Table of Contents

Introduction Of Septic Tank

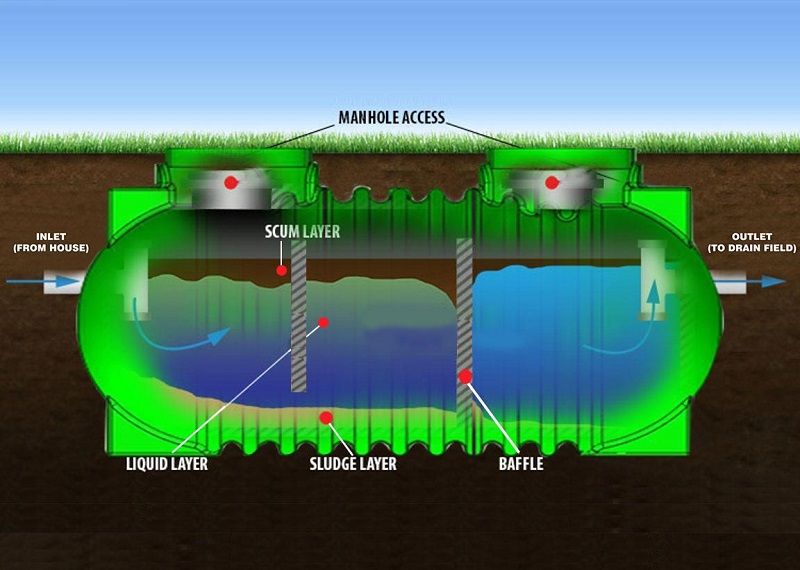

A septic tank can be described as a primary sedimentation tank with a large detention time (12 to 36 hours against a period of 2 hours in an ordinary sedimentation tank).

In un-sewered rural and urban areas, septic tanks are appropriate for the disposal of night soil. But sufficient water must be available as water is required for the flow of the night soil from the latrine to the septic tank and for the proper functioning of the septic tank.

Working Concept

The size of the septic tank is designed in a way that the sewage is retained in the tank for 24 hrs during which certain biologic decomposition by the action of anaerobic bacteria takes place which liquefies and breaks the night soil leaving a small quantity of soil which is known as sludge and settles at the bottom of the tank and clear water known as effluent flows out of the tank.

The waste material from the septic tank is usually disposed of by absorption in the soil through a soak pit if there is no municipal drainage system in the area. If a municipal drainage line exists in the area, the effluent is released to the drain.

It is to be noted that disinfection agents such as bleaching powder, phenyl, etc should not be utilized in cleaning latrines as disinfectant entering the septic tank kills the bacteria growth as a result of which rate of biological decomposition is slow.

Design of Septic Tank

The capacity of a septic tank relies on the number of users and interval of sludge discharge. Generally, sludge should be released every after 2 years. The liquid capacity of the tank is taken as 130 liters to 70 liters per head. For the smaller number of users, 130ltr per head is taken.

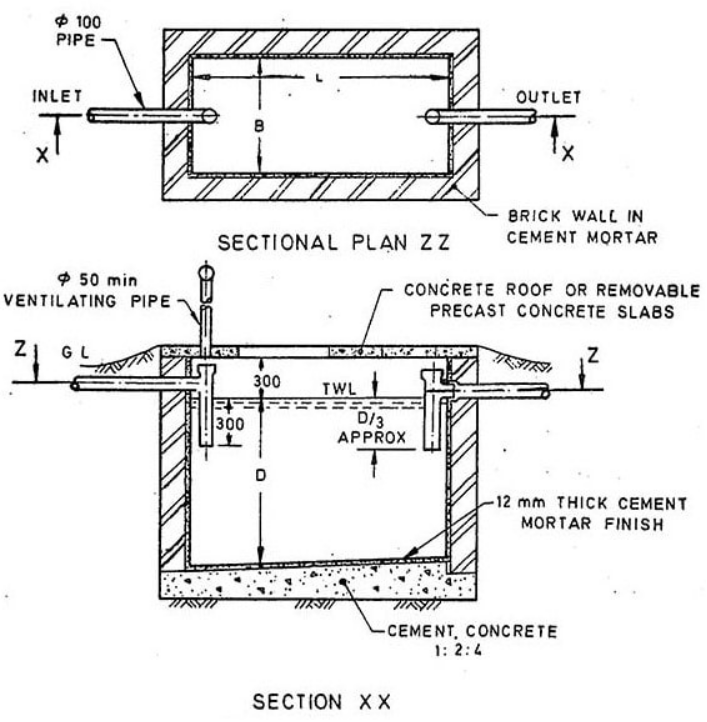

A septic tank is normally provided with a brick wall in which cement mortar [not less than 20cm (9 inches)] thick and the foundation floor is of cement concrete 1:2:4. Inside and outside faces of the wall and top of the floor are plastered with a minimum thickness of 12mm thick cement mortar 1:3 mix.

