A fuel injection system is a mechanical system that supplies the correct amount of fuel to an engine. The fuel injection system consists of a carburetor, a fuel filter, a fuel pump, a fuel line, and a fuel tank. The fuel system must function properly for the proper operation of the vehicle. Therefore, the system must be properly cleaned. This article mainly describes the mechanism, types, parts, and functions of fuel injection systems.

Table of Contents

Brief Description of Fuel System

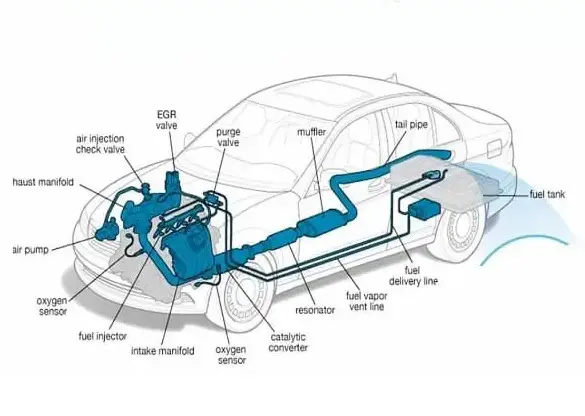

The fuel system is the part of the car that draws fuel from the fuel tank and supplies it to the engine. This system is responsible for supplying fuel as per engine requirements. All parts of the fuel system must function in a proper way to obtain the desired engine performance. The primary or key function of the fuel system is to remove fuel from the storage tank and send it to the combustion chamber of the engine, where it mixes with air to vaporize and burn to generate mechanical power.

The fuel system comprises injectors, pumps, filters, fuel tanks, and carburetors. The proper functioning of all these parts is very important to get the desired performance from the vehicle. The fuel tank is used to store either gas, diesel, or gasoline fuel. When the engine needs fuel, the fuel pump draws fuel from the fuel tank, flows through the fuel line, and transfers it to the carburetor. The carburetor takes in air from the environment and creates an air-fuel mixture. While the air-fuel mixture is being prepared, fuel is supplied to the combustion chamber, where the combustion process takes place.

How Does Fuel Injection System Work?

The fuel injection system is the part of the vehicle that is responsible for supplying the appropriate fuel to the engine. The fuel system works like this:

- First, a fuel pump draws fuel from the fuel tank and passes it through the fuel filter. This filter removes debris from the fuel. It prevents fuel injectors, fuel lines, and carburetors from clogging.

- When the fuel is filtered, the fuel is delivered to the fuel injectors through the fuel lines. Durable plastic or metal materials are used to fabricate the fuel lines. These lines are under the floor of the vehicle and appear to be in vulnerable places. They install in an area that cannot be damaged by engine emissions, weather, road conditions, or other components. Fuel injector operation varies by engine design. In the case of a diesel engine, the fuel injectors inject fuel directly into the combustion chamber.

- However, in the case of the SI engine, the injectors first inject fuel into the carburetor, which first creates a fuel-air mixture and then delivers the mixture to the combustion chamber. The pressure regulator is used to control the fuel pressure from the fuel injectors.

- When fuel enters the carburetor, the carburetor takes air from the surroundings, mixes the air with the fuel, and creates an air-fuel mixture.

- When the air-fuel mixture is created as required by the engine, it is delivered to the combustion chamber. The combustion chamber compresses the air-fuel mixture, igniting the mixture and generating mechanical energy.

Types of Fuel Injection System

- Single-Point Fuel Injection System

- Multi-Point Fuel Injection System

- Sequential Port Fuel Injection System (SPFI System)

- Direct Fuel Injection System

Let’s have a look at these types of fuel injection systems.

1. Single-Point Fuel Injection System

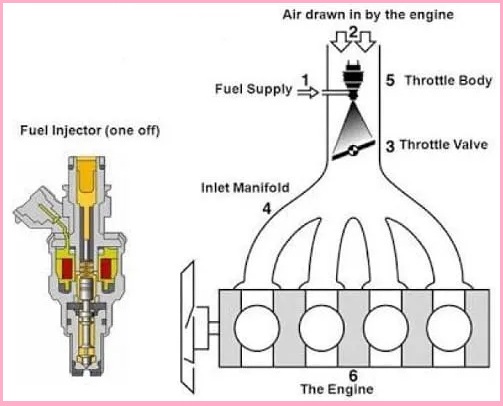

Single point fuel injection systems are one of the most well-known types of fuel injection systems. Also referred to as the throttle body fuel injection system. In this system, the carburetor replaces up to two fuel injectors on the throttle body. For starters, the throttle body acts as the starting point for the car’s engine ventilation system, as well as the starting point for the intake manifold.

