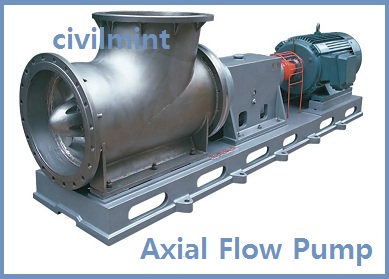

An axial flow pump is a kind of dynamic pump that sucks in parallel to the direction of the impeller. Axial flow pumps do not change the direction of fluid flow. In an axial flow pump, fluid enters and exits the pump parallel to the impeller. There is an impeller inside the tube. This pump has 3-4 blades attached to the impeller.

The pump blades are designed so that the pump sends water parallel to the axis rather than perpendicular to the impeller. Due to the parallel arrangement of the impeller blades, very low pressure is generated when pumping water. These pumps are used in high flow, low-pressure applications.

These dynamic pumps can produce high flow rates of up to hundreds of thousands of gallons per minute. Sometimes referred to as a propeller pump due to the fact the axial impeller resembles a ship’s propeller. In some configurations, the flow rate and head may be adjusted by changing the pitch of the impeller blades.

The functional specifications of the axial flow pump are slightly different from the functional specifications of other types of pumps. The head produced at a normal duty point is minimal, but the head and capacitance curves are much more vertical than other dynamic pumps. At the very best efficiency, the shutoff pressure can be three times that of the pump head. In addition, the specified energy will increase as the flow rate decreases, and the maximum power consumption is when the power is turned off. This is in contrast to the same tendency for centrifugal pumps, which require higher flow rates and higher powers.

Table of Contents

How Does Axial Flow Pump Work?

In axial pumps, impeller blades guide the fluid axially. In this pump, pressure is generated by directing the liquid to the impeller blades. In these dynamic pumps, the impeller blades have an airfoil that allows fluid to flow and generate pressure.

The liquid is pushed out towards the axis of rotation of the impeller. That is, the fluid particles do not change their radial position as they flow through the pump. As a result, the liquid can flow axially into the impeller and exit the liquid almost axially. The propellers of these dynamic pumps are driven by electric motors.

The required power increases as the flow rate decreases and the maximum power are obtained at zero flow rate. Radial centrifugal pumps, on the other hand, reverse this function and require more power as the supply capacity increases. Power requirements and pump heads also increase with tilt, adapting the pump to system conditions for the most efficient operation.

Compared to traditional centrifugal pumps or centrifugal pumps, axial flow pumps can pump up to 3 times more liquid with a pressure head of fewer than 4 meters. By changing the propeller pitch, these dynamic pumps can be easily adjusted to operate at maximum efficiency at high pressure or low pressure and low pressure / high pressure.

Axial flow pumps generally have a lower head than centrifugal pumps but can produce higher flow rates. Axial flow pumps can only produce heads of 10 to 20 feet. This is less than other types of centrifugal pumps.

Applications and Uses of Axial Flow Pump

- These dynamic pumps are widely used in various industries around the world.

- These pumps are used to treat wastewater from the fisheries, agriculture, municipalities, and businesses.

- Use of axial flow pumps in fermenters and power plants to circulate liquids.

- This type of dynamic pump is used for low head and high flow applications.

- They are used in the chemical industry to circulate the liquid in the evaporator.

- On sailboats, these are used to transport the pumps used to sail the ballast.

Pros

- The fundamental gain of the axial flow pump is that the head is relatively low and the flow rate is relatively high.

- These dynamic pumps are best for high flow rates and low heads.

- With an axial flow pump, the effects of fluid rotation are less severe.

- Axial flow pumps are easy to set up for low flow and high lifts for very efficient operation. Of the many traditional pumps, these pumps are the smallest.

- Due to its small size, it is easy to use and handle.

Cons

- These pumps are expensive.

- These pumps have no control over viscous liquids.

- These are not optimal for applications that require high heads.