Table of Contents

Pump Performance Curve

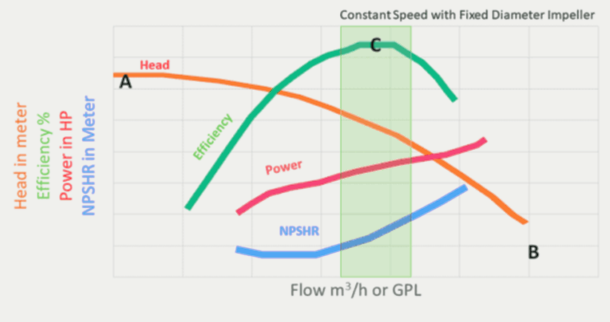

A pump performance curve is a design analysis (or display) of a pump, how it performs in relation to changes in operating parameters such as pressure (head is derived from pressure) and flow.

Operating parameter dependent factors are head, shut-off height, impeller diameter, efficiency, NPHSR, and power consumption. These terms are explained later in this article.

Generally, pump performance curves are created by the original equipment manufacturer.

Detailed Description

A pump is a device that converts mechanical energy into hydraulic pressure with the help of an external source, possibly centrifugal force due to an electric motor. This centrifugal force is generated by the rotation of the impeller on the suction port of the pump and helps move the liquid from one place to another through the outlet of the discharge nozzle. The type of pump can be centrifugal or positive displacement, and the mechanism changes accordingly.

A pump performance curve is a very important chart produced by a pump manufacturer. They provide information about how various parameters such as desired NPSH value, efficiency, and power requirements behave when the flow changes. In order to select the right pump for a particular service, the technician must be able to read the performance curve of the pump. A pump performance curve is also called a pump efficiency curve, a pump selection curve, a pump curve, or simply a pump curve.

Types of Pump Performance Curve

Normally there are 5 types of pump performance curve are used as listed below.

- Head V/S Flow (H-Q Curve)

- NPSHR curve

- Efficiency Curve

- Power Consumption Curve

- Family Curve

Closing Words

In this article, I have described pump performance curve in a very simple way. Pump performance curve is used to select the right pump for the specific needs of your application.