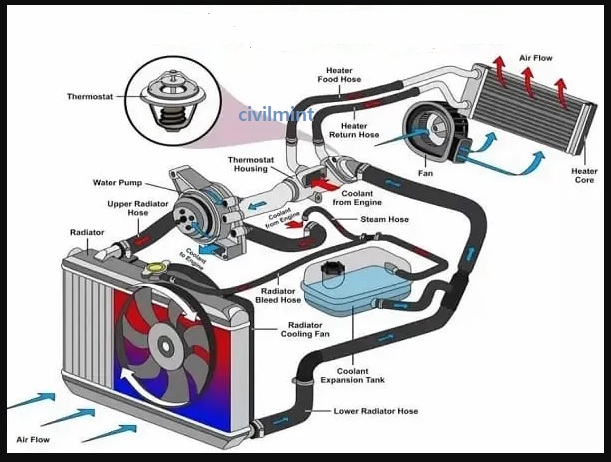

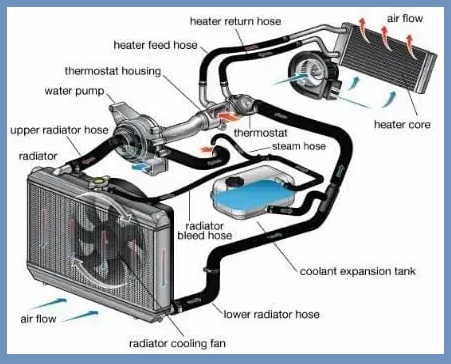

An engine cooling system is a series of different parts that allow liquid coolant to flow through the engine block and cylinder head ducts and absorb combustion heat.

When the coolant absorbs heat, its temperature rises. This hot coolant is returned to the radiator via a rubber hose for cooling. When the heated coolant enters the radiator through a thin tube, it is cooled by the airflow.

This is an important component of an internal combustion engine that prevents the engine from overheating. The cooling system cools the engine and stabilizes the temperature to meet the operating requirements of the engine. The main function of the

engine cooling system is to keep the engine temperature normal and prevent overheating.

The engine cooling system cools the engine by circulating coolant (a mixture of water and antifreeze) through the engine port. Some vehicles use an air circulation system to cool the engine. In this method, air flows through the ribbed cylinder housing.

Overheating of the engine can damage the engine or cause it to stop completely. This heat is generated by the combustion of the air-fuel mixture in the combustion chamber. When the combustion process is complete, the engine temperature will be very high. The cooling system extracts this engine through a heat transfer process.

The cooling system works effectively by removing excess heat from the internal combustion engine and helping to keep the engine at normal operating temperature.

Table of Contents

Working Principle of Engine Cooling System

When the engine is running, it produces extreme heat. This heat is generated by the combustion of the air-fuel mixture in the combustion chamber of an internal combustion engine. A cooling system is used to control the heat of the engine.

There are several water outlets in the engine block along with the engine cylinder. These vents allow the coolant to circulate in the engine head, dissipate the heat of the engine and allow the coolant to flow optimally out of the engine. The rubber hose connects the inlet and outlet of the water pump to the engine.

The cooling system works as follows:

- When the engine warms up, the cooling system starts working. The water pump pumps coolant to the engine’s water outlet.

- When the coolant begins to circulate in the water jet, it absorbs heat from the engine and lowers its temperature to normal operating temperature.

- When the coolant temperature reaches 160 to 190 degrees Fahrenheit, the coolant expands and opens the thermostat’s paraffin wax. The thermostat acts as a valve that opens and closes the coolant.

- When the thermostat’s paraffin wax opens, the coolant flows through the hose and into the radiator. The cooler acts as a heat exchanger. Once the

- coolant enters the radiator, the radiator fan blows cold air from the radiator fins to help cool the coolant temperature quickly. When the coolant cools, it is returned to the water pump. The water pump pumps it back into the water outlet and the entire process is repeated.

- The cooling system`s heat-absorbing capability varies according to the type of engine.

Key Components of Engine Cooling System

- Water pump

- Radiator

- Radiator overflow tank

- Thermostat

- Hoses

- Coolant temperature sensor

- Radiator cooling fan

- Freeze plugs

- Manifold gasket and head gasket

- Heater core

I have also attached the image file for better understanding.

