Table of Contents

Introduction

Penicilline are bita-lactam antibiotics they have a β -lactam ring in their chemical structure

Penicilline was mainly produce by penicillium and Aspergillus species.

The story of Alexander flaming discovery of penicilline has been told often. Fleming was already well known for his earlier work on staphylococci when, upon returning from a long holiday in September 1928, he noted that one petri dish contained colonies of Staphylococcus except for clear area contaminated with a fungus that appeared to inhibit bacterial growth. Fleming identified the contaminant as a strain of Penicillium and he found that it killed a host of Gram-positive bacteria, including those that caused scarlet fever, pneumonia, Gonorrhea, meningitis and diphtheria.

Penicillins are a group of β -lactam antibiotics consisting of natural penicillins and semisynthetic penicillins. The basic structure of all penicillins, natural synthetic, is 6-aminopenicillanic acid composed of a four membered heterocyclic bita lactam ring fused with a five membered (benzylpenicillin), penicillin V (Phenoxy methyl penicillin), Thia Zolidine ring.

Commercial Production of Penicilline

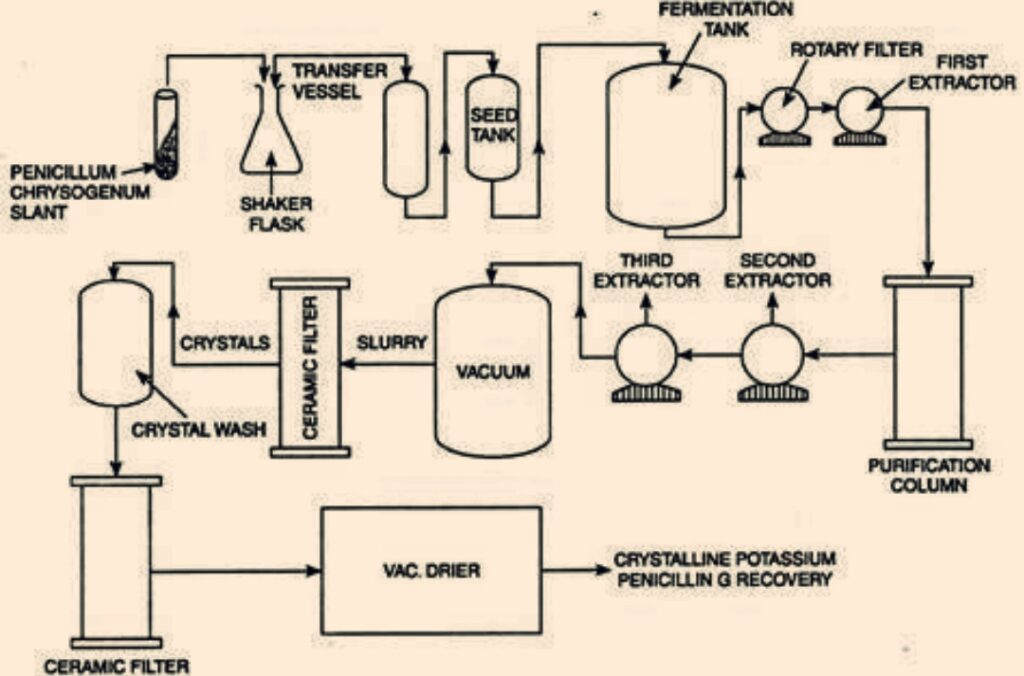

The commercial production of most of the antibiotics follows a similar plan. The major differences relate to the microorganism, media composition, and extraction procedure. For penicillin production, inoculum of a high yielding strain of P. Chrysogenium is prepared as follows: inoculum is first cultured in flasks in wheat bran nutrient solution for 1 week at 24°C.

The culture is then transferred to inoculum tanks, and grown for 1-2 days under aeration; this supports heavy mycelial growth. The inoculum is now added to very large fermenter containing the production medium, which consists of 10 per cent total glucose/molasses, 4-5% corn-steep liquor solids, 0.5-0.8 per cent phenylacetic acid and 0.5% vegetable oil; pH is adjusted to 6.0 and temperature is regulated at 25- 26°C.

The fermentation is carried out for 7 days. Initially, mycelial growth occurs, and carbohydrates are used up. This reduces the carbohydrate level in the medium; this favours penicillin production, which begins from the second day of fermentation. The pH of medium rises to 8.0 by the 7th day, and penicillin production stops at this stage. Phenylacetic acid is the precursor for the benzene ring side chain of Penicillin G.

Culture Media

In this study, several fermentation media were tested for the production of penicillin G acylase (PGA) using Bacillus mega Terium. The carbon sources studied were glucose and lactose. The nitrogen sources studied were enzymatic casein hydrolysates produced with proteases of different specificities. The replacement of glucose with cheese whey and the addition of free amino acids in the PGA production were also tested. The results showed a strong correlation between the nitrogen source and enzyme yield and the presence of glucose repression. The highest enzyme concentration achieved was 138 IU/L using casein hydrolyzed with 0.6 L of Alcalase and cheese whey.

The conventional penicillin fermentation medium is composed of corn steep liquor, glucose, lactose minerals oil and precursor.

History of Penicillin Production

On August 6, 1881, Alexander Fleming was born to Hugh Fleming and Grace Stirling Morton in Loch field Farm, Scotland. Initially schooled in Scotland, Fleming eventually moved to London with three brothers and a sister, and completed his youth education at the Regent Street Polytechnic.

He did not enter medical school immediately after; instead, he worked in a shipping office for four years.

When his uncle John died, he willed equal shares of his estate to his siblings, nieces and nephews, and Fleming was able to use his share to pursue a medical education.