Table of Contents

What Is Carbon Concrete?

Carbon concrete, an innovative construction material, combines the strength and durability of traditional concrete with the exceptional properties of carbon fibers or bars.

This composite material has the potential to revolutionize the field of infrastructure development by offering enhanced structural performance, sustainability, and design flexibility through advanced carbon reinforcement techniques.

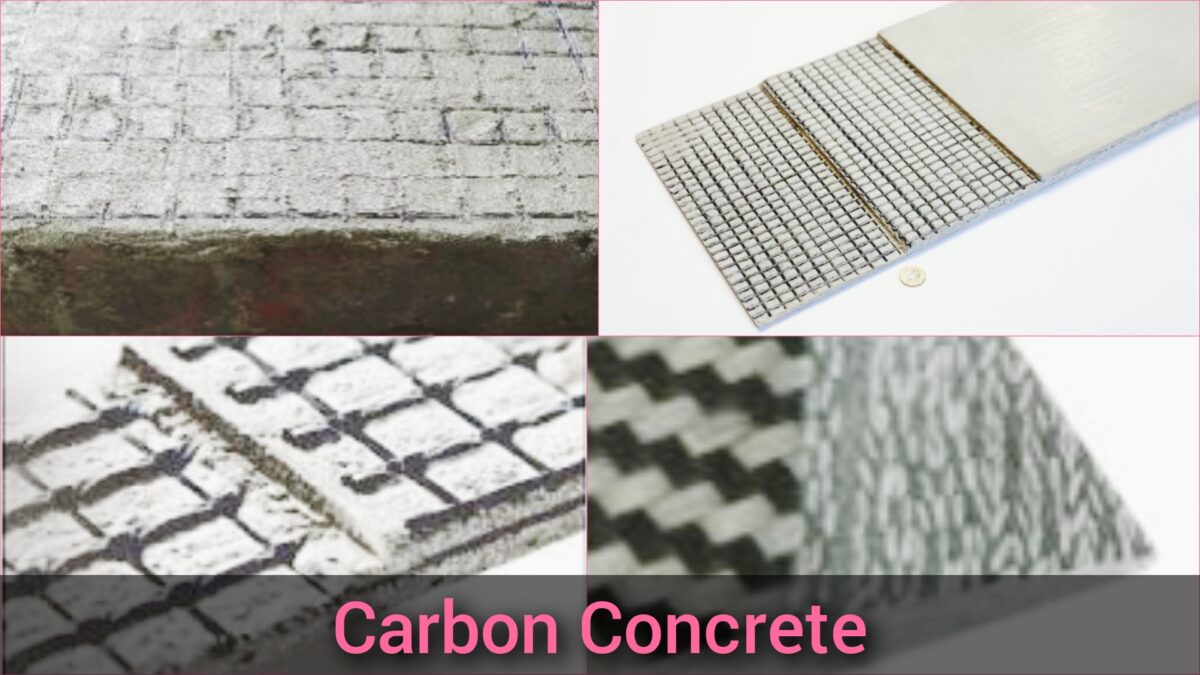

The integration of carbon fibers or bars within the concrete matrix is achieved through various methods, such as incorporating mesh-like textile mats between concrete layers or uniformly dispersing the carbon fibers throughout the mixture. Carbon reinforcement significantly improves the tensile strength of concrete, providing exceptional resistance to cracking and enhancing its overall structural integrity.

The outstanding strength-to-weight ratio of carbon concrete distinguishes it from conventional materials. By utilizing carbon fiber reinforcement, it surpasses the strength of traditional concrete while reducing its weight. This characteristic enables the construction of visually appealing and structurally efficient buildings.

Architects and engineers can explore innovative designs that were previously unattainable using conventional materials, thanks to the lightweight nature of carbon concrete.

Sustainability is a key driving force behind the adoption of carbon concrete. The manufacturing process aligns with resource-saving and eco-friendly practices. Its reduced material intensity and lighter composition contribute to sustainable construction.

Carbon concrete exhibits exceptional durability, leading to longer service life and reduced maintenance requirements. By choosing carbon concrete, the construction industry can embrace environmentally conscious practices without compromising performance.

How To Make Carbon Concrete

Carbon fiber can be effectively incorporated into concrete to create carbon concrete.

One method involves randomly dispersing carbon fibers throughout the concrete mixture.

