Table of Contents

Introduction

Today we are going to learn about a very important structural engineering topic “Concrete Cone Failure”. This phenomenon is also called concrete cone breakout. This type of failure usually occurs in RCC structures. Structural elements such as anchor bolts, threaded rods, and other types of fasteners experience this type of failure. When the applied load exceeds the design load, concrete cone failure occurs.

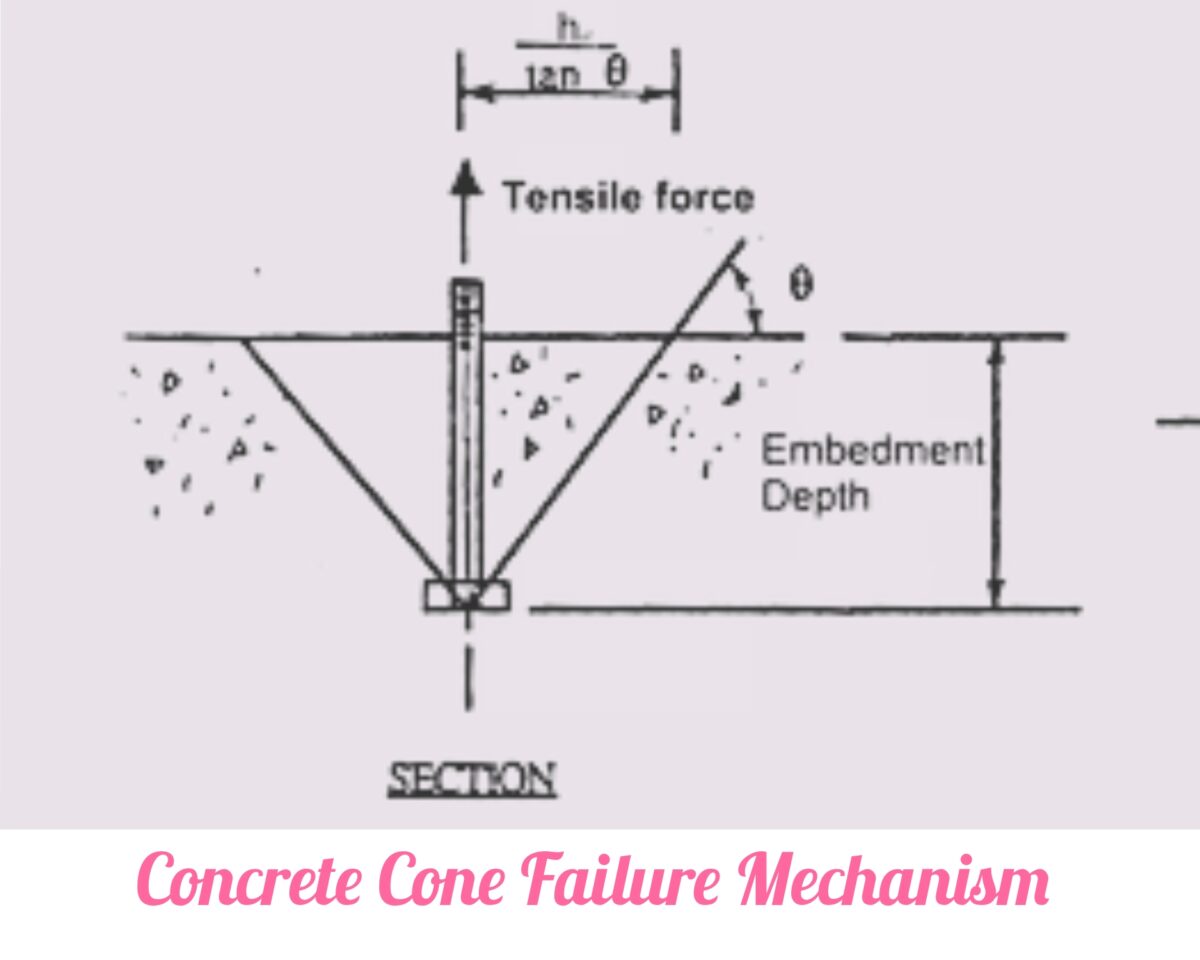

In the below figure, I have shown the mechanism of Concrete Cone Failure.

Learn About How Concrete Cone Failure Occur

Concrete cone failure can occur in many ways. Let’s know all the possible scenarios

1. Fasteners In Concrete Such As Anchor Bolt

In many construction projects, mechanical fasteners like anchor bolts and threaded rods are used to attach structural elements, equipment, or fixtures to concrete surfaces. These fasteners are inserted into pre-drilled holes in the concrete and secured in place using various methods, such as epoxy or expansion.

2. Applied Loads Such As Tensile Load And Shear Load

Once the anchor bolts or fasteners are installed, they experience different types of loads. Tensile loads pull the fastener outward, perpendicular to the surface of the concrete, while shear loads apply forces parallel to the concrete surface.

3. Stress Concentration

Stress Concentration: The loads applied to the fastener get transferred to the surrounding concrete through a localized area called the “concrete cone.” This concrete cone forms around the anchor or fastener due to the pressure exerted on the concrete by the fastener.

4. Failure Mechanism:

Concrete is strong in compression but weak in tension. As the applied loads increase, the stresses at the edges of the concrete cone can reach critical levels, causing the concrete to crack and ultimately fail. This failure mode is referred to as “concrete cone failure” because the concrete around the fastener tends to break and form a cone-shaped fracture surface.

Effects Of Concrete Cone Failure

When concrete cone failure occurs, the anchoring system loses its capacity to hold the applied loads securely. This can compromise the structural integrity of the entire assembly and potentially lead to collapse or instability, depending on the specific application and loads involved.

Learn How To Prevent Concrete Cone Failure

To prevent concrete cone failure, it is crucial to use appropriate fasteners and anchoring systems that are designed to withstand the expected loads.

Engineers and designers should consider factors like concrete strength, embedment depth, edge distance, and the type of mechanical fasteners to ensure a safe and reliable connection between the concrete and the attached elements.

Regular inspections and maintenance are also essential to identify potential issues and address them before they lead to failure.

I also recommend you to read my article on Difference Between Anchor Bolt And Threaded Rod.

Conclusion

Concrete cone failure is very serious issue and can collapse compression members gradually. Design engineers should follow ASCE (American Society of Civil Engineers) recommendations while designing a structure.