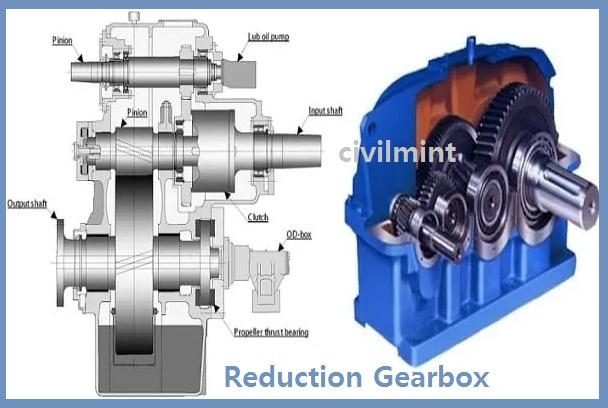

A reduction gearbox is a mechanical device used to decrease the output speed of an engine. By reducing the output speed, the output torque of the shaft is increased. The reducer converts the rotation of the output shaft of the drive motor to the speed required to drive the propeller.

This device is also called a speed reducer, reduction drive, or torque multiplier. It connects Connect the drive motor to the driven load. reducers have a simple structure like a gear train between the engine and the machine.

Reducers are most commonly used in various types of motors to improve the torque per revolution of the shaft. The gearbox of any car is a common example of a deceleration drive.

The output-to-input gear ratio slows the movement of the output shaft, increases transmission torque, and reduces shaft speed.

Some types of reducers behave like gear trains between different components, but despite their complexity, the input section has fewer teeth than the output section, allowing slow motion. This slows down the output gear and increases torque. Reduce RPM. You can also use these gears to monitor input speeds, output RPMs, and torques.

Table of Contents

Types of Reduction Gearbox

Normally, there are two types of reduction gearbox are used.

- Single Reduction Gearbox

- Double Reduction Gearbox

Let us have a look at these two types of reduction gearboxes.

1. Single Reduction Gearbox

This transmission has only one gear. There is an opening for the propeller shaft and motor shaft to enter the assembly. The small gear is a pinion driven by a drive motor shaft. When the pinion is powered by a drive motor, it continues to drive large gears. This large gear is directly coupled to the propeller shaft. When the large gear receives movement from the small gear, the propeller shaft rotates. A single gear assembly usually has twice as many gears as a pinion.

2. Double Reduction Gearbox

This type of reducer is used at very high speeds. In this gearbox, a pinion is attached to the input shaft. This pinion is connected to a central part called 1st gear. The first gear connects to another shaft with a slower pinion. The pinion gear is secured to a second reduction section that is directly connected to the drive shaft. This design helps reduce speeds up to a 20: 1 ratio.

Applications and Uses

The reducer converts the rotation of the output shaft of the main engine to the speed required to drive the propeller. There are teeth that work with the pinion and wheel to transmit movement from the driveshaft to the driven shaft, slowing it down.

I have listed various sectors where reduction gearboxes are used.

- Wind and tidal power

- Hydropower

- turbo

- Power generation

- Railroad vehicle

- cement

- Mining

- Oil and gas