Table of Contents

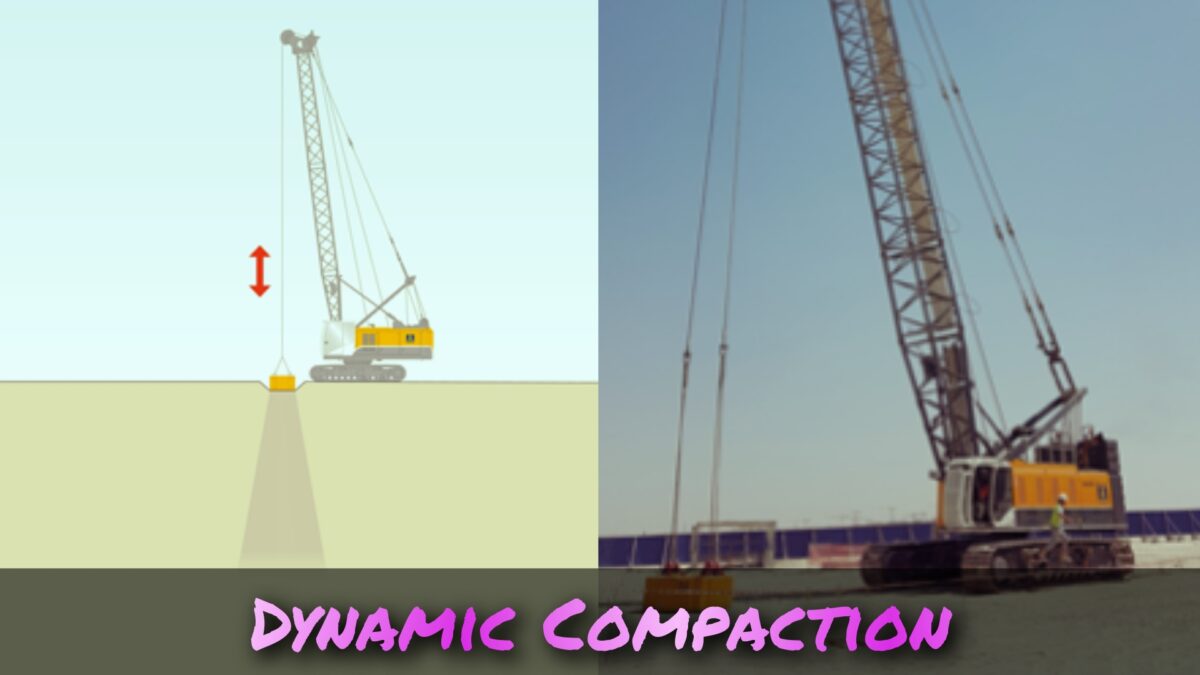

What Is Dynamic Compaction?

Dynamic compaction is a technique used to make soil denser when other methods can not be used. It involves dropping a heavy weight on the ground repeatedly to increase the soil density.

The weight used depends on how dense we want the soil to be and usually ranges from 8 to 36 tonnes. The height from which the weight is dropped can vary from 1 to 30 meters.

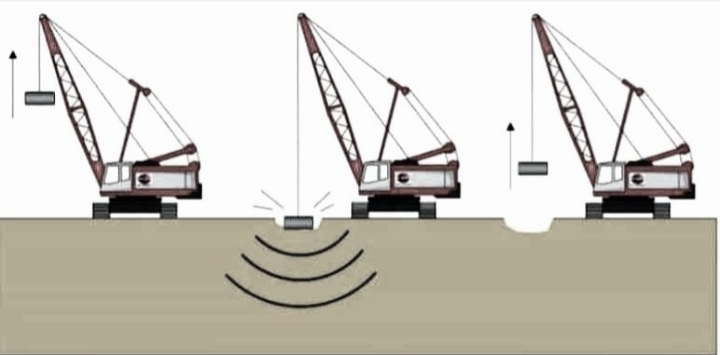

When the weight hits the ground, it creates stress waves that help to compact the soil. These waves can go down into the ground up to 10 meters. In soils without stickiness, these waves make the soil like liquid and then compact it. In sticky soils, they increase the pressure of water trapped inside the soil particles, which leads to compaction. Pore water pressure is the pressure exerted by water trapped in rocks and soils.

