Table of Contents

Introduction:

XRF stands for X-Ray Fluorescence Spectroscopy. It is one of the best methods to determine the chemical composition of the alloys. This method provides every detail you need to know regarding the components of the alloys which you are using for various purposes. It tells us what percentage of each component is present in the alloy. With this knowledge, we can determine the various properties of the alloy like its strength, toughness, hardness, etc.

Finding out the components by which an alloy has been formed is very important. This can help in avoiding any fraud activities. The various grades of the alloys also depend on the chemical composition. If we change the percentage of the chemical components from which alloy has been made, then its grade will also change. So, in simple words, we can say that the grades of the alloys are determined by the percentage of each chemical component present in the alloys. Together these chemical components determined the overall properties of the alloy.

PMI – Positive Material Identification:

PMI – Positive Material Identification is referred to as a process in which we identify the correct grade of alloy for a specific purpose. It is very important to choose the right grade of alloy for the right place. Otherwise, it will lead to the failure of alloy which can cause accidents.

For example – A bridge is supposed to be made up of from ‘X’ grade of alloy which has the property of acid corrosion resistance. But due to some mistakes, the bridge is constructed by using a ‘Y’ grade of alloy which do not have acid corrosion resistance. So, this kind of mistake will lead to the failure of the bridge and will cause accidents. That’s why PMI is a very important step. It helps us in choosing the right grade of alloy for the right work. So that the failures and the accidents can be avoided.

X-Ray Fluorescence Spectroscopy (XRF) Working Principal:

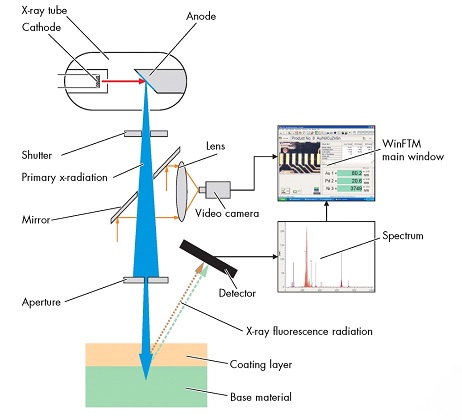

XRF for identifying the chemical composition of the alloys uses low energy x-ray. These low-energy x-ray scan the sample to find out its compositions. When these x-ray strike, it excites the atoms in the sample. These Primary X – rays sent by XRF reflect backs after exiting the atoms in the sample. The reflected X-ray is called the secondary X-ray. These secondary X -rays were then detected by the XRF. According to the detected wavelength of the secondary X- rays, XRF determines the chemical composition of the sample.

XRF Advantages:

- XRF uses a light unit that’s why it is easy to use.

- The sample surface doesn’t need special attention to use in XRF detection.

- Even the small size of the sample can be used such a small piece of wire.

XRF Disadvantages:

- The depth up to which it can measure the sample is very less.

- Not all alloy chemical composition can be detected.