Table of Contents

What Is Micropile?

A micropile, also known as a root pile, is a specialized type of deep foundation element used in construction and geotechnical engineering projects to provide structural support and stability in challenging soil conditions or areas with weak or unstable ground.

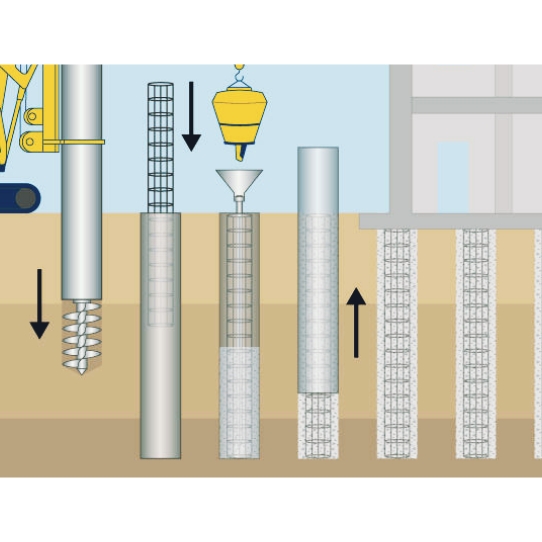

The construction process of a micropile involves drilling a borehole into the ground using methods such as rotary drilling or percussion drilling. The diameter of the micropile typically ranges from 100 to 300 millimeters, which is relatively small compared to other types of piles.

Once the borehole is formed, the construction team injects cement grout under pressure into the hole to fill the voids in the surrounding soil and strengthen the pile. This process, known as grouting, also transfers loads from the micropile to the soil, enhancing its load-bearing capacity.

To reinforce the micropile further, the construction team inserts a steel reinforcement element into the borehole. The choice of the reinforcement element, such as a rebar (a steel bar), a steel tube, or an H-type profile, depends on the design requirements and site conditions. This reinforcement element provides additional strength and stability to the micropile.

The drilling method for creating the borehole depends on various factors. The construction team can use compressed air as a drilling medium to remove the soil cuttings during drilling.

Alternatively, they can employ a supporting drilling fluid, such as water, cement grout, bentonite, or other suitable substances. The drilling fluid helps stabilize the borehole and control the pressure of the surrounding soil.

Micropiles offer several advantages in construction projects. Their small diameter allows them to be installed in areas with limited access or low headroom, where larger piles may not be feasible.

They are also suitable for retrofitting or strengthening existing structures. Micropiles are commonly used to support buildings, bridges, retaining walls, and other structures that require reliable foundation support.

