Table of Contents

What are Rebar Couplers?

Rebar couplers are used to joined steel bars together. Normally ends of steel bars are joined. These types of couplers are used in reinforced concrete structures to modify the reinforcement wrapping and welding system. Coupling is used when longer rods are needed or when additional rods are attached to the ends of existing rods joined side by side by wire.

Welded and overlapping systems waste reinforcement and alternative systems known as rebar couplings are used to provide continuous connections for continuous reinforcement for each structure.

Clutches are cheap and cost-effective, unlike wrap systems where the wrap wastes part of the rod. Couplings are often referred to as mechanical joints. It is used for general construction works such as buildings, bridges, dams and steel towers.

We got some idea about debar couplers. Now, let’s know about different types of rebar couplers.

Types of Rebar Couplers

Normally 4 types of rebar couplers are used in industrial applications as listed below.

- Roll Screw Rebar Couplers

- Cold Forged Rebar Couplers

- Crimp Fitting Rebar Couplers

- MBT Rebar Couplers

I described these 4 types of rebar couplers in detail.

1. Roll Screw Rebar Couplers

With this coupler, the coupler is threaded by a thread machine. Thread the end of the TMT rod into the rolling device to hold the rod to the rolling screw coupler.

A hitch is then attached to each end of the TMT rod like a nut and bolt for continuous reinforcement.

2. Cold Forged Rebar Couplers

Cold stuffed couplers are also threaded using threading machines like rebar roll thread couplers. However, in this clutch the TMT rod tips are developed hydraulically to the advantage of a forging machine.

After the end of the TMT rod is forged, the minimum part of its length and thickness is lost and the rod is threaded by a threading machine and attached to the coupling. Awarded for major infrastructure projects and other government projects.

3. Crimp Fitting Rebar Couplers

This is also known as the first coupler in structural reinforcement, after which the threaded coupler was introduced. Crimp rebar couplers do not have threads.

A rebar coupler is attached to each end of the unthreaded TMT rod and the coupler is crimped with a crimping machine. Crimp couplings are less economical, use more material, and have higher labor costs.

Rebar crimp sleeves cannot be loosened after installation. This is why crimp coupling systems have failed in the market.

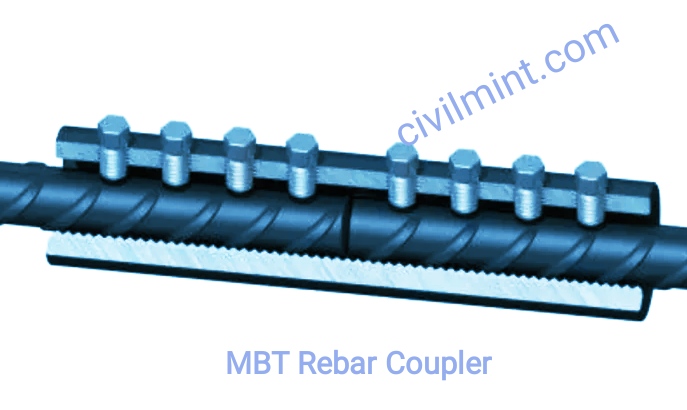

4. MBT Rebar Coupler

MBT Reinforcement Couplings are available to meet the essential requirements of continuous reinforcement.

MBT couplers are used for reinforcement when the length of the overlap is short and there are not many bars left for continuous reinforcement. It is also used in retrofit designs. The upper MBT coupling has about 6-8 screws. Its length is longer than that of threaded couplings. The strength of this coupling depends on the number of screws there, and these screws are used to secure the coupling to the stiffener.

Uses of Rebar Couplers

Rebar couplers are used in place of regular rebar wrap splices in reinforced concrete structures. Couplings are also suitable for use on reinforced concrete columns and walls.

Pros

- Load transfer is reasonable.

- Good quality control and easy to use.

- Couplers do not clog.

- Reinforcement couplings are very economical compared to all connection systems of reinforcement.

- Improves structural integrity.

- Couplers reduce overlap length analysis.

- Improve your bar service by not wasting your bar like wrapping.

- Couplers extend working speed in short installments.

- Connection check is easy and simple.

Cons

- Misalignment can occur when mounting two shafts, which puts extreme forces on couplings, bearings, and shafts, leading to premature wear.

- It is difficult to find a clutch on the market with a diameter greater than 32mm.

- Assembly process requires qualified personnel. if the quality of the coupling does not match the quality of the rebar, structural damage can occur.