Full form of EOLB Permit is Equipment Opening and Line Break Permit.

Table of Contents

What is an EOLB Permit?

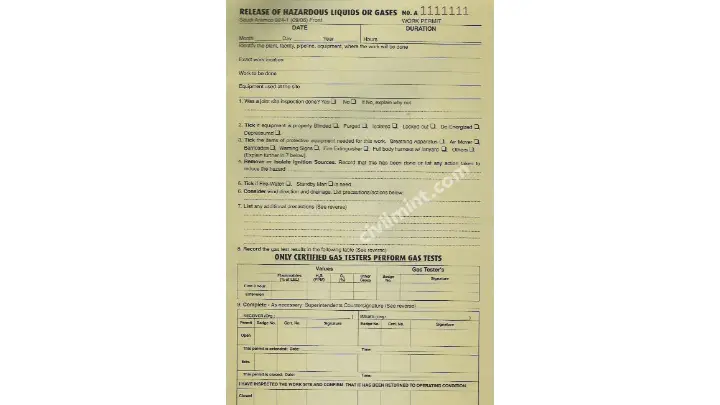

An Equipment Opening/Line Break Permit (EOLB Permit) is a crucial authorization mandated by Saudi Aramco for tasks involving the opening of equipment, vessels, or pipelines within a closed system. This encompasses a range of activities such as maintenance, repairs, equipment installation/removal, inspections, cleaning, decontamination, and purging.

Importance of EOLB Permits

EOLB Permits are pivotal in upholding safety standards and safeguarding workers from potential dangers. Working on equipment within a closed system carries inherent risks, including exposure to hazardous materials, fires, and explosions. EOLB Permits mitigate these risks by compelling contractors to adhere to a set of rigorous safety procedures.

Obtaining an EOLB Permit

Acquiring an EOLB Permit entails submitting an application to the Saudi Aramco permit issuer. This application must comprehensively detail the planned work, associated hazards, and safety precautions. The permit issuer meticulously reviews the application, granting approval if all requirements are met.

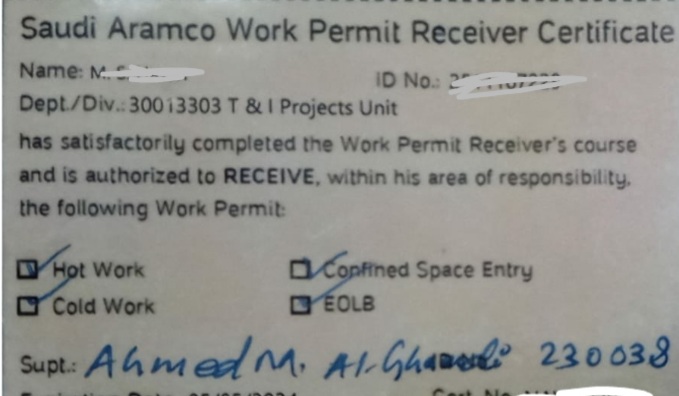

EOLB permits may be issued to authorized permit reciever who are EOLB certified. Most permit recipients typically have 3 permits (hot, cold, and confined space). Therefore the permit issuer must confirm whether the permit reciever has an EOLB permit on his WPR card.

Once approved, the contractor is responsible for strict adherence to safety measures, including equipment isolation, purging, hazardous material checks, and on-site supervision by a qualified individual. After the work’s completion, the contractor must restore the equipment or pipe to its original state and inform the Saudi Aramco permit issuer to close the EOLB Permit.

EOLB Permit Requirements

While specific EOLB Permit requirements vary based on the task and hazards, there are general prerequisites applicable to all EOLB Permits:

- Possession of a valid Saudi Aramco Contractor Safety Management System (SMS) certificate.

- Presence of a qualified on-site supervisor to oversee safety compliance.

- Submission and approval of a permit application before commencing work.

- Proper isolation of the equipment or pipeline.

- Thorough purging and inerting of the system.

- Rigorous testing for hazardous materials.

- Strict adherence to all pertinent safety protocols.

EOLB Permit Safety Precautions

Safety measures associated with EOLB Permits are contingent on the specific task and associated risks, but common precautions include:

- Isolation of equipment or pipelines through the use of valves, blinds, or similar isolation mechanisms.

- Purging and inerting, which involves eliminating oxygen and flammable gases and replacing them with inert gases like nitrogen.

- Testing for hazardous materials using gas detectors, air sampling, or equivalent methods.

- Maintaining a qualified supervisor on-site who is well-versed in the task’s hazards and safety procedures.

EOLB Permit Violations

Non-compliance with EOLB Permit requirements can result in severe consequences, including accidents, injuries, and even fatalities. Contractors breaching EOLB Permit rules may face disciplinary actions, including fines and suspensions.

Conclusion

EOLB Permits constitute a vital facet of Saudi Aramco’s safety management system, assuring the execution of work in a secure environment and safeguarding the well-being of workers. Contractors subject to EOLB Permits must scrupulously adhere to safety protocols and satisfy all permit stipulations.

Read this: How to apply for WPR Aramco Schedue

Additional Information

In addition to the aforementioned details, it’s essential to note that EOLB Permits have a finite validity period. Upon expiration, contractors must secure a new permit before commencing any further work.