Table of Contents

Introduction of Sunk Key

A sunk key is a particular type of key that fits half in a keyway on a pulley and the other half in a keyway on a shaft.

Check out the below image of sunk keys.

Function of Sunk Key

When the key is depressed, the force is transmitted by the shear force of the key. Relative movement between shaft and hub is also prevented by the shear strength of the key. Flush keys are therefore suitable for heavy duty applications as there is no possibility of the key slipping around the shaft.

These key types are form fit drives. This is the main advantage of recessed keys over saddle keys. However, it is necessary to machine a keyway on both the shaft and hub. As a result, sinker wedge connections are more expensive than saddle wedge connections.

In practice, square or rectangular recessed keys are widely used. Countersunk keys with a rectangular cross section are called flat keys.

Square wrench used for general industrial machinery. Flat keys are useful for machine tool applications where additional joint strength is required.

Types of Sunk Keys

Diffrent types of sunk key are listed below.

- Round or Circular Key

- Woodruff Key

- Parallel Sunk Key

- Rectangular or Flat Key

- Square Key

- Gib Head Key

- Feather Key

We will discuss types of sunk keys in detail.

Lets start!

1. Round or Circular Key

These circular key have a circular cross-section and are drilled partly into the hub hole and partly into the shaft.

A big advantage of using a round key is that the key hole can be re-drilled after the mating is installed.

Usually best for low power drives. This type of key is a taper in 1:50.

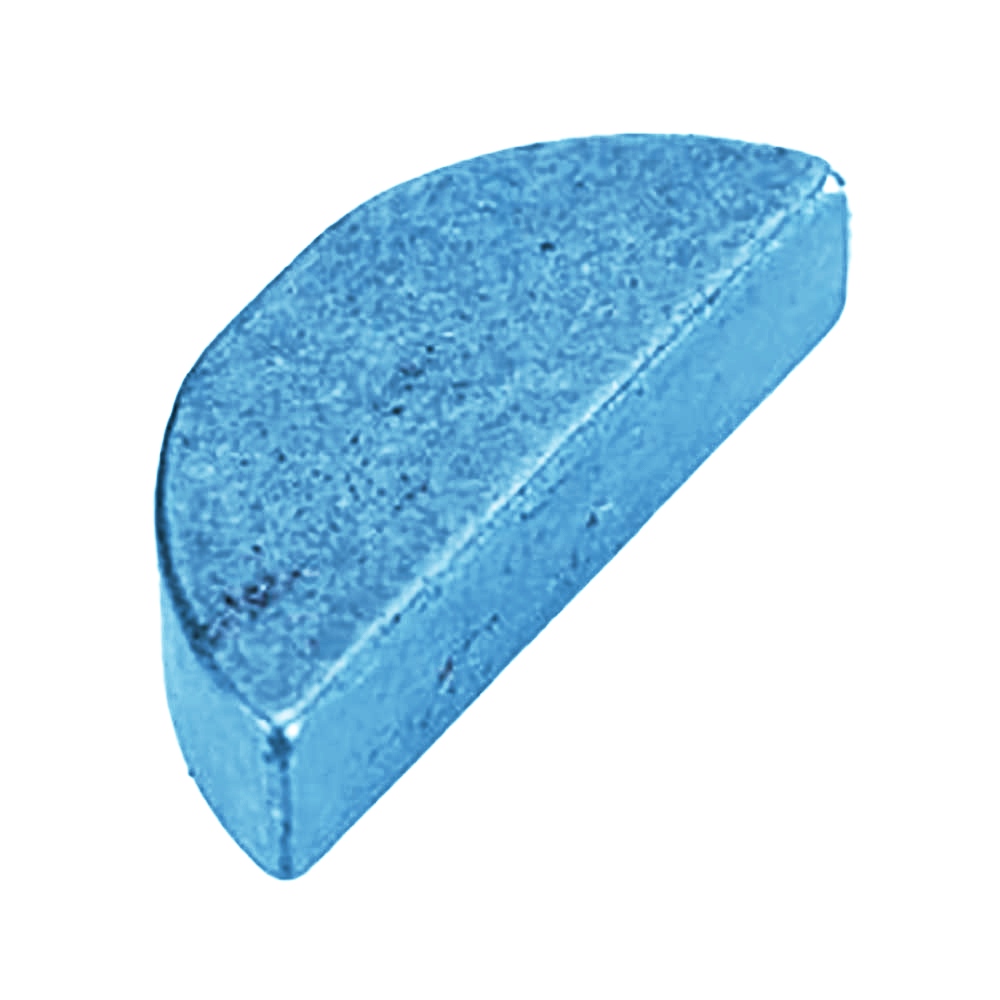

2. Woodruff Key

The top of the woodruff key is flat and the bottom is semi-circular.