Types Of Micropiles

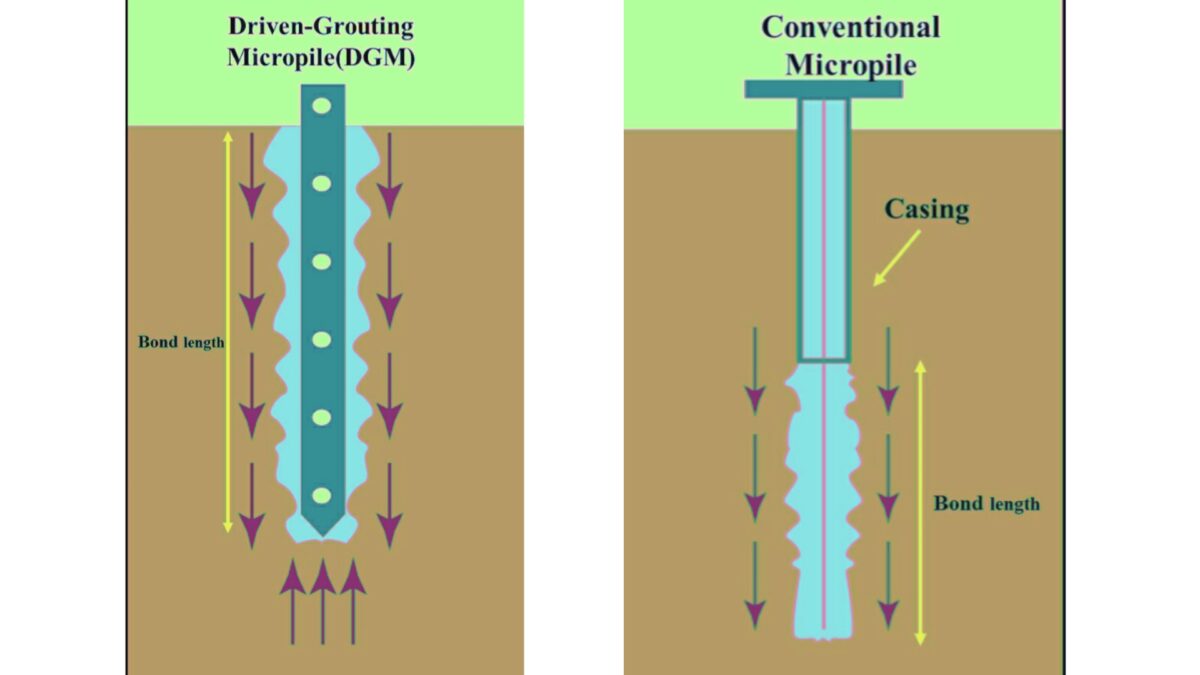

1. Grouted Micropiles:

Grouted micropiles are constructed by drilling a small-diameter hole into the ground and then injecting grout under pressure through the hollow core of the drill rod.

The grout fills the void between the micropile and the surrounding soil, providing both structural support and soil reinforcement.

This type of micropile is commonly used in unstable soil conditions or where high load capacity is required.

2. Driven Micropiles:

Driven micropiles are installed by driving steel or concrete elements into the ground using impact or vibratory hammers.

The driving process displaces the surrounding soil, creating a compacted zone around the micropile.

These micropiles derive their load-bearing capacity from both end-bearing (resistance provided by the bottom tip of the pile in competent soil or rock) and skin friction (resistance generated along the sides of the pile due to soil adhesion).

Driven micropiles are often used in cohesive soils and competent rock formations.

3. Helical Micropiles:

Helical micropiles are constructed by screwing a helical-shaped steel shaft into the ground. The helical plates provide both axial and lateral resistance, allowing them to function as deep foundation elements.

These micropiles are effective in soft soils, expansive clays, and areas with high water tables. They can also be installed with minimal vibration and noise, making them suitable for environmentally sensitive areas.

