Wood veneer is very popular building material for interior and exterior design of the building. In this article, we will discuss all the important things related to veneer.

Let’s take a deep dive into the article.

Table of Contents

What is Wood Veneer?

Wood veneer is an engineered wood. Its like a thin slice of timber. It is normally mounted on a fiber boards. It is cut into slices thinner than 1/8 inch. The underlying layer of wood veneer is called the substrate. Veneer wood gives the interior panel a perfect wood look.

The purpose of the veneer is to create an interior panel with a high quality solid wood appearance. It is available at moderate cost with low manufacturing times. The veneer wood is stylishly stained to look like real wood.

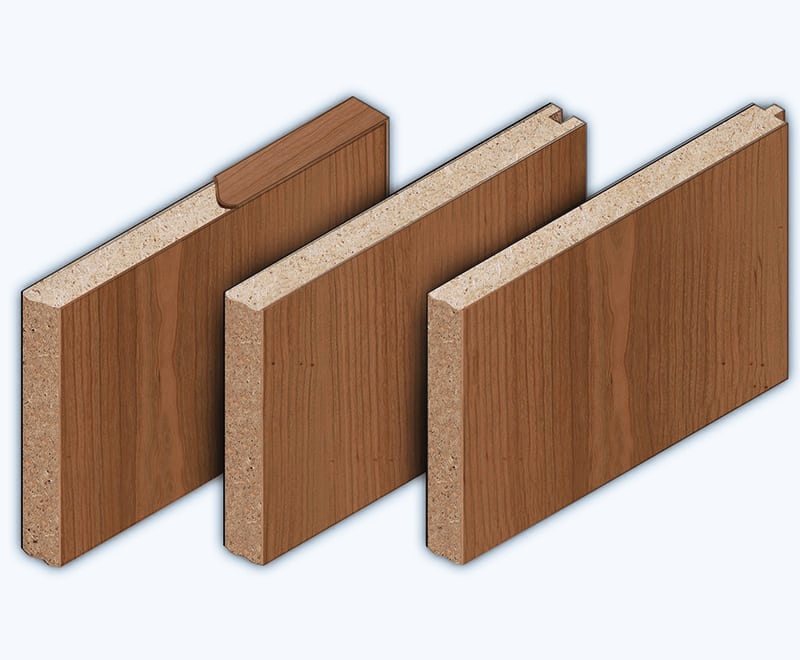

Veneer is actually a “paper-thin” cut of wood that is applied to both sides of a strong core surface, such as furniture grade MDF or substrate material, to seal and stabilize it. This can be interior, furniture or wooden items.

In woodworking, veneer reference to a thin slice of wood and sometimes bark, usually thinner than 3 mm usually a core board such as wood, plywood, or medium density fibreboard. It is used for panels for doors, cover boards, panels for cabinets, parquet floors, furniture parts, etc. They are also used for parquet. Plywood consists of three or more layers of veneer. Each is usually joined at right angles to adjacent layers with grains for reinforcement.

A veneer molding is a thin layer of decorative edging applied around an object such as a jewelry box. Veneer is also used in place of decorative paper for wood veneer high pressure laminate.

Wood Veneer Sheets

Wood veneer sheets are thin boards used to add an elegant finish to various types of furniture such as beds, cabinets and wall panels. Veneer sheets of various wood species such as mahogany, oak, black cherry, maple, bamboo and ash are usually glued to relatively inexpensive substrates such as MDF, plywood and blockboard.

Wood veneer sheets are very durable, elegant yet gentle bag surface that needs to make an impression.

Wood Veneer Rolls

A veneer roll is a finger-jointed strip of real wood veneer. By finger-jointing the veneer strips, you get veneer rolls of infinite length. Equipped with a thickness of 0.25 mm to 0.8 mm as standard.

All composite veneers are fleece laminated. This makes stripwood veneer flexible and durable. After that, a veneer roll with a custom-made width is produced with a vertical slit.

Manufacture of veneer doors, veneer furniture, baseboards and mouldings. Veneer rolls make all surface decorations with the look and feel of solid wood. But cheaper than solid wood panels.

It can be used on laminated aluminum panels and tubes as well as frames and cornices. They use different veneer rolls for interior design and carpentry.

Wood Veneer Panels

Wood veneer panels consists of a core board with two natural or reconstructed veneer faces. It is genuine wood using noble wood carefully selected by experts based on craftsmanship.

Manufacturing Process of Wood Veneer

The finest and rarest logs are sent to companies that manufacture veneers. The best trunks give the carpenter more usable wood than he does from a single tree. The veneer is cut as thin as 0.6mm, with very little wasted wood. Slices of veneer are always kept in the order they were cut from the log and are often sold as such.

Veneer logs are used to make veneer. It’s like a delicatessen worker slicing cheese from a block into thin slices: the log suspends between the two blocks. A long, thin piece of wood for veneer is gradually shaved with a lathe. The substrate then receives this veneer.

Advantages of Plywood

- If the wood is in poor condition, a veneer coating can be applied.

- It extends the life of defective wood.

- Wood veneer offers high durability and strength.

- Fibreboards such as MDF and HDF are easily damaged when in contact with water. Wood covered with veneer. This makes it robust and resilient. It also helps prevent breakage. Wooden veneer furniture is resistant to warping and chipping.

- Plywood is a recyclable and eco-friendly material.

- Once the wood has reached the end of its useful life, it can be shredded. Used as wood waste in the manufacture of MDF and chipboard.

- Wood coating allows for more efficient use.

- Thin veneer is used for the manufacture of furniture.

- Very few pieces of furniture can be made from veneer.

- Mass production of veneer panels is possible. It can be used as veneer material for various furniture.

- Plywood furniture is cheap and environmentally friendly.

- Wood veneers are less prone to warping and cracking than solid wood constructions.

Disadvantages of Plywood

- Liquids can easily penetrate the wood if the plywood is not treated with a surface abrasive. A veneer is attached to a fiberboard that is lighter than a natural wood panel.

- Wood veneers can be more expensive than solid wood or difficult to put back together if damaged.

- Each tree has its own unique texture. This gives each veneer an unmistakable individual look.

- Wood veneer furniture is a great alternative to achieve unique designs.