The level of compaction achieved depends on factors like the weight of the hammer, the height from which it is dropped, and the distance between the drop points. The first drop with the weight has the most impact and goes deeper into the ground. The following drops, when closer together, compact the shallower layers and eventually the surface.

Dynamic compaction can be used to improve the density of different types of soil, especially older fills and loose soils. But when working with soils below the water table, we need to be careful and make sure excess pore water pressure is released in a controlled manner.

Purpose Of Dynamic Compaction

The dynamic compaction technique aims to enhance the geotechnical characteristics of soil at significant depths by transmitting high-energy waves through a compressible soil layer.

Process Of Dynamic Compaction

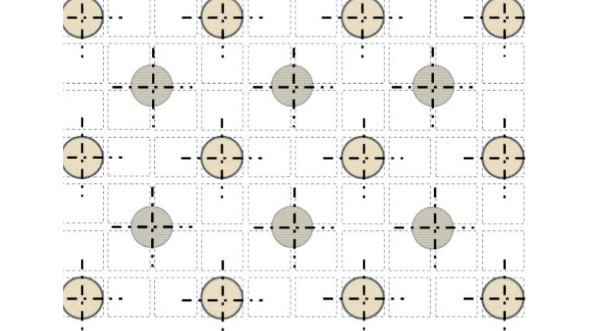

Dynamic compaction is a process used to make the ground more solid and stable. It involves lifting and dropping a heavy weight multiple times in one area. This is done in a grid pattern across the site. The spacing between the grid patterns depends on the condition of the ground below, the weight the foundation will bear, and the shape of the foundation.

When the weight is dropped, it creates a strong impact that sends shock waves through the ground. These shock waves help to fill in gaps and spaces between the soil particles, making the ground more compact and solid.

This process reduces any empty spaces in the soil, both for air and water, and makes the ground more stable.

The deeper layers of the ground are compacted with wider spacing between the weight drops, while the upper layers are compacted with closer spacing between the drops. This way, the entire ground is treated and made more solid.

Advantages Of Dynamic Compaction Technique

- It compacts the soil and makes it very strong and hard.

- It can be used on different kinds of soil, no matter how they are.

- It is a cost-effective method and saves a lot of money compared to other ways.

- It helps make construction faster by improving the soil quickly.

- It makes the soil stable and reduces the chances of the ground shaking during earthquakes.

- It makes the soil better at holding heavy buildings and structures.

- It reduces the amount of garbage that needs to be thrown away by compacting the soil.

- It keeps buildings from sinking or moving after they are built.

- It is friendly to the environment because it uses the soil we already have.

Limitations

- It cannot be used too close to buildings (30 meters) or underground pipes (15 meters) because it can cause problems.

- It doesn’t work well in areas with water less than 1.5 meters deep.

- If the top part of the soil is soft and sticky, this method may not work.

- If the soil has too much fine material (more than 20%), this method may not be effective.

- It requires doing many tests to check if the compaction worked well.

Applications And Uses

- It is used to make weak soil stronger in different places like fills, areas where mines used to be, soils that can sink easily, landfills, and places affected by sinkholes.

- It helps create new land by improving the soil in areas that were previously underwater or not useful.

- It is used to prepare the ground for big buildings like warehouses, airports, ports, roads, and train tracks, making them strong and stable.

- It is used to make the ground strong enough to hold heavy storage tanks without sinking or moving.

Faqs

Yes, dynamic compaction makes a lot of noise when the heavy weight repeatedly hits the ground. If the construction site is near residential or sensitive areas, steps should be taken to reduce the noise.

The time it takes to complete dynamic compaction depends on factors like the size of the area, desired compaction level, and soil conditions. Typically, it can take a few days to several weeks to finish, based on the project requirements.

Yes, dynamic compaction has environmental considerations. It can cause vibrations that might affect nearby structures or sensitive equipment. Environmental assessments and monitoring should be done to comply with regulations and minimize any potential environmental impacts.

Yes, dynamic compaction can be used on sloped surfaces, but additional engineering considerations are necessary. The compaction process should be carefully planned to ensure even weight distribution on the slope. Safety measures should be implemented to prevent any instability during compaction.

After dynamic compaction, it is important to conduct post-compaction testing and monitoring to evaluate its effectiveness. This may involve soil testing to measure density and stability. Depending on the project requirements, additional steps like surface leveling or further compaction techniques may be needed to achieve the desired outcome.