In this process, the material is taken out by the effects of a very high-speed stream gas abrasive mixture focused on the workpiece.

The high-Velocity effect of a rough molecule causes a little fragile break on the work surface and the streaming gases divert the removed little workpiece molecule.

Table of Contents

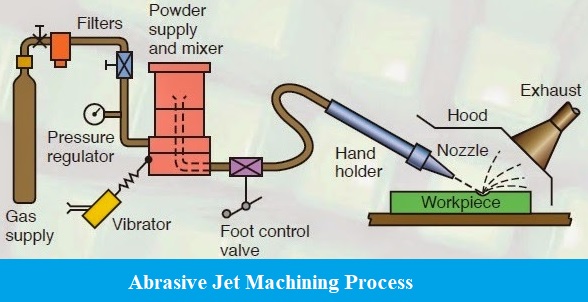

Process of Abrasive Jet Machining (AJM)

Abrasive-jet machining procedure is very much similar to traditional sandblasting but differs in the way that the abrasive is much finer and the process parameters are effectively controlled.

Material is taken out by fine rough particles, normally, around 0.001 in (0.025 mm) in diameter across, driven by a high-speed liquid stream; normal gases are air or inactive gases such as nitrogen. Pressures for the gas range from 25 to 130 psig (170-900 kPa or 4 bars) and velocities can be just about as high as 300 m/s (1,000 km/h).

Equipment Description

Abrasive Jet machines are normally independent bench-top units. In the first place, it packs the gas and afterward blends it in with the abrasive in a mixing chamber. The gas goes through a united dissimilar spout prior to entering the blending chamber and afterward exits through a focalized spout. The spout can be handheld or mounted in an installation for programmed tasks.

Spouts should be profoundly impervious to the scraped areas and are commonly made of tungsten carbide or engineered sapphire. For normal material expulsion, tungsten carbide spouts have a valuable existence of 12 to 30 hours, and sapphire spouts last around 400 hours. The distance of the spout from the workpiece influences the size of the machined region and the pace of material expulsion.

Feature of Abrasive-jet Machining:

- The size of the abrasive particles varies from 10 to 50 micrometers.

- The system of material expulsion is because of brittle fracture by impinging grating grains rapidly.

- This process is appropriate when the material is brittle and weak.

- The number of grains per unit time is 2 to 20 g/minutes.

- The pressure of air/gas normally kept between 2 to 10 MPa.

- The nozzle is made by WC with an orifice area of 0.05 to 0.2 mm2 and its life is 12 to 300 hours.

Advantages:

- The process is very flexible.

- It produces very low heat.

- The machine has the ability to work with brittle materials.