There are various types of valves are used in the plumbing system. Some popular types of valves are ball valves, gate valves, butterfly valves, globe valves, and pressure reducing valves.

Table of Contents

Types of Valves Used in Plumbing System

- Ball valve

- Gate valve

- Butterfly valve

- Globe valve

- Pressure-reducing valve.

- Check Valve

- Plug valve

- Needle Valve

- Pinch Valve

- Tesla Valve

1. Ball valve

Ball valves are the most widely used in plumbing. Internally, this valve is a ball with a hole in the center and connects to an external lever-type handle at the top to control the flow of water.

When the handle is parallel to the liquid supply pipe, the valve opens. The valve closes when perpendicular to the supply pipe.

2. Gate valve

Gate valves are also the most widely used fittings in piping systems. Gate valves use a wedge-shaped metal knob or knob on top to lower or raise an inner gate to control the flow of water or liquid.

This valve has the same function as a ball valve, which cannot control the flow of fluid, and the flow is either fully open or fully closed.

Gate valves are suitable for circulating different types of liquids such as fuel gas, steam, lubricating oil, hydrocarbon, etc.

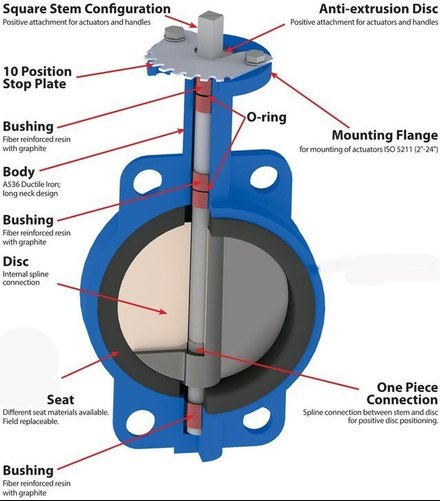

3. Butterfly valve

Butterfly valves are small round knobs on the side that are used to stop and regulate the flow of fluid. It consists of a rotating metal disk inside a valve that stops or regulates the flow of fluid.

This type of valve is relatively lighter and more compact than other types of valves.

4. Globe valve

Globe valves are best suited for piping valves that require precise flow control. These valves have stoppers that raise or lower to control fluid flow inside the valve. Raising and lowering of the stopper are performed using a round handle at the top.

5. Pressure-reducing valve

Pressure-reducing valves are used to control or reduce the pressure of water or liquid to the desired limit and prevent rupture of piping system damage.

These valves are commonly used in homes to obtain relatively high-pressure water from city water supplies.

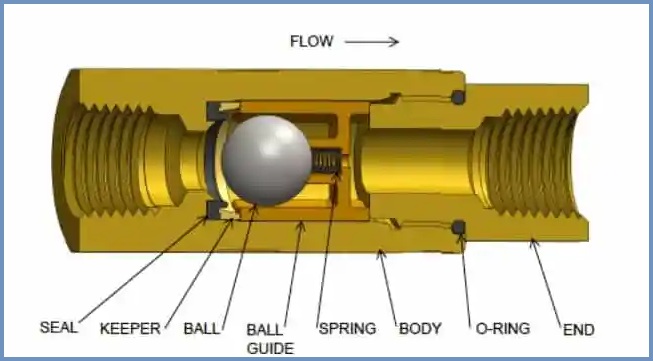

6. Check Valve

A plumbing valve used to prevent backflow in a plumbing system is called a check valve. Also non-return valve or NRV. The pressure of the liquid passing through the pipeline causes the valve to open and close when the flow direction is changed.

7. Plug valve

This type of valve is a quarter-turn action that uses a conical or cylindrical plug to stop or start flow. A disk plug is shaped like a passageway through which the flow passes. Plug valves are used as on-off stop valves and provide reliable shutoff. Plug valves can be used in vacuum for high pressure and high-temperature applications.

8. Needle Valve

Needle valves are similar in design to ball valves, but the main difference is that they have a sharp needle disc. Needle valves are designed for very precise flow control in small diameter piping systems.

They get their name from their pointed conical discs and matching seats. Needle valves are manual valves used to continuously regulate flow for regulation. Needle valves are similar in design to ball valves, but the main difference is the sharp needle disc.

9. Pinch Valve

A pinch valve is also called a clamp valve. This is a linear speed valve. Used to start, regulate, and stop fluid flow. A rubber tube, also known as a pinch tube, and a pinch mechanism are used to control the fluid.

Pinch valves are ideal for systems that efficiently transport slurries, solids-heavy liquids, and solids. A pinch valve is also called a clamp valve. This is a linear speed valve. Used to start, regulate, and stop fluid flow.

Fluids are controlled using a rubber tube, also known as a pinch tube and pinch mechanism. This valve is the simplest of all plumbing valves. Most pinch valves are the open type with the pinch tube open. However, in other styles, the pinch tube is completely surrounded by a metal case.

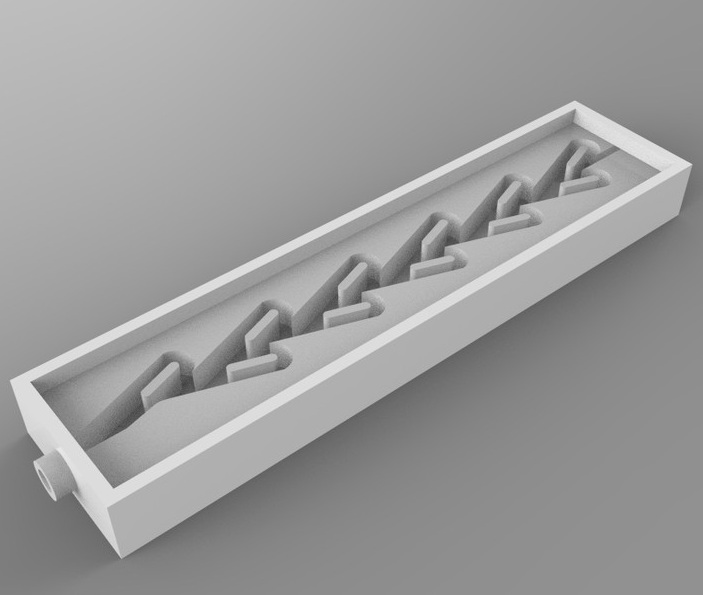

10. Tesla Valve

The Tesla valve, which the inventors call the valvular conduit, is a fixed geometry passive check valve. This allows the fluid to flow preferably in one direction without moving parts. The device was named after Nikola Tesla.

Because there are no moving parts, Tesla valves are much more resistant to wear and fatigue, especially in applications with frequent pressure changes, such as pulse jet applications.

Tesla valves are used in microfluidic applications and offer advantages such as scalability, durability, and ease of manufacture in a variety of materials. It is also used in microfluidic applications.