Woodruff Key can be tilted and aligned with the shaft.

In order for the woodruff key to fit the shaft, the keyway needs to be deeper. This will prevent the shaft and hub from slipping.

Woodruff keys are primarily used to improve shaft concentricity at high speeds.

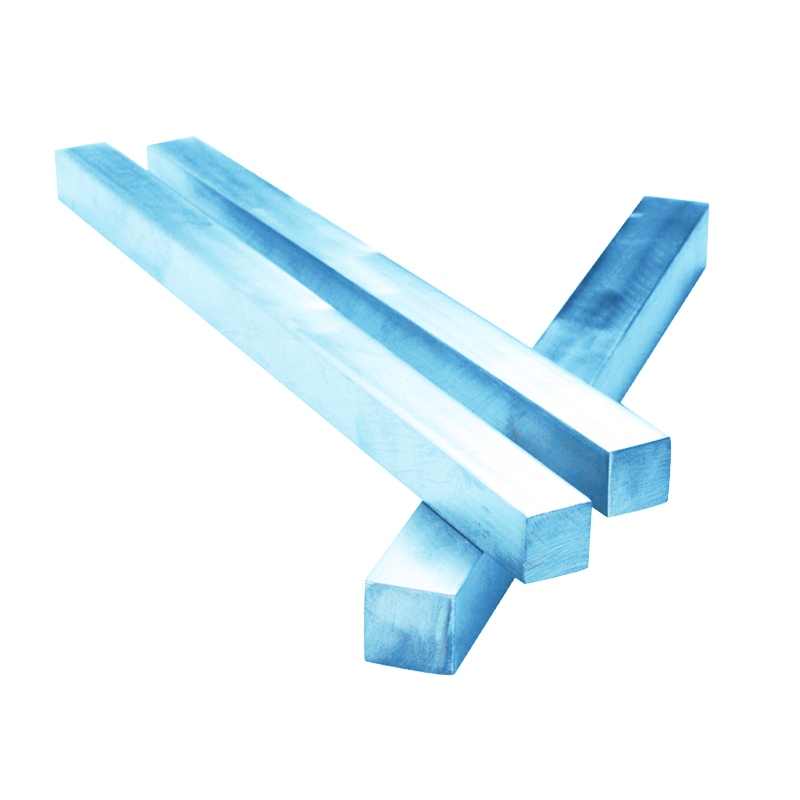

3. Parallel Sunk Key

Parallel wedges are either rectangular or square, but not tapered.

These keys are inexpensive and readily available.

keys are primarily used in the manufacturing and automotive industries due to their availability and ease of assembly.

4. Rectangular or Flat Key

These types of keys are wider than height and are sometimes called flat keys. Typically specified for 20 inch diameter shafts.

5. Square Key

A square wrench, as the name suggests, is a key with a square cross section that can be used on larger shafts.

These are typically specified for 0.25 to 1.0 inch diameter shafts, but larger square head wrenches for shafts up to 6.5 inch diameter are also available.

6. Gib Head Key

It has a head called a gib head on one end.

You can easily attach/detach the key by holding this head.

A box wrench that uses the head to reduce the impact of the hammer and prevent damage to the shank.

These keys are most commonly used to secure gears and pulleys to shafts.

7. Feather Key

Cross action of feather key is rectangular. Not tapered, but equal in length and width.

Allows relative axial movement between shaft and hub, keeping parallel sections of axle free.

These types of keys are mainly used in gears and clutches.

Benefits

- The sunken key has a higher power transmission capacity than other keys.

- The recessed key has a Phillips drive so it doesn’t slip.

Disadvantages

Sunk keys are built into both shaft and hub, resulting in higher cost.

Sunk Key Usage

Sunk keys are used for general industrial machinery. More suitable for machine tool applications.