Table of Contents

What Is Material Inspection Request?

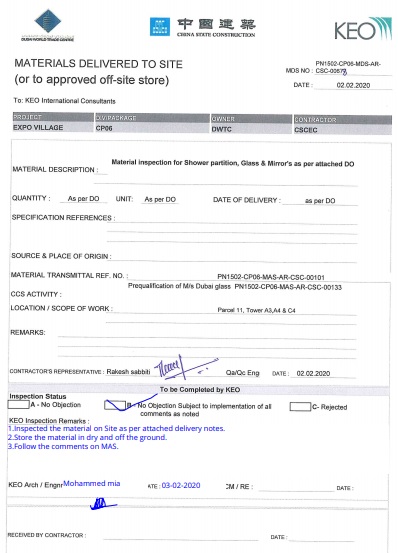

Material Inspection Request(MIR) is a formal way of material submittal to the consultant or client.

Before fabrication on large scale, a sample is submitted to inspect. Normally, The given material is already approved in the shop drawing. If the consultant or client approves MIR then fabrication and execution can be done on-site.

If there is any defect in the material then the consultant rejects it, in this case, the contractor has to submit another MIR with corrective measures.

In big projects, a huge quantity of material is required, so there are possibilities of mismatch. To tackle this problem, the material was inspected every as the contractor delivered on the site.

In smaller projects, there is only a one-time approval process. After that corrective measures are to be taken in the form of a Work Inspection Request (WIR).

Work Inspection Request (WIR) also called Request For Quality Inspection (RFQI).

Advantages Of Material Inspection Request

A material inspection request has several advantages in construction industry. Here are some of the main benefits:

1. Ensuring quality:

Material inspection requests help make sure that the materials used in a project or production process meet the required standards and specifications.

By carefully checking materials before using them, you can identify any problems, inconsistencies, or differences that could affect the quality of the final product.

2. Compliance and safety:

Material inspection requests play a vital role in ensuring that safety regulations and industry standards are followed.

By inspecting materials, you can find potential dangers, such as faulty parts or harmful substances, and take the necessary steps to address them. This helps create a safer working environment.

3. Saving money:

By finding defects or substandard materials early on, material inspection requests can prevent costly rework, repairs, or replacements later.

Catching and dealing with issues early can save time and money, reducing production delays and the risk of product failures.

4. Evaluating suppliers:

Material inspection requests provide an opportunity to assess the performance and reliability of suppliers.

By conducting thorough inspections, you can identify suppliers who consistently provide high-quality materials and remove those who don’t meet the required standards.

This evaluation process helps in making informed decisions when choosing suppliers and building long-term partnerships.

5. Customer satisfaction:

Ensuring the quality of materials through inspections contributes to customer satisfaction. By delivering products or projects that meet or exceed quality expectations, you enhance customer confidence and loyalty.

Satisfied customers are more likely to recommend your products or services and become repeat customers, positively impacting your reputation and business growth.

6. Process improvement:

Material inspection requests provide valuable data and insights that can be used to improve manufacturing or construction processes.

By analyzing inspection results and identifying recurring issues, you can take corrective actions, refine procedures, and optimize workflows.

This continuous improvement cycle can lead to increased efficiency, reduced waste, and improved overall performance.

7. Legal and contractual compliance:

In certain industries, such as construction, material inspection requests may be necessary to meet legal and contractual obligations.

They provide documented evidence of compliance with specific standards, codes, or regulations, which is important for meeting legal requirements, resolving disputes, or obtaining necessary certifications.