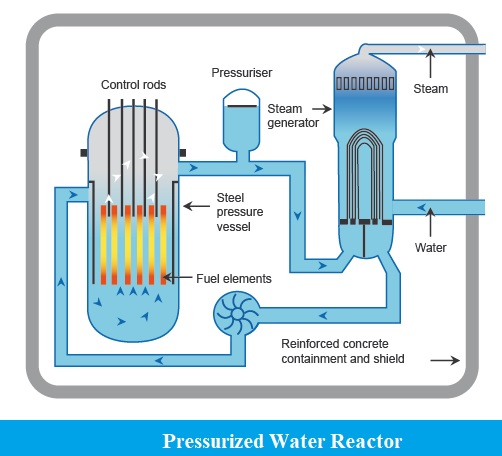

A pressurized water reactor (PWR) is a typical light-water nuclear reactor.

The fantastic properties of water as a mediator and coolant make the Pressurized Water Reactor (PWR) a characteristic decision for power reactors. The main restriction on a PWR is the basic temperature of the water, 374°C. This is the greatest conceivable temperature of a coolant in the reactor and in practice it is considerably less, perhaps about 300°C, to permit an edge of security. In a PWR, the coolant pressure should be more prominent than the immersion pressure at, say, 300°C (85.93 bar) to stifle bubbling. The pressing factor is kept up at around 155 bar to forestall mass bubbling.

A high pressing factor is applied to atomic reactors during tasks, and the cooling water inside the reactor arrives at a high temperature without bubbling. This high-temperature essential cooling water is gone through the steam generator to heat the auxiliary cooling water, where it cools itself prior to being gotten back to the reactor. The auxiliary cooling water heated in the steam generator goes to steam and is utilized to turn the turbine generator, which produces power.

A typical pressurized reactor consists of two loops in series. The first loop is the coolant loop while the second loop is called the working fluid loop.

The coolant picks up the heat in the reactor and transfers it to the working fluid loop in the steam generator. The steam is then utilized in a Rankine-type cycle to generate electric power.

Advantages of Pressurized Water Reactor

- Pressurized water reactor (PWR) reactors are truly steady because of their inclination to create less power as temperatures increment; this makes the reactor simpler to work from a security outlook.

- Pressurized water reactor (PWR) turbine cycle circle is discrete from the essential circle, so the water in the auxiliary circle isn’t sullied by radioactive materials.

- Pressurized water reactors (PWR) can latently skedaddle the reactor in the event that offsite power is lost to promptly stop the essential atomic response. The control bars are held by electromagnets and fall by gravity when current is lost; full addition securely closes down the essential atomic response.

- Pressurized water reactor (PWR) innovation is inclined toward by countries looking to foster an atomic naval force; the minimal reactors fit well in atomic submarines and other atomic boats.

- Pressurized water reactors (PWR) are the most conveyed sort of reactor universally, taking into account a wide scope of providers of new plants and parts for existing plants. Because of long involvement in their activity they are the nearest thing to develop innovation that exists in thermal power.

- Pressurized water reactors (PWR) – relying upon type – can be powered with MOX-fuel as well as the Russian Remix Fuel taking into account a shut atomic fuel cycle.

Disadvantages of Pressurized Water Reactor

- The coolant water should be profoundly compressed to stay fluid at high temperatures. This requires high strength channeling and a weighty tension vessel and subsequently increments development costs. The higher tension can expand the outcomes of a deficiency of-coolant accident. The reactor pressure vessel is made from bendable steel be that as it may, as the plant is worked, neutron transition from the reactor makes this steel become less flexible. In the end the flexibility of the steel will arrive not set in stone by the relevant evaporator and pressure vessel norms, and the strain vessel should be fixed or supplanted. This probably won’t be down to earth or financial, thus decides the existence of the plant.

- Extra high tension parts, for example, reactor coolant siphons, pressurizers, and steam generators are additionally required. This additionally builds the capital expense and intricacy of a PWR power plant.

- The high-temperature water coolant with boric corrosive broke up in it is destructive to carbon steel (yet not hardened steel); this can make radioactive consumption items circle in the essential coolant circle. This restricts the lifetime of the reactor, however the frameworks that channel out the erosion items and change the boric corrosive fixation add essentially to the general expense of the reactor and to radiation openness. In one case, this has brought about serious erosion to control pole drive instruments when the boric corrosive arrangement spilled through the seal between the actual component and the essential system.

- Because of the prerequisite to stack a compressed water reactor’s essential coolant circle with boron, unwanted radioactive optional tritium creation in the water is north of 25 times more prominent than in bubbling water reactors of comparative power, attributable to the last’s shortfall of the neutron directing component in its coolant circle. The tritium is made by the retention of a quick neutron in the core of a boron-10 particle which hence parts into a lithium-7 and tritium iota. Compressed water reactors yearly transmit a few hundred curies of tritium to the climate as a feature of typical operation.

- Normal uranium is just 0.7% uranium-235, the isotope important for warm reactors. This makes it important to enhance the uranium fuel, which fundamentally expands the expenses of fuel creation.

- Since water goes about as a neutron arbitrator, it is unimaginable to expect to construct a quick neutron reactor with a PWR plant. A decreased control water reactor may anyway accomplish a rearing proportion more noteworthy than solidarity, however, this reactor configuration has detriments of its own.[24]

- Spent fuel from a PWR normally has a higher substance of fissile material than regular uranium. Without atomic going back over, this fissile material can’t be utilized as a fuel in a PWR.