Table of Contents

What is Mechanical Power Transmission?

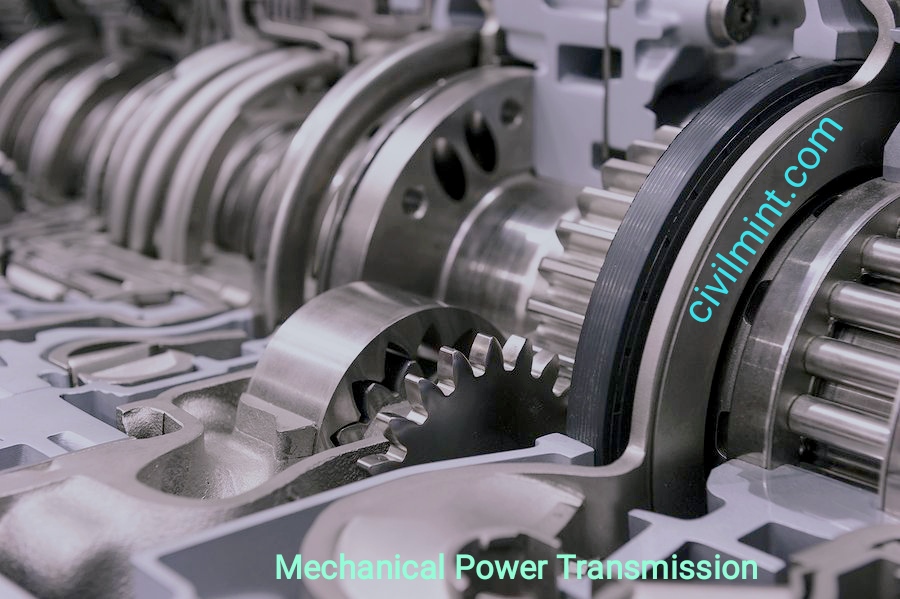

Mechanical power transmission is the transmission of energy to where simple machines, linkages and mechanical transmissions are used to do work.

Almost all machines have some form of power and motion transmission from an input source. This is usually an electric motor or an internal combustion engine, usually providing rotary drive torque through an input shaft and clutch combination.

Importance of Mechanical Power System

Electricity can be produced in different ways but sometimes you can’t get it where you need it, or in the right shape, direction, or size. Electrical and mechanical power transmission is therefore of great importance to technical product design.

Machines use a variety of systems, including gear drives, shaft couplings, belt drives, and chain drives, which consist of interconnected power transmission components to deliver power where it is needed.

Components of Power Transmission System

1. Shaft

A mechanical shaft is a mechanical power transmission element that transmits power and rotary motion from one device to another. Shaft design is critical to avoid premature failure and designers must consider common failure modes.

2. Couplings

Couplings, also called shaft couplings, are used to connect two shaft ends to transmit both angular rotation and torque. A major design requirement for couplings and their retaining devices is that the rated torque must be transmitted without slippage, premature failure, or possibly misalignment.

3. Power screw

A power screw is used as a connecting element for transmitting power in technological products such as machines that convert rotaries. A large sliding contact area between the male and female threads provides a greater mechanical advantage than a small wedge angle.

These are not used in high power transmissions due to high frictional energy losses in the threads.

4. Gear Trains

A gear train is a set of multiple gears that transmit power. A gear train is a mechanical power transmission system in which the gears are mounted on a shaft so that the teeth of the meshing gears mesh with each other and roll on the pitch diameter.

4. Brakes and Cluthes

Theoretically, brakes and clutches are almost indistinguishable, but functionally a clutch is a connection between two connecting shafts moving at different speeds on a common axis of rotation.

A clutch used to connect and disconnect the power transmitted by the The main function of the clutch is to bring both elements to a common angular velocity.

The brake works similarly, but one of the elements is fixed, resulting in a common angular velocity of zero when applied.

5. Chains

Chains are used in low speed applications where the distance between shafts is too far apart to use a gear train and belt to support the transmitted torque. It’s also a great power transmission option when a precise RPM ratio is required