A Centrifugal pump is a mechanical pump that pumps liquid by converting mechanical energy into pressure energy of the liquid flow. This mechanical energy is usually provided by an electric motor or motor. Centrifugal pumps use centrifugal force to pump liquids. Therefore, it is called a centrifugal pump.

This is the most effective form of hydraulic tool used in lots of industries and in lots of ordinary gadgets to transport fluids from regions of low strain to regions of excessive strain. It makes use of an impeller to pump liquid or water from one area to another. In 1475, engineer Francesco Di Giorgio Martini designed a centrifugal pump as a tool for lifting sludge.

The real centrifugal pump become first observed withinside the seventeenth century. Next, Denis Papin designed a straight-blade centrifugal pump. British explorer John Apold invented the curved vane centrifugal pump in 1851. These forms of dynamic pumps are specially used withinside the meals and chemical enterprise to successfully pump viscous liquids. These pumps are less expensive than high-quality displacement pumps. Simply put, it`s a tremendous pump that could paintings successfully in quite a few applications.

Centrifugal pumps are very not unusual to place in industries across the world. The essential motive for his or her recognition is that those pumps do now no longer be afflicted by frictional overall performance degradation. This dynamic pump has an easy layout and could be very clean to control. There aren’t any leaks or warmth switch issues. For this motive, it has precedence over high-quality displacement pumps.

How Does Centrifugal Pump Work?

It states that the operating principle of the centrifugal pump corresponds to the basic principle of angular momentum and that the change in the angular momentum of the rotating element corresponds to the applied force.

When a certain amount of fluid is rotated by an external force (power of an electric motor or turbine), centrifugal force acts on the fluid and further converts the speed of the fluid into pressure. Part of this energy is converted into liquid kinetic energy.

The function of the centrifugal pump is almost the same as that of the centrifugal compressor, but there is only one difference in the hydraulic fluid. Centrifugal pumps work as follows:

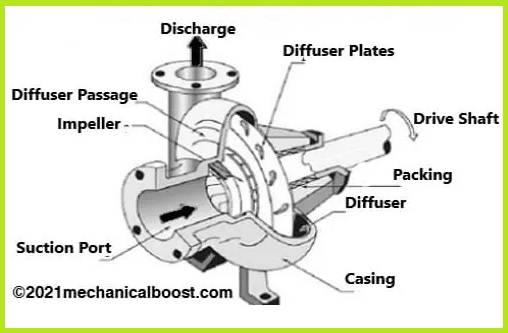

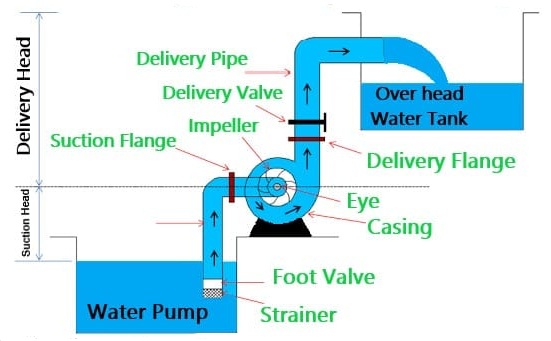

- First, mechanical energy is supplied to the impeller by an electric motor or a heat engine. The propeller is directly connected to the electric motor through a shaft and moves back and forth along with the movement of the motor shaft.

- As the turbine begins to rotate, a vacuum begins to form inside the turbine’s eye.

- Due to this vacuum, water begins to enter the eye in the axial direction. When water gets into the eyes, the water will hit the propellers. The impeller rotates the water radially and axially out using centrifugal force. This wheel continues this movement of water until it passes through all its components.

- Turbine blades convert the kinetic energy of water to its speed and increase the speed of the water.

- After passing through the impeller, the water enters the diffusion area. This diffuser slows down the water by reducing its speed. It converts the speed of the water into pressure energy. After increasing the desired pressure, the water discharges through the pump outlet and transfers into the desired position.

In this way, the centrifugal pump raises the pressure and carries a variety of liquids.

If I talk about it in a more direct way, in a centrifugal pump, the centrifugal force acting on a liquid or water causes the liquid or water to rise to a certain height. Therefore, this pump is known as a centrifugal pump. And this is the complete working principle of centrifugal pumps.

Advantages

- Centrifugal pumps are easy to maintain

- As a piston pump. It takes less space to install.

- The size is small.

- Process large amounts of liquid.

- These pumps are capable of pumping

- Sensitive and dangerous liquid.

- There is no fear of loss due to friction.

- There are no leak issues with this pump.