A plug valve is a kind of valve that makes use of a tapered or cylindrical “plug” to regulate the flow of fluid in the system. The plug of the valve rotates inside the valve body. This plug has one or more hollow passages or openings.

When the valve opens, fluid flows through these hollow channels in the plug. Chick cocks have a simple structure and are usually very cheap. If the stopper is tapered, the handle or shaft is usually connected to the large diameter end of the stopper. This valve does not have a bonnet, but it usually has a handle attached to the end of the cone. This handle is on the outside of the valve body. The valve handle and stem are usually integrated into one simple design. The handle is usually an L-shaped design. The other end of the plug also extends outward, but there is a mechanism to secure the plug inside the valve body.

The port acts as an opening in the valve body that allows liquid to enter and exit. This is because the ports are usually attached to both ends of the valve body. Therefore, it takes 1/4 turn to move the connector from the open position to the closed position. Therefore, this valve is also called a 1/4 turn valve. There is usually a mechanism to limit the movement of the handle to 1/4 turn. The slightly tapered metal plug valve is also used as a simple shutoff valve for natural gas service lines.

Table of Contents

Working Concept of Plug Valve

The frame of the plug valve has a parallel or conical seat wherein a plug is installed. This plug has one or greater ports. The function of those ports comes to a decision regarding the open or closed function of the valve. The port of the valve is likewise known as a passageway or establishing via which media enters and exits.

Rotate the stopper 90 degrees to completely open and close the liquid flow. The efficiency of these valves is not as good as that of ball valves. They can only be operated in a fully closed or fully open state. When the plug port is lined up with the inlet and outlet ports, fluid begins to flow into the valve. Pressure drops can also occur over the reduced area of the port. This pressure drop can be reduced by using a full cylindrical cone.

When the operator turns the handle completely 90 ° (or 1/4 turn), the opening of the stopper forms a 90 ° angle to the flowing liquid and the end of the stopper is a sealing device (lubricant, sleeve, etc.). Rotate through. ). When the 90 ° rotation of the plug is complete, the opening of the plug becomes perpendicular to the flow, the liquid flow stops completely and the valve closes. The throttle will rotate the cone at 45 °. In such a position, the plug can reduce the pressure twice as much as normal. Moving the plug away from the fully open position reduces the flow area of the inlet orifice at the pressure drop point. The flow then enters the entire port area of the cone where the pressure recovery process takes place.

The simple cone valve is ideal for low-temperature and low-pressure applications that can be manufactured in a variety of sizes from 240mm to 310mm. Due to the large changes in medium temperature, the expansion difference of the plug valve is unavoidable, resulting in loss of airtightness and excessive operating rigidity.

Types of Plug Valves

- Lubricated valve

- Non-Lubricated valve

- Multi-Port plug valve

- Eccentric valve

- Expanding valve

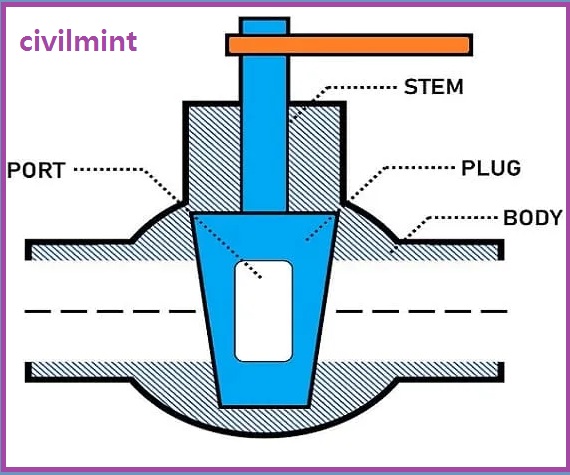

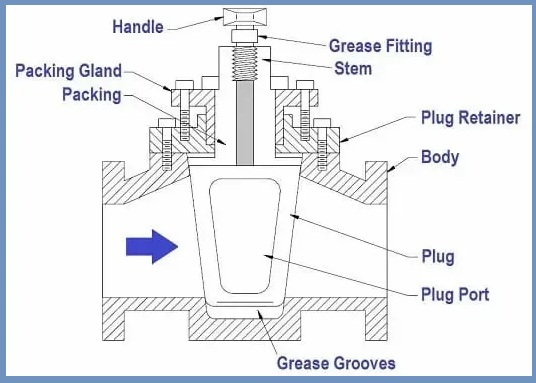

Parts of the Plug Valve

- Valve Body

- Stem

- Handle

- Plug Ports

- Plug disc

Refer to the below figure to better visualize.

Pros

- It has a simple structure and operation.

- It has fewer rotating parts.

- This valve opens and closes the flow of liquid very quickly.

- It requires very little maintenance.

- Plug valves provide very low flow resistance.

- It provides a tighter seal than ball valves. It has a low initial cost.

- These valves are easy to maintain.

- It can be disassembled easily for maintenance and cleaning.

Cons

- It is heavier than a ball valve.

- You cannot manually operate the large chick cock. Therefore, actuators are required to operate them.

- These are not optimal for throttle service.

- This valve has a large frictional force, so a high operating force is required.

- There is pressure loss due to reduced connections.

Uses

- Plug valves are used to open and close the flow of liquid.

- Plug valves are used in sewage, sludge, slurries, hydrocarbons, steam, and gas applications.

- It is also used in various compressors and pumps.

- They are used in low pressure, low temperature, high pressure, and high-temperature applications.