Table of Contents

Introduction of Metal Grating or Metal Grate

Metal gratings are very useful perforated metal products widely used in various industries as floors, trench covers, mezzanines, trailer beds, scaffolding, stair treads, fences, grills, bridges, fire escapes and maintenance platforms . They are made by drilling holes in sheet metal or connecting metal rods to a grid. Various manufacturing processes such as expanding, drilling, forming and welding are used to produce metal mesh.

The most common metals used to make metal mesh are iron, carbon steel, aluminum and stainless steel. Metal grates must have sufficient load-bearing capacity and must have a non-slip surface to act as a safe working platform.

Types of Metal Grating

The most popular types of metal grating which is normally used in industrial applications is listed below.

- Expanded Metal Grating

- Bar Metal Grating

- Wire Mesh Metal Grating

- Perforated Metal Grating

- Safety Grating

- Compound Metal Grating

- Press Locked Metal Grating

We will discuss these 7 types of metal grating in detail.

1. Expanded Metal Grating

Expanded metal mesh is made by slitting a metal plate. After making the slit, the metal plate is stretched or pulled to spread it. Because of this diffusion effect, this type of metal mesh is called expanded metal mesh. The grating is created with a rhombic pattern with a non-slip surface. Finished sheets are cut to the size required to meet application requirements. Common metals used to make this type of metal grill are carbon steel, stainless steel, and aluminum.

Efficient and economical production of expanded metal mesh. The structural strength of the seat is good. A standard expanding process is commonly used during manufacturing along with cold rolling to achieve a smooth and uniform surface finish. Expanded metal mesh is widely used in flooring, fencing, security applications, stairs, etc.

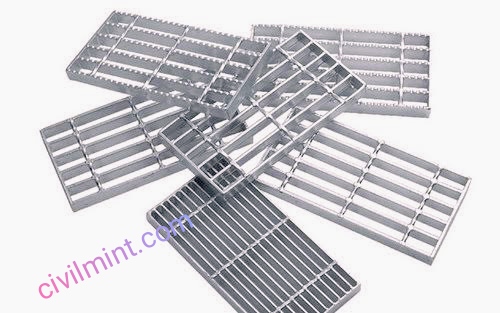

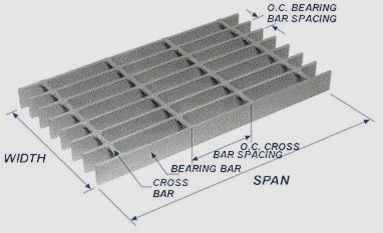

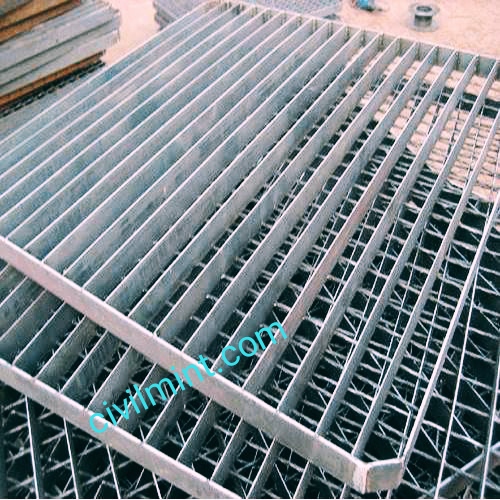

2. Bar Metal Grating

This is the most common type of metal mesh. Bar gratings consist of parallel bars connected to vertical bars by various methods such as welding, riveting, press fitting and tight meshing. The connection method for bar grids is determined based on the thickness of the bars, materials used, and cost.

Steel and aluminum are the most common metals used to manufacture bar gratings. Due to its high strength-to-weight ratio, it is used in industrial floors, road gullies, fire escapes, bridges, etc.

3. Wire Mesh Metal Grating

Wire Mesh Metal mesh is also popular with names such as wire cloth, wire mesh and wire mesh. This type of metal mesh is created using rows and columns of intersecting wires. The popularity of wire mesh grids is due to their ease of installation, high durability, flexibility, and versatility.

Depending on the manufacturer, wire grating can be welded or woven. Welded wire mesh is welded where rows and columns intersect. Wire mesh, on the other hand, is woven like cloth so that the columns and rows of intersecting wires rise and fall at the connection points.

Wire mesh metal mesh is used for separation and filtration, security work, ventilation, shielding and fencing, material reinforcement, etc.

