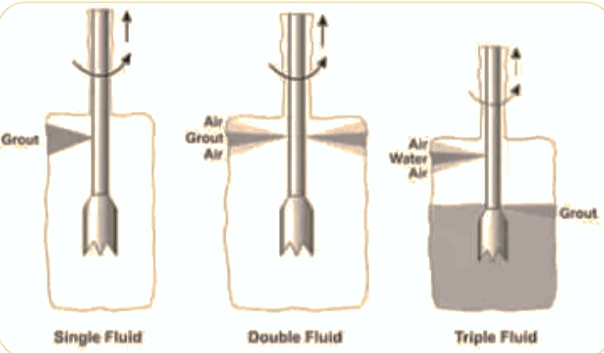

Normally, three are used for injection grout process. These methods are as follows:

- Single fluid systems

- Double fluid systems

- Triple fluid systems

These three systems are based on the number of fluid used in grouting process.

These fluids are classified as:

- Grout i.e. Water + Cement for single fluid.

- Air and Grout for double fluid.

- Water, air and grout for triple fluid system.

Different types of pipes are used in the jet grouting strings. Selection of pipes depend on the numbers of fluids used in the process.

Various types of pipes are shown in the below figure.

1. Single Fluid Jet Grouting System

In this type of jet grouting, water-cement paste is work as a grouting material. This water-cement paste is injected with the help of nozzles. In this type of grouting, soil remolding and subsequent cementation are done by the same fluid. This cement paste is used to remove the spoil. This water-cement grout provides stability to the soil.

The main drawback of single fluid system is that it lost huge amount of kinetic energy in the process. It is very difficult to penetrate soil for a single fluid system.

2. Double Fluid Jet Grouting System (H3)

This system also use water-cement as a grouting material but the main.difference is application of air jet.

Air jet is used to displace the subsoil and reduce the friction. Hence, there is very little loss of kinetic energy.

3. Triple Fluid Jet Grouting System

In this type of jet grouting system, two jets are used to displace the subsoil. High velocity water jet and air jet are used for soil loosening. The water jet is operates with help of coaxial air jet, supplied by an annular nozzle similar to the one used for the double system.

This grout of water-cement is then taken from a separate nozzle. The grout material is kept on the lower part of the monitor. The primary purpose of grout is in cementing the soil previously remolded by the water jet . This is the reason the grout is delivered at a lower velocity.

Applications of Jet Grouting

Jet grouting finds is a method of ground improvement and finds applications in the following:

- Construction of Horizontal Barrier

- Control of groundwater

- Underpinning

- Tunneling

- Support for excavation

Advantages of Jet Grouting

Formation of large cement columns without large soil movements (subsoil).

Pillars form continuous elements that are formed into various shapes to improve mechanical properties and reduce porosity.

Improving the building process through improved design philosophies.

Attractive for working in tight spaces and difficult site conditions.