Inside corners of the septic tank are rounded. Waterproofing agent like Impermo, Cem-seal, Accoproof, etc is added to the mortar at the rate of 2% of the cement weight. A waterproofing agent is to be added in the same proportion into the concrete also for making the floor of the septic tank.

For the right convenience in collection and removal of the sludge, the floor of the tank is given a slope of 1:10 to 1:20 towards the inlet. It means that floor of the outlet side will be on a higher elevation than the floor on the inlet side.

Dimensions of Septic Tank Components

i) Length, Width, and Depth of Septic Tank

Width = 750 mm (min)

Length = 2 to 4 times of width

Depth = 1000 to 1300 mm. (min below water level) + 300 to 450 mm freeboard

Maximum depth = 1800mm + 450 mm freeboard

Capacity = 1 cum (10 cubic feet) minimum

ii) Detention period

24 hrs is considered as a Detention period in septic tank design. The rate of flow of effluent should be equal to the rate of flow of influent.

iii) Inlet and outlet pipes

An elbow or T pipe of 100 mm dia. is submerged to a depth of 270-600 mm below the liquid level. For outlet pipe, an elbow or T type of 100 mm diameter pipe is submerged to a depth of 220-500 mm below the liquid level. Stoneware or asbestos pipes are used.

iv) Baffle Walls of Septic Tank

For small Septic tanks, RCC hanging type scum baffle walls are provided in septic tanks. Baffle walls are provided near the inlet pipe. A baffle wall is optional near the outlet.

The inlet baffle wall is situated at a distance of L/5 from the wall, where L is the length of the wall. The baffle wall is usually extended 150 mm above to scum level and 400-700 mm below it.

Scum being light generally floats at the water level in the septic tank. The thickness of the wall varies from 50 mm to 100 mm for large tanks lower portion are having holes for the flow of sludge.

v) Roofing Slab of Septic Tank

The top of the septic tank is covered by an RCC slab of the thickness of 80-100 mm depending upon the size of the tank. Circular manholes of 500 mm clear diameter are provided for inspection and desludging. In the case of rectangular opening clear size is kept as 600X450 mm.

vi) Ventilation Pipe

For outlet of foul gases and ventilation function cast iron or asbestos pipe of 50-100 mm diameter are used which should extend 2 m (min) above ground level. The top of the ventilation pipe is stipulated with a mosquito-proof wire mess or cowl.

Sectional plan ZZ shows the typical layout of the septic tank. Section XX shows the Cross-Sectional detail of the septic tank

Example – Design of Septic Tank for 30 Users

Liquid capacity of the tank:

@120 Litres per user = 0.12 X 30 = 3.6 cum

Take liquid depth as 1.3 meters.

Therefore Floor area of the tank = 3.6/1.3 = 2.77 m2

Taking length as 2.5 times the width

L X B= 2.77

2.5B X B = 2.77

B = Sqrt(2.77/2.5) = 1.05 say 1 meter

Hence, the dimension of the septic tank is 2.5 X 1 m

Various Types Of Septic Tanks

I have described all the types of septic tanks based on material.

1. Concrete septic tanks:

These are the most common type of septic tank and are made of reinforced concrete. They are highly durable, and their strength can withstand the weight of the soil and the pressure of the groundwater. They are also resistant to corrosion and rust, making them long-lasting.

2. Plastic septic tanks:

These tanks are made of high-density polyethylene (HDPE) plastic, which makes them lightweight and easy to transport and install. They are also resistant to corrosion and rust, making them a good choice for areas with acidic soil.

3. Fiberglass septic tanks:

These tanks are made of a combination of fiberglass and resin, making them lightweight and easy to transport and install. They are also highly resistant to corrosion and rust, making them a good choice for areas with acidic soil.

4. Steel septic tanks:

These tanks are made of steel, which makes them highly durable and resistant to damage from impact or heavy loads. They are also resistant to corrosion and rust, making them a good choice for areas with acidic soil. However, they require a protective coating to prevent rusting.

5. Brick septic tanks:

These tanks are made of bricks and mortar and are commonly used in areas where bricks are readily available. They are durable, but they are prone to cracking and leaking if the mortar is not applied correctly.

6. Wood septic tanks:

These tanks are made of wood and are typically lined with a waterproof membrane to prevent leakage. However, they are not as durable as other types of septic tanks and are prone to rotting and decay over time.