4. Perforated Metal Grating

Perforated metal grids are also called perforated screens, perforated plates, or perforated plates. They are made by stamping, punching, or deforming sheet metal to create holes of specific sizes, patterns, and shapes. Particularly robust metals such as stainless steel, carbon steel and aluminum are used as sheets for this type of metal grid. Holes are created by various metalworking processes such as rotary pinning, stamping, and laser cutting.

Common applications for perforated metal mesh include sound insulation, ventilation, shielding, dry cleaning, centrifugation and building materials development.

5. Safety Grating

Safety gratings, also known as grip strut gratings, provide a firm, solid, non-slip walking surface. These types of metal grids are designed to increase traction and prevent tripping, slipping and falling. Small diamond lugs are commonly used on safety grilles to increase grip and traction. The open surface prevents liquid build-up and aids drainage and air circulation. The improved grip of the safety grating is due to the interlocking edges of the diamond openings created by cold stamping. Steel and aluminum are common materials for security grilles.

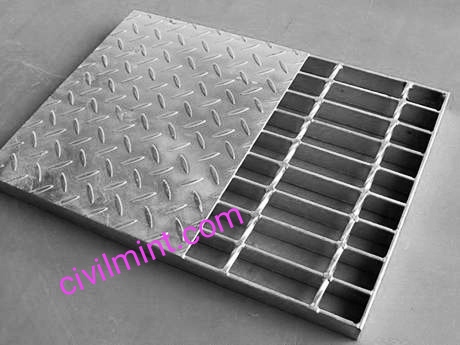

6. Compound Metal Grating

Composite metal grids are a combination of two types of grids, commonly bar grids and steel plate grids. They usually consist of a checkered plate fixed to the surface of a steel bar metal grid using steel plates with a thickness of 3 mm to 6 mm. Composite metal gratings are available in a variety of sizes and material types.

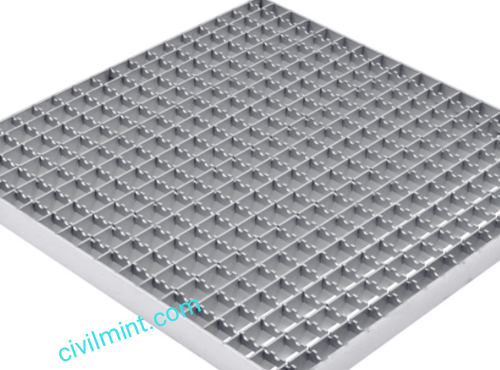

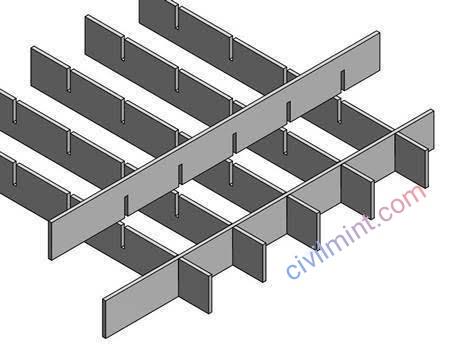

7. Press Locked Metal Grating

In a stamped metal trellis, the crossbars and bearing bars are notched and pressed together, hence the name. They have a smooth, flat surface on top of the connected bar. Metal pressure-locked gratings are aesthetically pleasing, are commonly manufactured from steel and aluminum, and come in a variety of sizes and bar openings.

Common Materials for Making Lattices

Grating usually refers to any type of cover or frame used as a hole cover, protection, support or platform. A variety of materials can be used to manufacture gratings. Stable plastics can also be used to manufacture gratings.

Metal mesh is generally more popular due to its strength and adaptability to many environmental conditions. Specialized metal mesh is used in various industries, airports and manufacturing facilities and is extremely strong and durable. Common materials used to make metal mesh are:

- aluminum

- light steel metal

- stainless steel

- galvanized steel

- high performance carbon

Uses of Metal Grating

- In building services, metal mesh can be used as floors, walkways, platforms and mezzanines to provide safe, strong and durable structures and protective barriers.

- Metal mesh is popular in water filtration systems due to its corrosion resistance and exceptional strength. Easily capture plastic bags, boxes and other types of trash.

- Metal grating is commonly used for floors. In marine and sewage conditions aluminum floor gratings are used. Steel-to-metal floor gratings are typically used for heavy-duty applications.

- Wire mesh is used as a fence because of its beauty, strength, and rigidity.

- Steel bar grating is used to cover pits and sumps where chemicals and water collect.

- Metal grids also find application as loading ramps for loading and unloading heavy loads on elevated platforms and vehicles.

- Bar gratings are commonly used for running boards, brake steps, catwalks and platforms on locomotives, freight cars and rail cars.