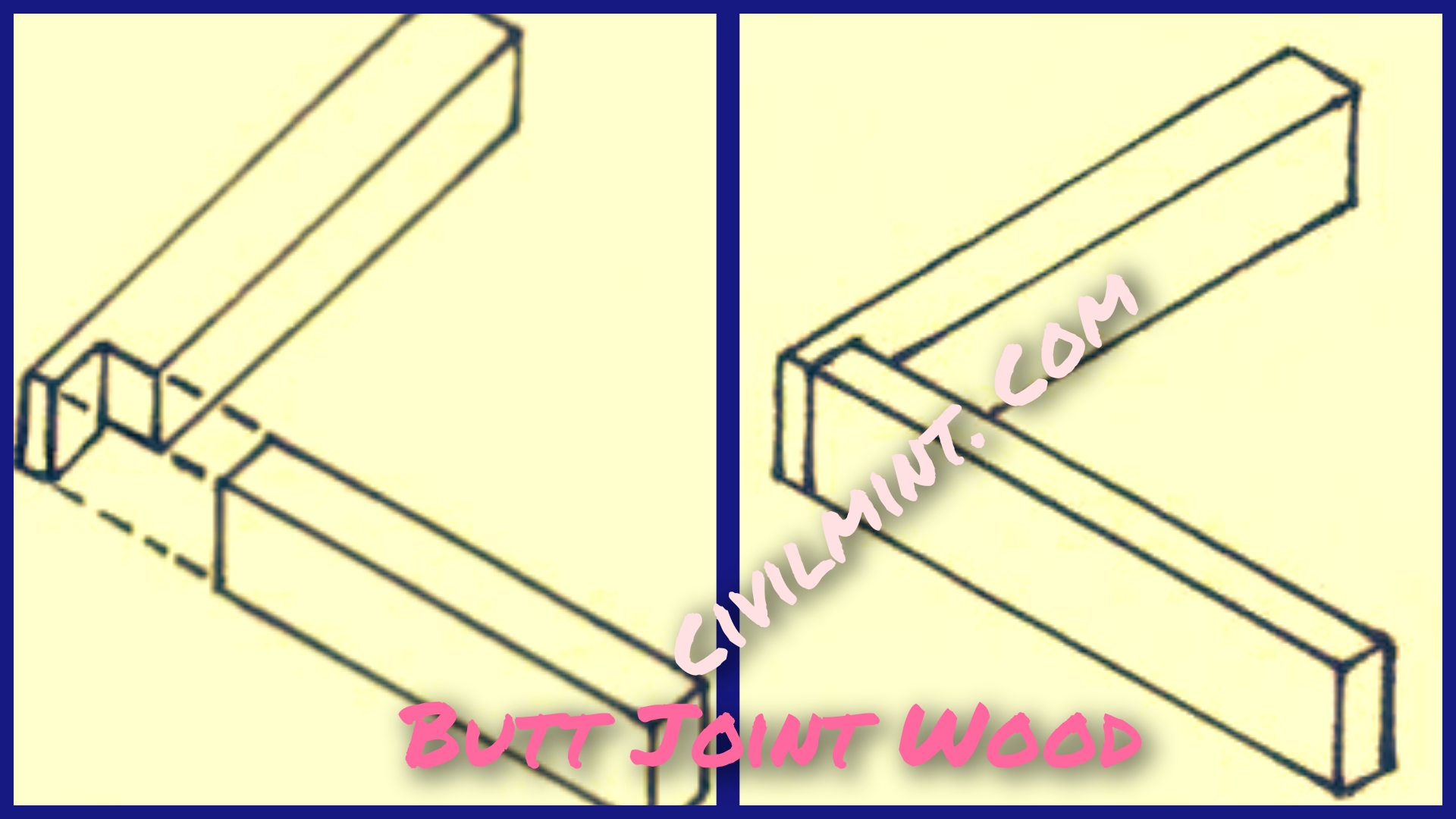

Butt Joint Wood or Wooden Butt Joint is the simplest joint made by joining two pieces of wood at a 90 degree angle.

Table of Contents

What Is Butt Joint Wood?

A butt joint is a simple woodworking joint used to join two pieces of wood at a corner, usually at a 90-degree angle.

This technique involves gluing the end of one board to another and using nails, screws, or other fasteners to hold the joint together. Adding glue between boards can improve the strength of the joint.

However, basic butt joints are not very strong on their own, as they rely on the end grain of the wood, which does not bond well with glue or hold fasteners securely.

To increase the strength of a butt joint, wood gussets or metal brackets may be added for reinforcement. Other techniques, such as biscuit joints, dowels, pocket holes or lap joints, may also be used to strengthen the butt joint.

Despite its limitations, the butt joint is a common and useful technique in woodworking, especially for simple projects where strength and durability are not as important.

It is often used to make picture frames, boxes, and shelves, as well as to join together parts of large projects where the joint will not be subjected to significant stress or tension.

How To Make Wooden Butt Joints?

A butt joint is a basic woodworking joint where two pieces of wood are connected perpendicular to each other.

Wooden butt joints are commonly used in a variety of woodworking projects such as frames, boxes, and cabinets.

Here are the steps to make a basic wooden butt joint:

- Cut the members to the required length: The members to be joined must be cut to the required length using a crosscut saw or a circular saw. One of the members should be cut shorter by the thickness of the adjacent member.

- Align the members: Once the members are cut to the correct length, align them together so that the end grain of one member is perpendicular to the side of the other.

- Secure the joint: Apply glue along the joint and clamp the members together until the glue sets. To prevent the joint from slipping while clamping, you can use a brad nail or a small screw to hold the joint in place.

For enclosed constructions such as four-sided frames or boxes, the thickness of the adjacent members must be taken into consideration. For example, if you are constructing a four-sided box from 19 mm thick material that is to be of finished size 600 mm x 600 mm, two of the members will be docked at 600 mm and two will be docked at 600 mm – 19 mm – 19 mm = 562 mm.

If you want to reinforce the joint, there are additional steps you can take:

For a carcase butt joint, you can add dowels or biscuits to the joint for added strength. You will need a doweling jig or a biscuit joiner to create the holes for the dowels or biscuits.

For a frame butt joint, you can use a miter saw or a table saw with a miter gauge, crosscut sled, or sliding table attachment to create a mitered joint. This will add more glue surface area to the joint, making it stronger.

Summing Up

Butt joint wood is a simple and basic woodworking joint that is easy to manufacture. It is commonly used in a variety of woodworking projects and can be reinforced for added strength.

Article reference: This article is produced after consultation with woodworking industry experts.

Fact Checked by CivilMint Team