The rabbet joint is a widely used woodworking joint for connecting two pieces of wood in cabinet making. A dado blade is used to create a rabbet joint.

Table of Contents

What Is A Rabbet Joint?

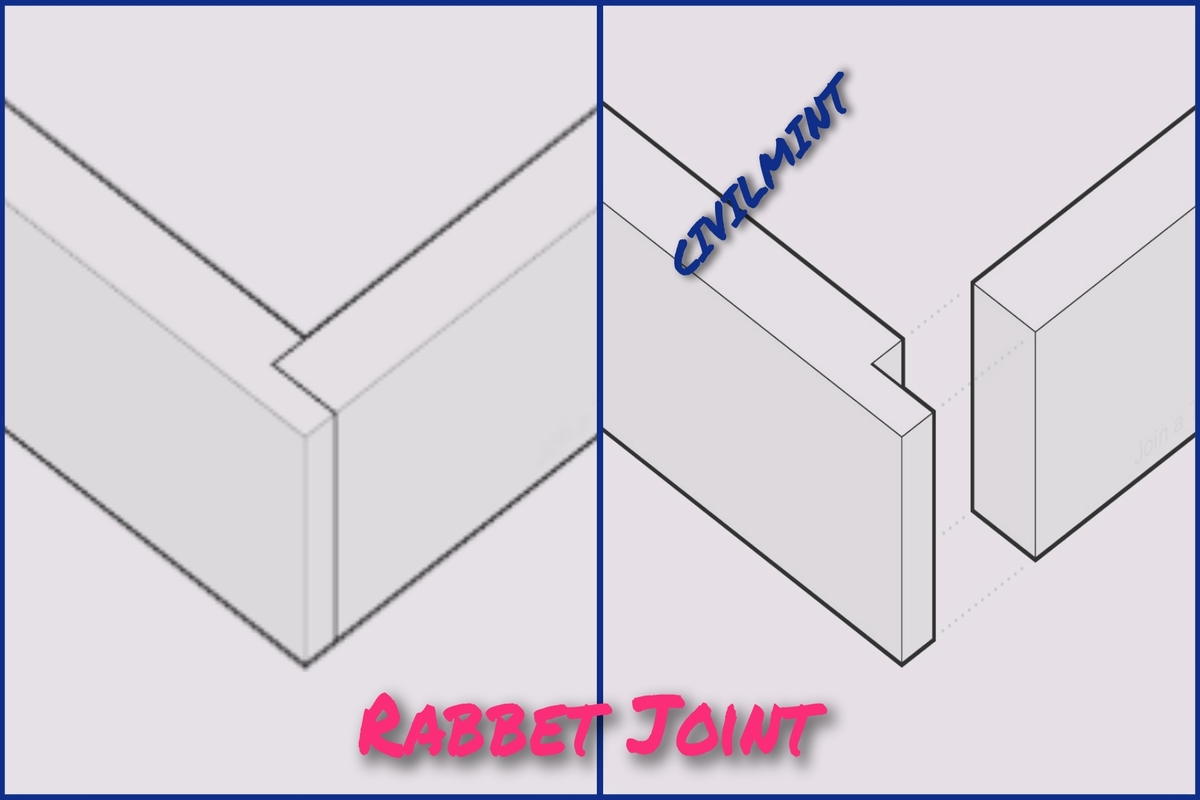

A rabbet joint is a carpentry technique that involves cutting a recess in the edge of a workpiece, resulting in a protrusion called a tongue. This joint is commonly used in the construction of shelving and cabinet boxes, as well as lighter items such as picture frames and drawers.

Rabbet joints are typically cut with a table saw, table-mounted router, or hand-held router using a rabbet or straight bit. Compared to a simple butt joint, a rabbet joint provides a stronger mechanical connection due to the increased surface area where the wood can be glued.

A double rabbet joint, where rabbets are cut into both sides of adjacent workpieces, creates an even stronger joint.

In carpentry, the dado is another type of joint that is commonly used and can be joined with rabbets to form a rabbet and dado joint. A dado is a three-way channel cut into a workpiece that receives another piece of cut material to fit snugly inside the channel to form a dado joint.

Joining a rabbet with a dado cut creates a joint that is stronger and more rigid than a standard through dado cut. While the rabbet joint is great for lighter items, dado joints are preferred for heavy-duty projects like cabinets and shelving, because of the way the three-way channel connects to the adjoining piece of wood and Provides even more surface area, resulting in a sturdier finished project. ,

When choosing a joint for your project, consider where the item will be installed and whether it will need to hold heavy or light items, as this will affect both the finished look and the strength of the joint.

Pros:

- It is strong and durable.

- Easy to construct.

- Conceals end grain.

- Increases glue surface area.

- Provides a flush surface for attaching hardware or other components.

- Can be used for both decorative and functional purposes.

- Reduces the amount of wood needed for a project.

- Resists warping and twisting.

- Helps to align pieces during assembly.

- Can be used with a variety of woodworking tools and techniques.

Cons:

- Limited joint flexibility

- Can weaken the strength of the wood by removing material

- Requires precision and accuracy during cutting and fitting

- May not be suitable for certain types of wood or projects

- May be more difficult to disassemble or modify than other joint types.

Uees Of Rabbet Joint

Rabbet joints are a popular method for joining two pieces of lumber together in woodworking projects. This involves cutting a groove or channel (rabbit) into one piece of wood and then fitting the other piece into the groove, resulting in a strong and flush joint.

In addition to joining two pieces of wood together, rabbet joints can also form a ledge or lip at the edge of a piece of wood, which can be used to hold books or other objects.

These joints are commonly used in picture frame construction to hold the glass, picture and backing securely in place, creating a professional looking frame. Rabbet joints can also be used to join plywood sheets together for large surface areas in construction projects.

Rabbet joints can add decorative features to woodworking projects by cutting grooves or channels into pieces of wood, which can be used for inlay or beading designs.

yes.

yes, it is highly durable.