Torsion springs are elastic materials that, when twisted, exert a moment that resists rotation. Common types of torsion springs include spiral torsion springs, torsion bars, and spirally wound torsion springs.

Table of Contents

Types of Torsion Springs

- Single Helical torsion spring

- Double helical torsion spring

- Torsion bar spring

- Spiral wound torsion spring

Let’s have a look at these types of torsion springs.

1. Single Helical torsion spring

These types of springs are made from a material, usually spring steel, spring wire, and are formed into a helical shape. At each end, the torsion line expands to form two straight pins through which torque is applied. A rotating shaft inside the coil, or a circular housing around the coil, is used to determine the position of the spring. The pins typically extend tangentially, resulting in minimal stress. However, radial and axial lugs are also sometimes used.

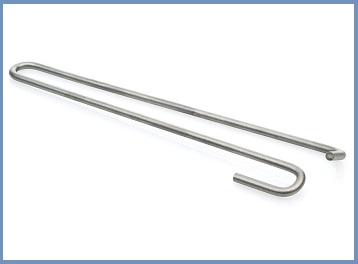

2. Double helical torsion spring

The dual coil version is basically two single coil springs that mirror each other and the coils are concentric but have opposite windings.

3. Torsion bar spring

A torsion bar spring is a simple straight bar made of elastic material that can be twisted to the limit of elasticity. Torsion bars are usually made of steel or rubber. They are commonly used in heavy-duty applications such as trucks and tank suspensions. The torsion bar suspension is extremely durable due to its mechanical simplicity. It’s also compact, so it’s easy to customize. Very light torsion bars may require tension to generate a restoring torque called torsion fiber.

4. Spiral wound torsion spring

A spirally wound torsion spring is formed by winding a spring wire, or more generally a thin strip of spring steel, around a flat coil. This configuration allows for large angular displacements of many rotations with relatively little torque change during movement. Therefore, spirally wound torsion springs are used in watch movements, watches, and other devices that need to store and release energy in this way. Drive springs are a special type of coil spring that can apply a constant torque over many revolutions. They are also sometimes called clock springs or motor springs. The royal fern is tightly wrapped around the housing to provide high energy density.