Structural steel can be classified in two ways.

- Based on material composition

- Based on Shape

Table of Contents

Types Of Structural Steel Depending On Material Composition

1. Carbon Steel:

Carbon steel is a strong alloy made by combining iron and carbon. Depending on the percentage of carbon, it can be classified as low, medium, or high carbon steel. The advantage of carbon steel lies in its high tensile strength and cost-effectiveness. Buildings made of carbon steel can withstand natural disasters like earthquakes and tornadoes due to its excellent shock resistance. Additionally, it is environmentally friendly as it can be easily recycled. Its malleable nature allows it to be shaped into various forms, making it suitable for structural members like beams, bridges, reinforcement bars, and highway plates.

2. Stainless Steel:

Stainless steel is another type of alloy comprising iron, carbon, and chromium. The presence of chromium provides corrosion-resistant properties, forming a thin protective layer of Chromium Oxide on the surface. This makes stainless steel ideal for environments that require high hygiene standards, such as kitchens, hospitals, and the food industry. Its bright and shiny appearance also adds to the aesthetics of buildings. Stainless steel is a low-maintenance material that can endure the test of time, making it a popular choice in construction.

3. High Strength Low Alloy Steel (HSLA):

As the name suggests, HSLA steel is designed to meet high strength requirements. Its production focuses on mechanical properties rather than chemical composition. Compared to other steels with similar strength, HSLA is relatively lighter, making it cost-effective. One of its notable advantages is its formability and ductility, allowing it to take various shapes and bends without developing cracks. HSLA’s resistance to corrosion and high temperatures makes it suitable for use in the automotive industry, oil refineries, and other demanding applications.

4. Forged Steel:

Forged steel is a specialized form of steel created by applying high-pressure conditions to a combination of iron and carbon. This process results in a compact and extremely hard material with minimal voids. Due to its tight-grained structure, forged steel efficiently resists impacts, making it perfect for heavy machinery and hydraulic press equipment. It also exhibits excellent thermal stability and can be cast into desired shapes at high temperatures, providing versatility for different applications.

5. Quenched and Tempered Alloy Steel:

This type of steel undergoes a specific heat treatment process called quenching and tempering. In quenching, the steel is heated above its recrystallization temperature and rapidly cooled, resulting in a stronger crystalline structure. The subsequent tempering process further improves its ductility while maintaining its strength. Quenched and tempered alloy steel is widely used in construction, automotive, mining, and heavy mechanical equipment.

You Might Also Like: Built Up Steel Sections

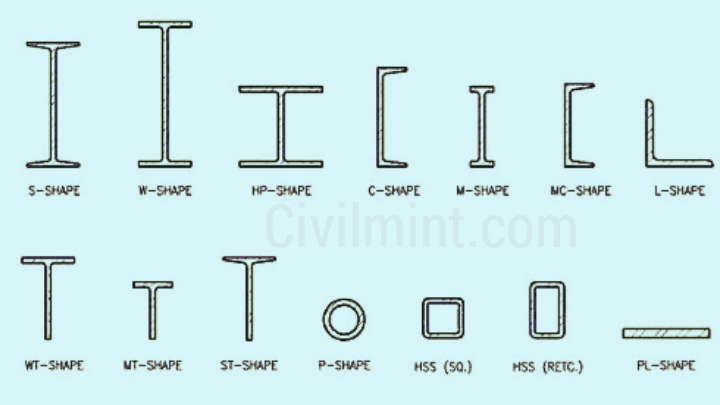

Types Of Structural Steel Depending On Shape

Various international standards provide specifications for the sizes of structural steels. These standards define angles, tolerances, dimensions and cross-sectional measurements of steels, which are then given specific names. The diagram below shows the commonly used structural sizes of steels. While some sections are made through hot or cold rolling processes, others are made by welding flat or bent plates together.