Table of Contents

Buttress Dam Definition

A buttress dam is a structure that has a solid, impenetrable upstream face, supported at regular intervals on the downstream side by a series of buttresses or supports. These buttresses are typically made of reinforced concrete and are designed to be heavy, allowing them to push the dam into the ground. The design of the dam can take the form of a straight or curved wall. The water pressure exerted against the dam is counteracted by the inflexibility of the buttresses, which prevent the dam from collapsing.

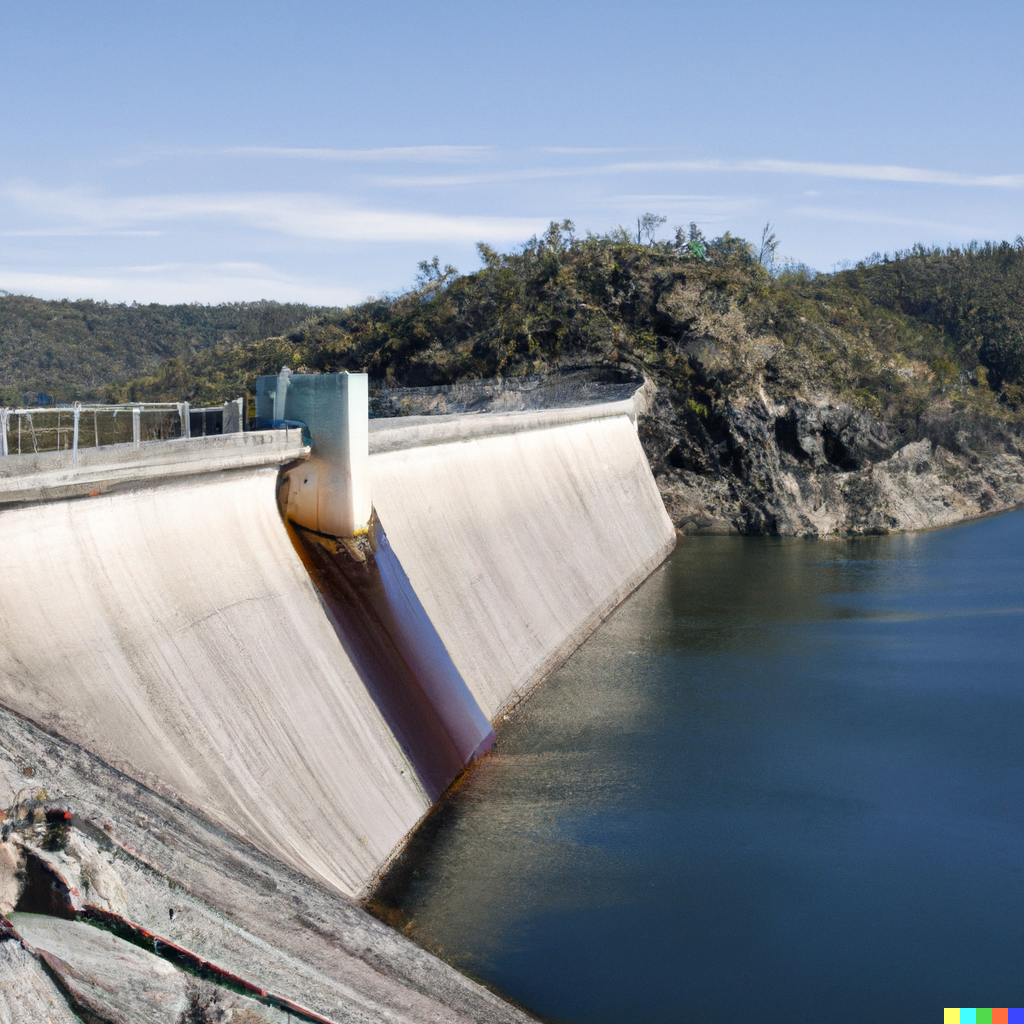

See the image of buttress dam as shown below.

Description

Buttress dam were initially constructed for the purpose of holding water for irrigation in regions where resources were scarce but labor was inexpensive. Buttress dams are an ideal option for wide valleys where solid rock is scarce. With advancements in design, the advantages and disadvantages of buttress dams have become more apparent. The ancient Romans were among the first to utilize buttresses to enhance the stability of a dam wall. During the early 20th century, buttress dams made of slab concrete construction became a popular choice in the United States.