Another technique involves utilizing mesh-like textile mats made from carbon fibers, which are positioned between layers of fine concrete.

Carbon fibers can be deliberately distributed throughout the concrete using a nozzle process, resulting in enhanced tensile strength. Carbon bars are employed to reinforce fine concrete, thus yielding high-performance carbon-reinforced concrete.

Benefits Of Carbon Concrete

- Carbon concrete reduces the embodied carbon emissions by half compared to conventional concrete, owing to reduced material consumption.

- Carbon concrete is four times lighter than conventional concrete, allowing for delicate and aesthetically pleasing designs in buildings and other structures.

- Carbon-based structures have a significantly longer lifespan compared to reinforced steel. For instance, in Germany, bridges made from reinforced steel typically have a lifespan of around 40-50 years, whereas the Albstadt bridge, constructed from textile-reinforced concrete, can last approximately 80 years without requiring extensive rehabilitation.

- Carbon fibers can be derived from various carbon-containing substances.

- Carbon fibers enhance concrete strength by five to six times compared to reinforced steel.

- Carbon does not corrode, eliminating the need for a thick concrete cover for corrosion protection in reinforced concrete structures.

Key Drawbacks

The higher cost of carbon fibers and the additional expertise required for its use generally make carbon concrete more expensive than traditional concrete. Budget-constrained projects may find it less economically viable.

The production of carbon fibers for carbon concrete involves substantial energy consumption and potential greenhouse gas emissions, resulting in a significant environmental footprint. Additionally, disposing of carbon fibers at the end of their lifecycle can present environmental challenges.

The limited availability of carbon fibers used in carbon concrete can cause delays and increase costs for construction projects. Sourcing carbon fibers in large quantities can be challenging, particularly for extensive projects.

Factors such as UV radiation, fire, and chemicals can damage the carbon fibers in carbon concrete, compromising its structural integrity and durability if the fibers are exposed or damaged.

Applications And Uses

Carbon concrete has many uses in different areas. It can be used to build houses, offices, and factories. The material is strong and long-lasting, allowing architects to create interesting and unique designs. Carbon concrete is also lightweight, which means structures can be made thinner without sacrificing strength. It is resistant to fire and corrosion, making it suitable for buildings in risky environments.

Infrastructure projects like bridges, tunnels, and highways can benefit from carbon concrete. It strengthens the structures and prevents cracking and wearing out. Because it is lightweight, it makes construction easier and cheaper. It is also resistant to corrosion, making it ideal for projects near the sea or in places with a lot of chemicals.

Carbon concrete is great for fixing and improving old buildings. It can reinforce weak parts and make them stronger. This extends the life of the structures and reduces the need for repairs in the future. Carbon concrete works well with existing materials, so it can be added to old buildings without changing their appearance.

Carbon concrete is useful for offshore structures like platforms and marine systems. These structures need to withstand tough conditions, such as strong winds and salty water. Carbon concrete is durable and doesn’t get damaged easily. It is also resistant to fire, which is important for safety in these areas.

Carbon concrete is helpful in preserving historical buildings. It is lightweight and can be used to reinforce old structures without changing their original look. This makes it easier to maintain the buildings and keep them standing for a long time. Carbon concrete is a good choice for protecting our important cultural sites.

Faqs

Carbon Concrete is made by mixing cement, aggregates, water, and carbon fibers together. We add the carbon fibers to the concrete mixture and then pour it onto the structure we want to build. After some time, it hardens and becomes a strong carbon fiber-reinforced concrete.

Yes, Carbon Concrete can be used in places with earthquakes. It is strong and can handle the shaking during an earthquake. The carbon fibers in the concrete make it more durable and flexible, so it doesn’t break easily.

Yes, Carbon Concrete is safe from fire. It can withstand high temperatures because of the carbon fibers in it. This means it doesn’t get damaged quickly when there is a fire. However, it’s still important to be careful and have fire safety measures in place.

We are still learning how to recycle Carbon Concrete, but we are making progress. Some ways have been found to take out and reuse the carbon fibers from old Carbon Concrete. People are doing research to find better ways to recycle it and make it more sustainable.

Although Carbon Concrete has many good things about it, there are some things to think about. It can cost more than regular concrete because the carbon fibers are expensive. It’s also a bit challenging to make sure the carbon fibers are evenly spread throughout the concrete. We are working on solving these problems and making Carbon Concrete even better.