Glass is a very popular material in modern construction. As the construction industry grows, there are various types of glasses emerge in the construction industry.

Table of Contents

Types Of Glasses

Here is the list of important types of glasses used in construction.

- Float glass.

- Shatterproof glass.

- Laminated glass.

- Extra clean glass.

- Chromatic glass.

- Tinted glass.

- Toughened glass.

- Glass blocks

- Annealed Glass

- Heat Strengthen glass

Here we are providing brief information about the most common types of glasses used in the construction industry.

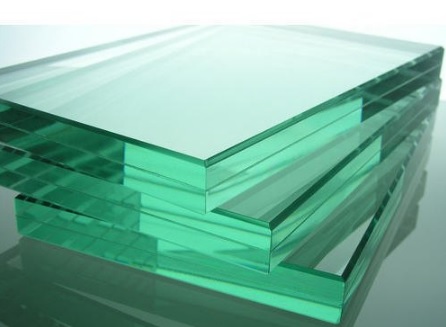

1. Float Glass:

Float glasses are very smooth and distortion-free. These glasses are used for making other glasses like laminated and heat-toughened glasses.

2. Shatterproof Glass:

Shatterproof glass is laminated glass. It is manufactured by bonding two or more sheets of glasses with an invisible interlayer of polyvinyl. It cracks like a spider web.

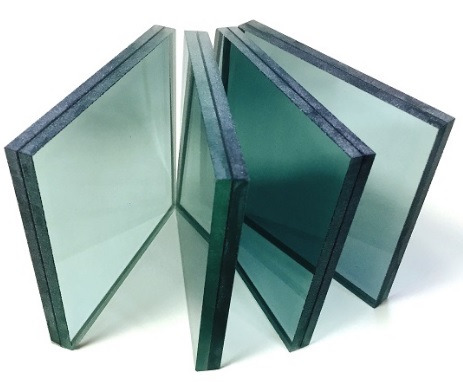

3. Laminated Glass:

Laminated glass is manufactured by using two plies of glass. These glass plies are bonded with each other to create a permanent bond. Even after breaking, it creates a very strong uniformed layer.

4. Extra Clean Glass:

Extra clean glass has two special properties, photocatalytic and hydrophilic. Because of these two characteristics, it works as stain proof and provides a beautiful appearance. Maintenance of extra clean glass is also very easy.

5. Chromatic Glass:

Chromatic Glass is a color vision assistance tool for persons who have difficulty identifying specific color differences between specific color pairs because of a color vision deficiency. Chromatic glass can control daylight and transparency effects.

6. Tinted Glass:

Tinten glasses are colored glasses. Specific ingredients are mixed in the glass to manufacture colored glass. Different ingredients produce different colors. (As shown in the table given below).

| Coloring ion | Color |

| Iron oxide | Green |

| Sulphur | Blue |

| Manganese dioxide | Black |

| Cobalt | Blue |

| Chromium | Dark green |

| Titanium | Yellowish brown |

| Uranium | yellow |

7. Toughened Glass:

It is a very strong glass. This type of glass has very low visibility. It forms tiny granular chunks after breaking.

8. Glass Blocks:

Glass block fabricated by using two different halves. These halves are pressed and annealed together at the time of melting.

9. Annealed Glass:

Annealed glass is manufactured with zero internal stress in the glass. It is produced by heat treatment, i.e., rapid cooling, or by toughening or heat strengthening.

In this process, glass is heated above the transition point then permit to cool gradually without being quenched.

10. Heat Strengthen Glass:

Heat-strengthened glass has been subjected to a heating and cooling cycle and is normally two times as strong as annealed glass of the same thickness and characteristics.