Buttress Dam Design

Designing a buttress dam requires a thorough understanding of the site’s geology, hydrology, and the potential impact of the dam on the surrounding environment. The design must also take into account the dam’s intended purpose, as well as the size and volume of the reservoir it will create.

The following are some of the key factors that must be considered when designing a buttress dam:

- Hydrology: The design must take into account the flow rate and volume of water that the dam will need to hold back. The dam’s spillway and outlet works must also be designed to safely release excess water.

- Geology: The design must take into account the geology of the site, including the soil and rock types, as well as the potential for landslides and other geological hazards.

- Foundation: The foundation of the dam must be able to support the weight of the dam and the water it will hold back. The foundation must also be able to withstand the forces of the water and any seismic activity in the area.

- Materials: The dam must be made from materials that are strong, durable, and able to withstand the forces of the water and any seismic activity in the area. Concrete and masonry are commonly used for buttress dams.

- Spillway and Outlet works: To safely release excess water, a spillway must be included in the design of the dam. An outlet works is also necessary to control the release of water for irrigation or other uses.

- Stability Analysis: In order to ensure the stability of the dam, the design must include a stability analysis that takes into account factors such as the dam’s shape, the materials used, and the water pressure on the dam.

The following formula is used to calculate the stability of a buttress dam:

FOS = W / (Pu x FS)

Where: FOS = Factor of Safety W = Total weight of the dam and the water it will hold back Pu = Ultimate load capacity of the foundation FS = Factor of Safety for the foundation

The Factor of Safety (FOS) is a measure of how much stronger the dam is than it needs to be to withstand the loads it will experience. A factor of safety of 1.5 or greater is considered acceptable for a buttress dam.

Advantages of Buttress Dam:

- A buttress dam is typically smaller in size compared to a gravity dam.

- It can be built on a relatively thin foundation, which is not possible for a gravity dam.

- The upstream face of a buttress dam is designed to withstand wide vertical water pressure, which improves its stability and preservation of concrete.

- The safety factor of a buttress dam is generally higher than that of a gravity dam.

- The dam’s resistance to ice damage is improved as ice slides across the inclined upstream surface.

- The height of a buttress dam can be increased by extending both the buttresses and deck slab.

- Additional structures such as power plants can be built in the open space between the buttresses.

- The cost of building a buttress dam may be higher due to the need for additional formwork and reinforcement.

- The space behind the deck slab can be accessed through the gap between the buttresses for regular inspections and repairs.

- The construction process can be faster as thinner parts do not pose cooling problems.

- The layout of the buttresses can be adjusted to suit the conditions of the foundation.

- Buttress dams can accommodate moderate levels of foundation movement without significant damage, making them suitable for building on soil with differential settlements.

- The amount of concrete required for a buttress dam is typically 1/3 to 1/2 of that needed for a gravity dam of the same height.

- Regular access to the upstream side of the dam and the foundation between the buttresses is possible for inspections, grouting and pressure grouting as needed.

- The uplift pressure on a buttress dam is significantly lower, which improves the economy of concrete and overall stability of the dam.

- Power plants, switchyards, and other structures can be built between the buttresses, reducing construction costs.

Disadvantages of Buttress Dam:

- The thickness of the slab is limited, despite access to the end of the slab via the gap between the buttresses.

- The skilled labor standards and concrete-to-shutter ratio are higher for a buttress dam than for a gravity dam, resulting in a higher unit cost of concrete.

- Damage to the upstream surface of the relatively thin reinforced deck slab or arch of a buttress dam can have a significant impact on the integrity of the dam.

- The volume of water sealing required for a buttress dam is typically higher than for other types of dams.

- The stress on the foundation is greater and a solid rock foundation or spread base or continuous mat may be necessary, which increases construction costs.

- The savings from using less concrete may be offset by the need for strong reinforcing for the relatively thin members of a buttress dam.

- Buttress dams are more vulnerable to intentional destruction than strong gravity dams.

FAQS

Q: What are some examples of buttress dams?

A: Some examples of buttress dams include the Gavins Point Dam on the Missouri River in the United States, the O’Shaughnessy Dam in California’s Hetch Hetchy Valley, and the John W. Keys III Dam on the Columbia River in Washington state. Additionally, the Bonneville Dam, also on the Columbia River, features a combination of both buttress and gravity dam design.