A check valve is used to stop the backflow of fluid. In this type of valve, fluid can move only in one direction. A check valve is also known as a non-return valve (NRV).

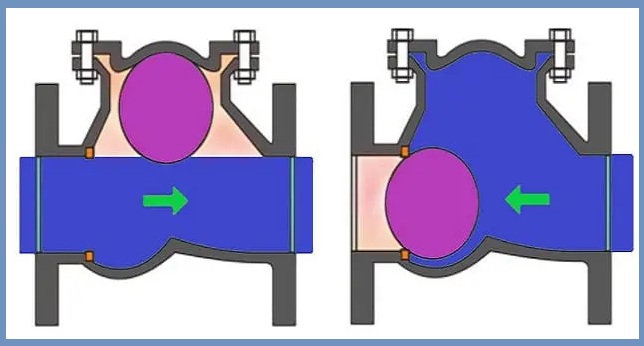

Check valves operate according to the principle of differential pressure. Simply put, it only opens if the outlet pressure is lower than the inlet pressure. When the downstream pressure is higher than the upstream pressure, the valve closes to prevent the backflow of fluid.

The concept of open pressure (pressure difference between inlet and outlet) is used to open and close a check valve or one-way valve. Therefore, the check valve has a specific open pressure and can be specified as a specific open pressure.

These valves operate automatically. Therefore, unlike other valves, no effort is required to open or close this valve. As a result, most check valves do not have a valve stem or handle. The largest valve is made of metal or plastic.

These valves are manufactured in a variety of materials, designs, and sizes. Check valves or foot valves are also very popular in home applications.

Working Concept of Check Valve

The check valve operates according to the differential pressure principle. For check valves, the minimum differential pressure upstream is called the cracking pressure.

Opening pressure plays an important role in opening and closing the check valve. This opening pressure depends on the size and design of the various check valves. When the upstream pressure equals the cracking pressure, the valve opens and fluid begins to enter the valve. When the cracking pressure is higher than the upstream pressure, the liquid will try to flow from the pressure side to the suction side. At this point, the valve closes to prevent the backflow of liquid.

The process of closing this valve depends on the size and design of the valve. Gravity or spring pressure helps to close the valve. The body of the maximum check valve is marked with an arrow that indicates the direction of fluid flow. Check valves or foot valves are typically installed in applications that have fluid backflow problems. However, these valves are highly efficient, low cost, and have excellent performance. These types of valves are a simple fix to a potential problem. Impurities in the return fluid can cause problems and contaminate upstream media. For example, sewer systems have check valves to ensure sludge and debris drainage and prevent debris from re-entering the system.

Wrapping Up

Check valves can be used as wastewater check valves or sewage check valves, chemical check valves, or water check valves, among other applications. The application determines the design and operating mode of the selected valve. Ball valves are suitable for wastewater treatment, for example, because they do not block the flow. However, the slow shutdown rate results in poor performance in chemically mixed applications.