Engine Cooling Systems Types

- Air-cooling system

- Liquid-cooling system

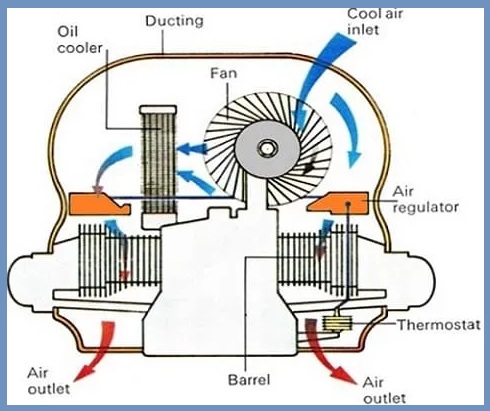

1. Air Cooling System

In an air-cooled engine, the cooling system blows cold air instead of coolant to cool the engine. These types of cooling systems are commonly found on traditional motorcycles and automobiles.

The air-cooled engine uses aluminum fins to cover the engine block. These fins also extract heat from the engine cylinder. A powerful fan pumps air into these fins and transfers the heat of the engine to the circulating air to cool the engine.

The cylinders of these engines are more efficient than the cylinders of water-cooled engines. They can withstand more temperatures than water-cooled cylinders.

The air cooling system has the great advantage of preventing corrosion damage to the cooling system and preventing the coolant from freezing and boiling at extreme temperatures.

However, the temperature control of an air-cooled engine is very complicated, and if the fixed operating temperature rises sharply, high temperature-resistant ceramic parts are required.

In an air cooling system, the amount of heat extracted from the engine depends on the temperature of the cooling air, the temperature of the fins, the speed of cooling air, and the total area of the fins.

These types of engine cooling systems are mainly used in low-power engines such as small air car engines, small cars, scooters, and motorcycles, which provide sufficient speed to cool the engine by the forward movement of the machine. It is also used in compact industrial engines.

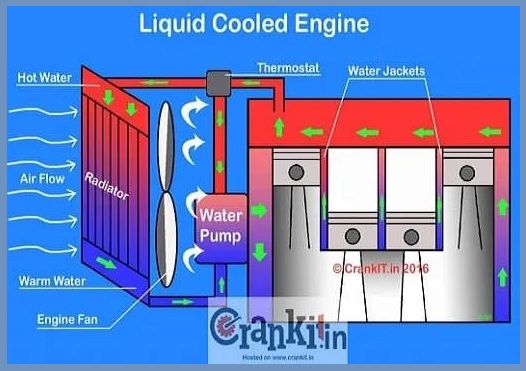

2. Liquid Cooling System

Liquid cooling systems are also known as indirect cooling systems. This system uses liquid coolant instead of air to cool the engine.

In this cooling system, the actual cooling material (that is, air) does not cool the system directly. The air cools the water and water cool the engine.

This system uses a water jacket to enclose the engine. A water pump uses to circulate the water in these jackets.

As the water flows through the water jackets, it extracts engine heat through the heat transfer process. As the engine heat transfers to the water, it heats up. This hot water moves into the radiator. The radiator has a fan that blows cold air and cools the water. This cold water is pumped back into the water jacket and the entire cycle is repeated.

These cooling systems are commonly used in large engines such as trucks, buses, tractors, and automobiles.

Requirement of Engine Cooling System

While the engine is running, the temperature inside the engine can reach 2,500 ° C, which is higher than the melting point of the engine parts. This high temperature can melt or damage engine parts. Therefore, it is necessary to use a cooling system to remove the maximum heat from the engine.

Large amounts of heat can cause thermal stress in the motor. Therefore, the cooling system needs to lower the engine temperature, which reduces thermal stress.

The moving parts of the engine must be properly lubricated. The lubrication system reduces friction on moving parts and ensures the proper functioning of the engine. However, the high temperature of the engine can change the lubrication characteristics. Changes in lubrication characteristics can affect moving parts of the engine. Therefore, to stop this, you need to use the engine cooling system.

The higher the temperature, the lower the volumetric efficiency of the engine. Under certain conditions, the cooling fins can vibrate and increase noise levels. When the temperature rises, the performance of the engine deteriorates.