In this article I will discuss about ‘Saudi Aramco Hot Work Permit’.

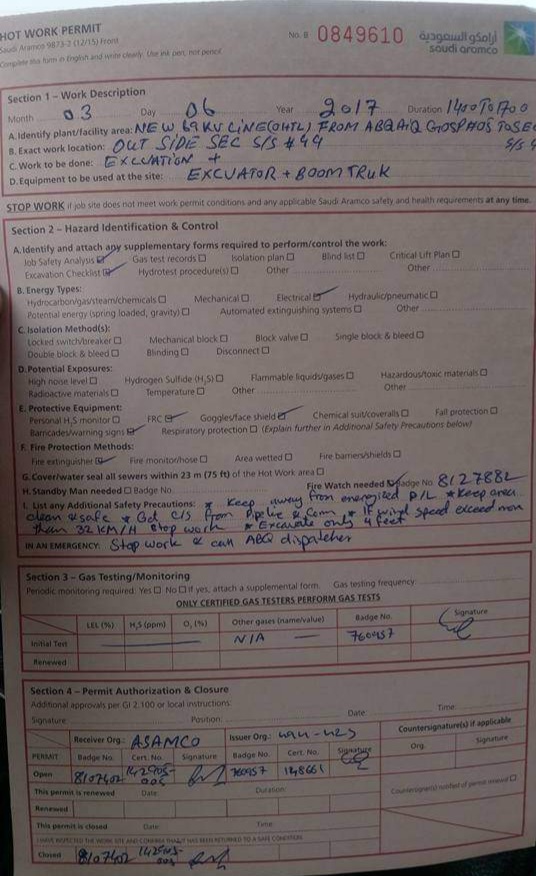

See the below image of Saudi Aramco Hot Work Permit.

Table of Contents

Introduction

In industries like oil and gas, construction, and manufacturing, workers often perform hot work activities that involve welding, cutting, and the use of tools that produce sparks and heat. To keep these activities safe, Saudi Aramco, a major energy company, has established a comprehensive Hot Work Permit (HWP) process.

Explanation

Hot work activities can ignite flammable materials, making safety a top priority. Saudi Aramco’s HWP process is designed to reduce these risks, ensuring the safety of workers and the workplace.

Before starting hot work, workers must actively identify potential hazards. This includes determining what materials could catch fire, where sparks might come from, and what could go wrong if safety measures are not in place.

Once hazards are identified, workers actively assess their severity. This step considers the types of flammable materials nearby, possible ignition sources, and the potential consequences of accidents.

After identifying risks, workers must actively come up with ways to make the work safer. This can involve using fire extinguishers, fire blankets, and ensuring that flammable materials are a safe distance away.

To actively control potential fires during hot work, workers must choose the right fire extinguisher and understand how to use it. Fire blankets are also used to suppress flames safely.

Before beginning hot work, workers actively seek approval from an authorized person. This individual ensures that all safety precautions are in place.

The authorized person actively plays a pivotal role in the HWP process. They are responsible for overseeing and approving hot work activities to ensure safety.

Key Components Hot Work Permit

1. Documenting Safety

The HWP form actively captures essential safety information, serving as a foundational document for hot work activities.

2. Work Description

A comprehensive work description, including location, equipment, and materials, actively lays the foundation for the HWP.

3. Hazards Identification and Controls

Workers actively document identified hazards and the controls in place, aiding in both planning and emergency responses.

4. Gas Testing and Monitoring

Active gas testing and monitoring procedures are described to ensure the work area remains safe from flammable gases and vapors.

5. Permit Authorization and Closure

Active signatures from the authorized person and the work permit applicant, along with dates, actively signify commitment to safety and the finalization of the safety process.

Saudi Aramco Hot Work Permit Requirements

1. Meeting Safety Standards

To obtain an HWP, workers actively meet prerequisites, establishing a robust foundation for safety.

2. Qualified Work Permit Reciever

Active emphasis is placed on qualifications and training for work permit applicants, ensuring they are well-prepared for hot work safety.

3. Work Area Inspection

Active explanation of the inspection process led by the authorized person, ensuring the work area actively meets safety standards.

4. Taking Active Safety Precautions

Active implementation of safety precautions, including using fire extinguishers, fire blankets, and ensuring there are no flammable gases and vapors.

5. The Significance of Active Signatures

Active signatures from the work permit issuer person and the work permit reciever actively demonstrate their commitment to safety.

Best Practices for Hot Work Safety

1. Proactive Safety Measures

In addition to the HWP process, workers should actively follow best practices to enhance safety during hot work activities.

2. Accessibility of Fire Extinguishers and Fire Blankets

Active placement of fire extinguishers and fire blankets within reach ensures a swift response to potential fire hazards.

3. Isolating Flammable Materials

Actively removing or isolating flammable materials from the work area is crucial in preventing accidents.

4. Gas Purging

Active purging of flammable gases and vapors from the work area before starting work is a critical safety step.

5. Use of Spark-Resistant Tools

Workers should actively use spark-resistant tools and equipment to reduce the risk of ignition during hot work.

6. Continuous Monitoring

Active monitoring of the work area for signs of fire or explosion is essential for preventing accidents.

7. Rapid Response

Active preparedness to extinguish fires during hot work is crucial, with training and emergency response plans playing a significant role.

Putting the HWP Process into Action

1. A Real-Life Safety Procedure

Walk actively through the Saudi Aramco HWP process in a real-life scenario to provide a practical understanding.

2. Completing the HWP Form

Describe actively the step-by-step process of completing the HWP form and submitting it to the authorized person.

3. Work Area Inspection and Approval

Explain actively how the authorized person inspects and approves the HWP, emphasizing its critical role.

4. Commencing Work

Active discussion of how the work permit applicant actively signs the HWP and begins work only after securing authorization.

5. Actively Gas Monitoring

Active explanation of the role of the work permit applicant in actively monitoring the work area for signs of fire or explosion during hot work activities.

6. Closure of the HWP

Detail actively the process of closing out the HWP, including the final signature of the work permit reciever and its active importance in ensuring safety.

Read this: Salary of WPR Aramco

Wrap Up!

Saudi Aramco Hot Work Permit process is not just a set of rules; it’s a commitment to safety. It empowers workers to actively identify risks, take necessary precautions, and secure authorization before performing hot work.

Read also: EOLB Permit

By following this process and actively embracing safety practices, workplaces can foster a culture of safety, ensuring the well-being of workers and the protection of valuable assets.