Pressure relief valve is used to release extra pressure. This type of valve normally used in tanks and pipelines containing high pressure fluids. Its short form is PRV.

Predefined pressure is set in the pressure relief valve. When pressure exceeds beyond defined pressure, PRV released extra pressure. When pressure goes down, PRV closes again. This is completely automated process.

High pressure is always risky in the pipeline. Pressure relief valve is used to reduce the pressure in the pipeline. PRV provides stability and reduce risk of leakage.

Table of Contents

Importance of Pressure Relief Valve

Pipelines are designed to carry defined pressure. But, Sometimes system does not work normally. In this case, pressure in the pipeline can fluctuates. When pressure goes beyond the certain point, PRV opens and release the excessive pressure.

In case of emergency, pressure can be very high. To tackle this problem, PRV is used to control the pressure.

Pressure relief valves are safety devices. It activates automatically when pressure goes beyond the limit.

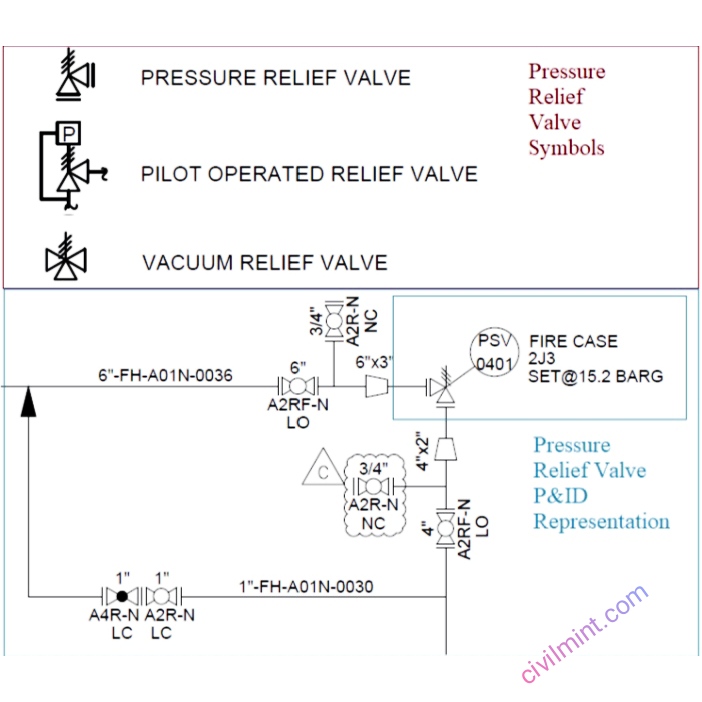

All the high pressure pipelines contains PRV. No of PRV is depend on pressure intensity and length of the pipeline. All the technical terms related to pressure relief valves are mentioned in the P&ID drawings.

Types of Pressure Relief Valves

Three main types of pressure relief valves are used in industrial applications.

1. Relief Valve

- Adjustable

- Electronic

2. Safety Valve

- Low Lift

- High lift

- Full lift

3. Safety Relief Valve

- Conventional spring-loaded safety relief valve

- Pilot operated relief valve

- Balanced-bellows type relief valve

- Power actuated relief valve

- Temperature and Pressure actuated relief valve

How Does Pressure Relief Valve Work?

Diffrent types of pressure relief valves have different working concept.

In a spring-loaded pressure relief valve, the spring force holds the disk at position keeping the valve in a closed position. When pressure goes beyond the defined pressure, the disk starts to lift allowing the fluid to flow through the outlet and releasing

pressure. When pressure reduced, the spring force the spring pushes

back the disk in positive to close the valve preventing further release of fluid.

In pilot-operated pressure relief valves, inlet pressure of the pipe is sent to a small safety

valve that works on top of the piston. The top area of the piston is designed in such a way that the bottom area under fluid contact, the pressure on top is higher which pushes the piston

to close the relief valve. When the inlet pressure rises above the predefined pressure, a net

upward force acts on the piston forcing the piston to pop-up and release the pressure.

Advantages of Pressure Relief Valve

1. It is used to reduce extra pressure from the pipe.

2. It is also used in fluid tanks to maintain the pressure.

3. These are safety valves. It prevents sudden rise in pressure.

4. PRV prevents sudden leakage from the pipe.

5. No extra pressure on the piping material.

Conclusion

In this article, I have described about Pressure Relief Valve (PRV) in a very simple way. The main function of the pressure relief valve is to release the extra pressure.