Table of Contents

What is Plasma Arc Welding?

Plasma arc welding is a liquid state welding process in which a metal-to-metal bond is formed in the molten state.

Hot ionized gases are known as plasmas. These hot ionized gases are used to heat the countertops and compounds are formed by melting.

This welding process is the same as the TIG welding process, except that plasma is used instead of arc to weld the workpieces. This type of weld may or may not use a filler metal.

A major advantage of plasma arc welding is that it uses less power to produce the same heat compared to TIG or MIG welding processes.

Welding Concept

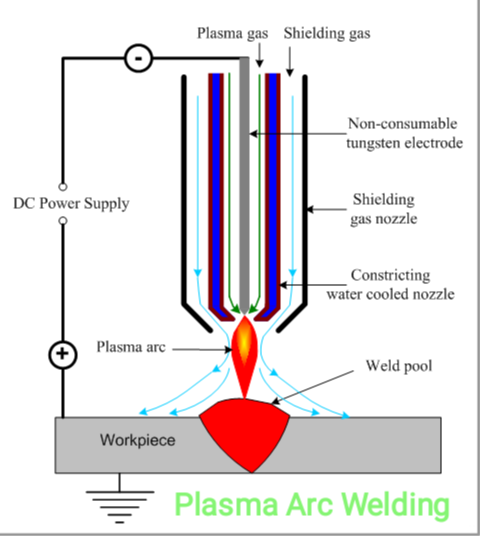

Plasma arc welding is an arc in which coalescence is produced by heat generated by the build-up of a contracting arc between a tungsten alloy electrode and a water-cooled nozzle. This welding process uses two inert gases. One forms the arc plasma and the other shields the arc plasma. A filler may or may not be added.

Working Principal

Plasma arc welding is an modified and improved version of tig welding. TIG welding uses open arc shielded by argon or helium, whereas plasma uses a special torch where the nozzle is used to constrict the arc while the shielding gas is separately supplied by the torch.

The arc is constricted with the help of a water-cooled small diameter nozzle which squeezes the arc, increases its pressure, temperature and heat intensely and thus improves arc stability, arc shape and heat transfer characteristics.

Plasma arcs are formed using gas in two forms; laminar and turbulent.

The gases used are argon, helium, hydrogen or a mixture of these. Plasma welding uses laminar flow to keep molten metal from blowing out of the weld.

A non-transferred arc is used in plasma welding to start the welding process. An arc is created between the electrode (-) and a water-cooled constricting nozzle (+). A non-conducting arc is ignited by using a high frequency unit in the circuit. After the initial high frequency start, a low current is used to form a pilot arc (low current) between the electrodes. After ignition of the main arc, the nozzle is neutral. A continuous pilot arc can optionally be generated for micro-plasma welding grids. The transition arc has high energy density and plasma jet velocity. It can be used for cutting and melting metals, depending on the current and gas flow used.

The Micro Plasma uses currents from 0.1 to 10 Amps and is used for foils, bellows and thin sheet metal. This is an autogenous process and typically does not use filler wires or powders.

Medium Plasma uses 10 to 100 amps current for welding thick plates with up to 6mm filler wire or oxy-fuel plates, and special torches and powder feeders with metal powders Used for metal deposition.

High current plasma over 100 Amps is used for cored wire welding at high travel speeds.

Final Thought

The main advantage of plasma welding is the control and quality of the welded parts. The torch design provides better arc control and more torch standoff tolerance. Welds tend to be clean and smooth when using plasma arc welding.