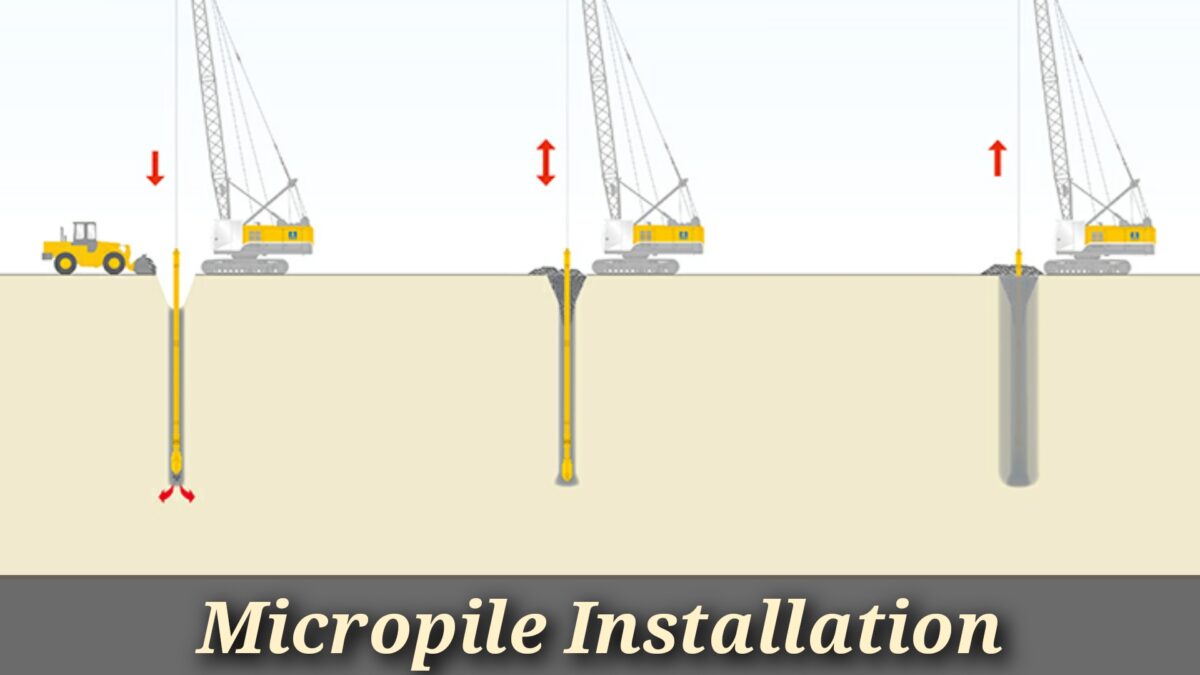

Installation Process Of Micropiles

- Micro-piles are drilled into bedrock and connected to the rock socket wall to bear loads.

- The casings of the mini piles are used during the drilling process into the bedrock.

- After drilling, the drill rod is removed, leaving the steel casing in place.

- Once the desired saturation level is reached, the drilling bit is removed, while the casing remains in the borehole.

- A reinforcement load rod is inserted into the casing.

- Centralizers are used to reinforce and position the load rod within the borehole, along with a mixture of tremie grout and cement water blend.

- Cementitious grout is injected under pressure into the minipile casing and rock socket.

- Pressure grouting is conducted through preinstalled grouting tubes after the tremie grouting process.

- The casings for the mini piles are raised to a higher bedrock level to ensure bonding to the reinforcement bar. Excess steel is trimmed from the top of the mini piles.

Uses Of Micropiles

- Micropiles are used to make structures like buildings and bridges strong and stable.

- Micropiles help fix foundations that have become weak or need extra support. They make sure the buildings stay safe and don’t get damaged.

- Micropiles can carry very heavy loads from the structures to the ground. They make sure the weight is distributed well and everything stays strong.

- Micropiles are used to prevent landslides and soil from sliding down hills. They make the ground stronger and keep it from moving.

- Micropiles support walls that hold back soil or water. They make sure the walls stay strong and don’t fall down.

- Micropiles are great for building in tight spaces where it’s hard to work. They are small and can be put in difficult areas to make sure everything stays safe and strong.

Advantages Of Micropile

- They have a high load-bearing capacity and can withstand compressive, tensile, and lateral forces.

- Micropiles excel at penetrating various surfaces.

- They enhance soil densification at the bottom.

- Micropiles provide increased skin friction.

- Simultaneous drilling and grouting allow for low overhead and limited access operations.

- Micropiles are generally preferred over “H” piles due to overhead physical restrictions.

- Piling rigs can be low-emission or electrically driven.

- They offer calculated total corrosion protection.

- Micropiles are small and lightweight, making them easily manageable.

- They are cheaper compared to other types of piles.

- Limited vibration and noise minimize disturbance.

- Micropiles can be installed near existing walls with limited headroom and space requirements.

Disadvantages Of Micropile

- Micropiles can’t hold as much weight as bigger foundations.

- Micropiles aren’t very good at resisting sideways forces.

- It’s hard and takes a long time to build micropiles, especially in tricky places.

- Micropiles cost more money than regular foundations because they need special materials and skilled workers.

- It’s difficult to know for sure how well micropiles will work because there isn’t a lot of information about them.

Faqs

Micropiles are small-diameter, deep foundation elements used in construction to support structures in challenging ground conditions or areas with specific design requirements.

The typical installation process involves drilling a high-strength steel casing into the ground to the desired depth. A reinforcing bar is inserted into the casing, and high-strength cement grout is pumped into the casing. The casing may extend either along the full length or only part of the pile.

Micropiles can be drilled using a removable bit or by using a sacrificial head attached to the steel casing. The choice of drilling method depends on the specific project requirements and ground conditions.

Yes, micropiles can be installed in restricted access sites with low headroom by using a technique called lagging. Lagging involves inserting wood, steel, or precast concrete panels behind the pile during excavation to provide support against the retained soil and transfer the load to the pile.

The load-bearing capacity of micropiles can be enhanced through a process called post-grouting. This involves injecting grout at high pressure within the bond length of the pile, increasing the frictional forces between the micropile and the surrounding soils and thereby achieving greater capacity.