Prior to the advent of multipoint injection systems, throttle body injection systems were an excellent alternative to simple carburetors. These are not as accurate as multipoint injection systems, but they offer superior efficiency compared to carburetors. In addition, the single-point fuel injection system requires little maintenance and repair. It has a simpler design than the multi-point injection system. Lower maintenance and repair costs. The main drawback of this system is that it is less efficient and accurate than a multipoint unit.

2. Multi-Point Fuel Injection System

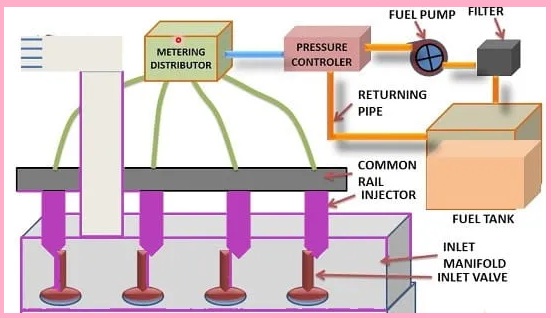

It is the most common type of fuel injection system. We provide a separate injection nozzle for each cylinder. This type of fuel injection system is mounted on the outside of each air intake. Therefore, it is also known as a port injection system. The access of the fuel vapor to the air intake completely draws the fuel vapor into the cylinder, improving the efficiency of the combustion process.

One of the key benefits of a multipoint fuel injection system is the ability to adjust fuel more efficiently than single-point fuel injection or carburetors. In addition, this system reduces the possibility of fuel shortage in the intake manifold. This system is more accurate than the single-point injection system.

3. Sequential Port Fuel Injection System (SPFI System)

The SPFI system is also known as a timed fuel injection system or a sequential fuel injection system. The main difference between sequential injection and multi-point injection systems is that in the case of multi-point injection, all the injectors inject the fuel at the same time. This means that when the engine is idling, fuel typically sits in a port for more than 148 milliseconds. It may not seem like a long time, but in fact, it is a sufficient amount of time to reduce the effect.

Whereas in the case of the SPFI system not all injectors inject fuel simultaneously and each injector injects fuel according to respective cylinder requirements. These injectors inject fuel just before the intake valve opens. This means the fuel doesn’t have to sit for long. As a result, the system increases efficiency and reduces emissions. One of the key benefits of a sequential injection system is that it is more accurate than a multipoint injection system. It also increases the performance of the engine.

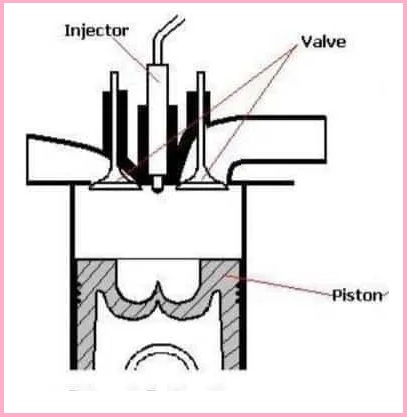

4. Direct Fuel Injection System

It is one of the simplest and most innovative types of injection systems. This system injects fuel directly into the combustion chamber after the valve opens.

The direct fuel injection system is most commonly used in diesel engines but has recently become more popular in gasoline engines as well. For example, Hyundai Venue’s 1.0-liter turbocharged petrol engine uses a direct-injection system sold as the “GDI.” In this configuration, fuel preparation and injection timing are superior to other injection systems.

Components of Fuel Injection System

- Fuel Tank

- Fuel Pump

- Fuel Injector

- Carburetor

- Fuel Filter

- Fuel Lines

- Fuel Gauge

- Fuel Gauge Sending Unit

- Emission Vapor Controls

- Fuel Pressure Regulator

See the below image to visualize it better.

Advantages of Good Fuel Injection System

- Improves engine and vehicle performance.

- Prevents engine damage.

- The fuel injection system extends the life of the engine.

- Increase the efficiency of the engine.

- It provides better fuel efficiency.

Disadvantages of Bad Fuel Injection System

- Fuel injection systems have many components such as fuel tanks, fuel pumps, fuel lines, and fuel injection equipment. Therefore, this system increases the weight of the vehicle.

- The parts of this system are expensive.

- The cost of repairs and maintenance will be high.