Operational speed and efficiency can be optimized if you’re using the right mechanical devices. If you’re ready to bring your company to the next level and you’re looking for mechanical devices that can speed up and optimize your daily workflow operation, you should be looking for conveyors.

Table of Contents

Conveyors

Conveyors are powerful mechanical devices that can transport materials from point A to point B in no time and with minimum effort. You need a conveyor if your operation is highly reliant on moving materials from one location to another. Conveyors are fixed devices that smoothly allow materials to be transported through them. You see conveyors in airports and industrial spaces.

Parts of a Conveyor

All conveyors mainly have the following parts:

- Frame – the fixed body that allows for efficient transport.

- Rollers – the part that allows for seamless material movement.

- Wheels – the part that allows for smooth transition and transportation of materials.

- Belt – the part where materials are placed. It highly relies on a conveyor belt lifter that allows for smooth, versatile, and easy material transport.

Conveyor Power

A conveyor can be powered manually, by gravity, or by a motor.

9 Types of Conveyors

To effectively optimize your workflow operation, you should at least have an idea of the different kinds of conveyors. By having a general idea of each, you’d be able to intelligently determine which one is best for your daily operational needs. You’d even get to evaluate if you’d need just one kind or a combination of different kinds. The different kinds of conveyors are as follows:

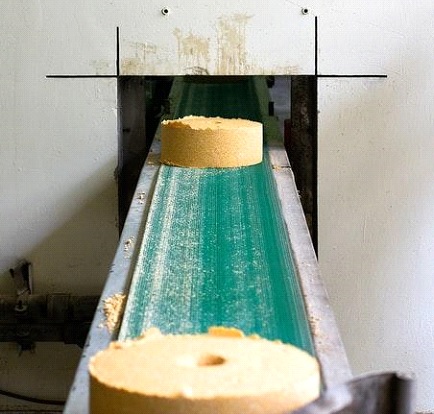

1. Belt Conveyors

Belt conveyors handle materials by using continuous belts. It has a flexible belt and an endless flat with metallic pulleys on both ends. Materials are transported through its belt. Belt conveyors are motor-powered.

The different kinds of belt conveyors are as follows:

- Flat belt conveyor

- Troughed belt conveyor

- Closed belt conveyor

- Metallic belt conveyor

- Portable conveyor

- Rope-driven conveyor

- Submerged belt conveyor

2. Chain Conveyors

Chain conveyors are composed of conveyors of different types. A chain conveyor has numerous strands with endless chains. Its strands are driven by sprockets. Materials are transported by attaching them to the links or on elements attached to the chain.

The different kinds of chain conveyors are as follows:

- Apron or pan conveyor

- Cross-bar or arm conveyor

- Car-type conveyor

- Flat-top chain conveyor and carrier chain

- Trolley conveyor

- Power and free conveyor

- Suspended tray conveyor

3. Haulage Conveyors

A haulage conveyor is a special kind of chain conveyor. It transports materials by dragging, pushing, or towing with the use of chains. Some users use cables instead of chains. Haulage conveyors run at a slow speed and need very little maintenance.

The different kinds of haulage conveyors are as follows:

- Drag chain conveyor

- Flight conveyor

- Tow conveyor

4. Cable Conveyor

Cable conveyors can transport people or big bulks of materials. Its mechanism is dependent on moving cables with one or more spans. Most people refer to cable conveyors as cable cars. Cable conveyors can cover long distances of many kilometers. They are also known as ‘aerial tramways’ or ‘ropeways’. They are commonly used in mines to transport minerals. Materials transported via cable cars can be automatically discharged on a destined discharge point.

5. Bucket Conveyor

Bucket conveyors transport loads of materials through bucket-shaped containers attached to a belt or moving chains. You will greatly benefit from using bucket conveyors if you need to transport bulks of materials from a low area to a high area.

The following are the different kinds of bucket conveyors:

- Centrifugal discharge elevators

- Positive discharge elevators

- Continuous discharge elevators

6. Roller Conveyor

A roller conveyor is composed of a series of rollers placed with fixed spacing. This type of conveyor does not have a belt. It is the rollers themselves that move and transport materials. They’re perfect for transporting materials with at least one solid and flat surface. They can easily transport boxes, logs, crates, and pipes.

7. Screw Conveyor

A screw conveyor is composed of a continuous helical screw that is connected to a rotating shaft. It can seamlessly transport finely grained materials in bulk via its trough. The material moves through a rotating screw. A screw conveyor can easily transport granular non-viscous items or pulverized material even at high temperatures.

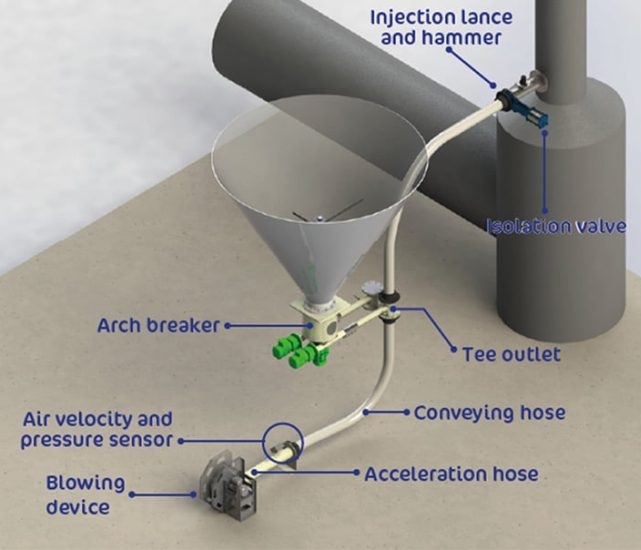

8. Pneumatic Conveyors

Pneumatic conveyors use gas to transport materials. Granulated and powdered materials can be seamlessly transported by pneumatic conveyors. Transportation is done with the help of flowing air that flows from one end to another end of a pipe. Motion is supported by utilizing fast-moving air.

A pneumatic conveyor is ideal for transporting non-sticky and dry materials. As it allows for movement through the air, it allows materials to remain pure and free from contamination. This is also why pneumatic conveyors are also perfect for fire-prone materials that need sensitive handling.

A pneumatic conveyor system needs the following:

- Air supply equipment – compressor or blower

- Product storages

- Pipelines

- Airlock feeders

- . Dust filters

The different kinds of pneumatic conveyors are as follows:

- Tube conveyors

- Air-activated gravity conveyors

9. Hydraulic Conveyors

Hydraulic conveyors transport materials with the use of water. It has pipes or channels with streams of water where materials can pass through. A pulp is formed when water mixes with materials. Mining industries and construction industries use hydraulic conveyors to dispose of ash and slag, deliver sand and water to mines, and fill lands.