Rock excavation methods are used to remove the rock from its place. A variety of excavation methods are used depending on the type of rock and the needs of the excavation.

We will discuss all the major rock quarrying methods.

Table of Contents

1. Drilling and Blasting:

Drilling and blasting is a commonly used method for excavating hard rock in industries like mining, quarrying, and construction. This process involves drilling holes into the rock surface and inserting explosives into them, which are then detonated to break the rock into smaller pieces.

Drilling and blasting is an efficient method for excavating hard rock, and it can be used to break down different types of rock, from soft sandstone to hard granite. However, it’s important to carefully plan and execute the process to minimize any potential environmental impacts, such as air and noise pollution.

Drilling and blasting is a useful technique for excavating hard rock, and with careful consideration of environmental factors, it can be done safely and responsibly.

2. Mechanical Excavation:

Mechanical excavation is a method of breaking and removing rock for excavation purposes using heavy machinery, including excavators, bulldozers, and rock breakers. It is often used when drilling and blasting are not suitable for the type of rock or when precision excavation is necessary.

This technique is particularly useful in areas where limited space or existing structures require careful and accurate excavation. The heavy machinery used in mechanical excavation allows for more precise control of the excavation process. Moreover, it provides a safer alternative to traditional excavation methods by keeping workers at a safe distance from the site.

Mechanical excavation is an important technique in construction and excavation projects, allowing for efficient and precise removal of rock and soil in challenging circumstances where other methods are not viable or pose safety risks.

3. Tunnel Boring:

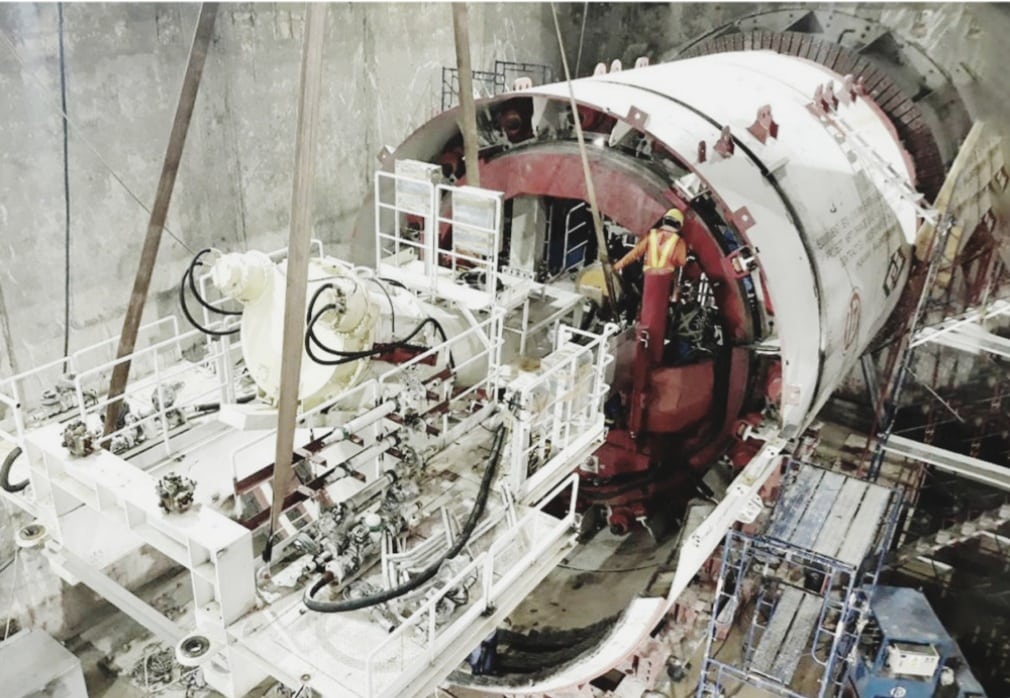

Tunnel boring is a method of excavating tunnels through solid rock, soil, or other materials. The process involves the use of a tunnel boring machine (TBM), which is a specialized piece of equipment designed to drill through the rock and create a tunnel.

A TBM consists of a rotating cutting head, which grinds away at the rock face as it moves forward. The excavated material is transported to the surface through a conveyor system, which can be as simple as a series of buckets or as complex as a fully automated conveyor belt system.

4. Chemical Excavation:

This method involves the use of chemicals to break down the rock. The chemicals are injected into the rock, and over time, they react with the minerals in the rock, causing it to weaken and break apart. This method is often used in situations where drilling and blasting are not feasible, such as in urban areas.

5. Hydro Excavation:

This method involves the use of high-pressure water to break up the rock. A water jet is directed at the rock, and the resulting slurry is then vacuumed up and removed. This method is often used in situations where precision is required and where other methods may cause damage to surrounding structures.

Sum Up

The selection of excavation method depends on a variety of factors, including the type of rock, the excavation site, and the specific requirements of the project.