In this article, we will talk about What is Gear and Types of Gear.

Table of Contents

What is Gear?

The gears are in a circular shape which rotates accordingly to transmit the torque. In gears, the teeth are carved on them, so they can mesh with other gears that have the same teeth cut in them, to rotate smoothly. We can say that the gears have many functions but these three are the most important ones – It increases the torque level in the driven part. The speed which is produced by motors can be reduced with the help of gears for various reasons. The gear also helps in changing the direction of the shaft. We can connect the gears with various types of equipment with the help of belts, chains, couplings, etc. If power is constant, then the torque and speed of the gears will be inversely proportional to each other.

Now we know What are Gear let’s discuss Types of Gear.

Different Types Of Gears:

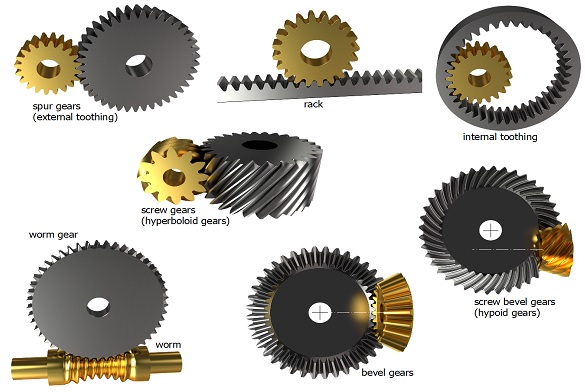

Various types of gears are as follows.

⦁ Spur Gear

⦁ Helical Gear

⦁ Bevel Gear

⦁ Worm Gear

⦁ Hypoid Gear

⦁ Internal Gear

⦁ Spiral Bevel Gear

⦁ Rack And Pinion Gear

Spur Gear:

The spur gear can be used to transfer the power between two parallel shafts only. The spur gear teeth are cut in such a way that it is parallel to the axis of the shaft. It can only produce a radial load reaction. The axial load reaction is not possible with the spur gear. The spur gear teeth mesh very smoothly.

Helical Gear:

The teeth of the helical gear are cut in such a way that it makes a certain angle with the axis of the shaft. Because of these angular teeth cut in helical gear more than one tooth mesh at a time during operations. This allows helical gears to carry more load compared to the spur gear. The helical gear transmits the torque very smoothly.

Bevel Gear:

If we want to transmit the power which has a 90-degree angle with the shaft, then bevel gear is used. The bevel gears are the most commonly used gears to transmit the torque at a 90-degree angle. It is the most expensive gear of all. The bevel gear forms a cone shape to the pitch surface. The teeth of the bevel gear are also cut along the cone.

Worm Gear:

The worm gear is used to transmit the power at right angles when a non-intersecting shaft is present. The worm gear is most useful when the shock load happens. But the efficiency of the worm gear is very low compared to other gears. Because of its lower efficiency, it is only used in low-power applications. It is made up of two parts. The 1st part is a mating gear known as the worm wheel and the 2nd part is a shaft in a screw shape called a worm. The worm is made up of hard material while the worm wheel is made up of soft material to reduce the friction between them.

Hypoid Gear:

Hypoid gear is very much the same as the spiral bevel gear, but the only difference is that it is used when the shaft does not intersect. Hypoid gears are arranged in such a way that the pinion lies on a different plane than the gear itself. Because of this arrangement, the shafts required bearings on both ends to support them.

Spiral Bevel Gear:

The spiral bevel gear is the bevel gears in which the teeth are cut in a curved line. The spiral bevel gears provide higher efficiency, but it creates more vibration and noise when operating.

Internal Gear:

In Internal gear, the teeth are cut inside the cone or cylindrical part. This can be used to mesh with the external gears. This kind of gear is used in planetary gear drives and shaft couplings.

Rack and Pinion Gear:

The rack and pinion gear convert the rotational motion into linear motion. It is made up of two parts. The first one is a circular part called the pinion and the second part is a linear gear called a rack. So, when the pinion rotates on the rack it converts the rotational motion into the linear motion.

That brings an end to our guide on “What is Gear and Types of Gear”.