Table of Contents

Introduction of Tilt and Shift

Tilt and shift usually occur during the subsidence phase of the well foundation. If not handled carefully, it can cause serious problems that weaken the stability of the foundation. In this article, I have described all the important things related to tilt and shift of well foundation.

What is Tilt in Well Foundation

If the well is tilted from the vertical, it is said to have a well foundation tilt.

What is Shift in Well Foundation

When a well moves horizontally away from its intended location, this is known as well shift movement.

Precautions for Slippage and fall prevention

Various safety measures are applied to prevent shift and tilt of a well foundation. Some important precautionary measures are given below.

- The well curb diameter should be larger than the outside diameter of the stein. A diameter of 40 to 80 mm is generally recommended.

- It should be placed symmetrically on the curb.

- The outer surface of the curb must be smooth.

- All sides should be dredged evenly. The cutting edge should be evenly thick and sharp.

Calculation of Tilt and Shift of Well Foundation

- The maximum allowable slope for well foundations is 1 in 60.

- Well foundation displacement should not exceed 1% of the drilling depth.

- If the above limits are exceeded, the borehole foundation is considered unsafe and in such cases corrective action must be taken to correct the displacement and tilt.

Rectification of Tilts and Shifts in Well Foundation

There are various rectification methods of tilts and shifts in well foundation. I have listed some common methode used in construction industry.

- Well Pulling

- Hydraulic Jack System

- Props Method

- Drilling Under Cutting Edge

- Wood Sleepers Under Cutting Edge

- Eccentric Load Technique

- Excavation on the Hill Side

- Water jetting

Let’s know in detail about various rectification methods of tilts and shifts in well foundation.

1. Well Pulling

The fountain can be pulled higher with a steel cable. One or more steel cables are wrapped around the shaft and wooden sleepers are stuffed between the shaft and the cable to prevent damage to the shaft stein.

Pulling must be done carefully. Otherwise, the foundation of the well may shift.

2. Hydraulic Jack System

Another method of correcting foundation tilt and movement is to use a hydraulic or mechanical jack. You can push the inclined shaft from one side to the higher side.

Adjacent vertical well foundations or suitable fixtures support the siphon system. Be careful when pushing the drill hole. Otherwise, the drilled holes may be misaligned.

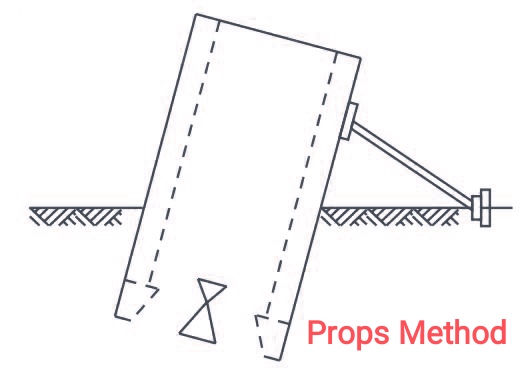

3. Props Method

A stilt at the bottom or slope of the well can prevent further tipping.

Install wooden sleepers between the pillars and the well rocks to prevent damage to the well rocks and prevent pressure from spreading over a wider area.

The strut rests on a solid base with a tamped pile.

4. Drilling Under Cutting Edge

This technique is used for the hard layers of the earth. In this method, the well is first drained and an excavation is made just below the cutting edge on the higher side.

If drainage is not possible, use appropriate equipment and professional divers to loosen the soil layer.

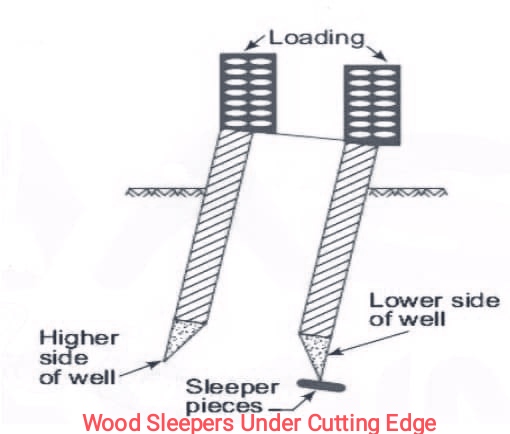

5. Wood Sleepers Under Cutting Edge

If the downward slope becomes large, insert a wooden sleeper under the lower cutting edge to temporarily reduce the slope.

These knots can be removed once the well is fixed to a vertical level.

6. Eccentric Load Technique

By placing the eccentric load on the upper side, the inclination of the hole can be corrected. The high side is nothing but the opposite or low side of the slope.

Install a loading platform on the higher side and load on top of it.

This eccentric load increases the downward pressure on the high side and corrects the tilt. The subsidence depth determines the load capacity and eccentricity.

The greater the borehole depth, the greater the eccentricity and stress.

7. Excavation on the Hill Side

If the well is sloping to one side, the amount of drilling should be increased on the opposite side.

This technique is useful only in the early stages of well drilling.

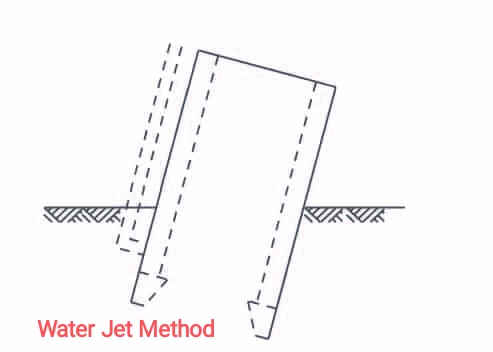

8. Water Jet Method

Injecting water on the outside high side of the well is also an improvement to correct the slope.

When the water jet is pressed against the fountain surface, the friction between the ground and the fountain surface is reduced, lowering the high side of the fountain and making the fountain vertical.