A Pile foundation is a type of deep foundation in which a thin member made of steel, concrete, or wood is inserted into Soil having a low bearing capacity for transferring the load of a superstructure. The load can be transferred to a strong soil layer by skin friction or by end bearing.

Plie Foundations are used where soil have low bearing capacity.

Table of Contents

Uses of Pile Foundation

Pile foundation can be used for the situations as follows

- If the groundwater table is high.

- In the case of non-uniform and heavy load transfer from the superstructure.

- When soil is compressible.

- In the case of scouring due to the river bed.

- Where the bearing capacity of the soil is less to hold the structure.

Types Of Pile Foundation

- Driven Pile Foundations

- Cast-in-situ Pile Foundations

- Driven and Cast-in-situ Piles

Let us discuss each type of pile foundation in detail.

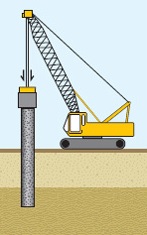

1. Driven Pile Foundations

Driven pile foundations can be made from different materials such as concrete, steel, or timber. These piles are prefabricated before placing at the construction site. When driven piles are made of concrete, they are precast. These piles are driven using a pile hammer.

When these piles are driven into the granular soils, they displace an equal volume of soil. This helps in the compaction of soil around the sides of piles and results in the densification of soil. The piles which compact the soil adjacent to it is also called compaction pile. This compaction of soil increases its bearing capacity.

Saturated silty soils and cohesive soils have poor drainage capability. Thus these soils are not compacted when driven piles are drilled through them. The water has to be drained for the soil to be compacted. Thus stresses that are developed adjacent to the piles have to be borne by pore water only. This results in an increase in pore water pressure and a decrease in the bearing capacity of the soil.

2. Cast-in-situ Pile Foundations

Cast-in-situ piles are concrete piles. These piles are constructed by drilling holes in the ground to the required depth and then filling the hole with concrete. Reinforcements are also used in the concrete as per the requirements. These piles are of small diameter compared to drilled piers.

Cast-in-situ piles are straight bored piles or with one or more bulbs at intervals are cast. The piles with one or more bulbs are called under-reamed piles.

3. Driven and Cast-in-situ Piles

Driven and cast-in-situ piles have the advantages of both driven and cast-in-situ piles. The procedure for installing a driven and cast-in-situ pile is as follows:

A steel shell of the diameter of the pile is driven into the ground with the aid of a mandrel inserted into the shell. After driving the shell, the mandrel is removed and concrete is poured into the shell.

The shell is made of corrugated and reinforced thin sheet steel (monotube piles) or pipes. The piles of this type are called shell-type piles.

The shell-less type is formed by withdrawing the shell while the concrete is being placed. In both types of piles, the bottom of the shell is closed with a conical tip which can be separated from the shell. By driving the concrete out of the shell an enlarged bulb may be formed in both types of piles. Franki piles are of this type. In some cases, the shell will be left in place and the tube is concreted. This type of pile is very much used in piling over water.