The butterfly valve is the quarter-turn (1/4 turn) valve used to open, close, and regulate fluid flow. The operation is easy. Turn the valve handle or actuator 90 degrees to fully open and close the fluid flow.

The valve has a disc. This disc is attached to the rotating shaft. When you turn the handwheel to stop the flow of liquid, the valve disc moves down and blocks the flow. When fully open, the valve disc forms a 90-degree angle to the fluid flow.

The large butterfly valve has a gear mechanism, and the handle is connected to the valve spindle via a gear. This design makes the valve easier to operate but slows it down.

These types of valves offer high-speed operation, lightweight, simple design, small size, low cost, and low installation space. Therefore, butterfly valves are most commonly used in urban engineering, septic tanks, water pipeline construction, environmental protection, and hydropower applications. You can also operate them using automatic actuators, gears, or handles.

Table of Contents

How Does a Butterfly Valve Work?

The function of the butterfly valve is very similar to that of the ball valve. Butterfly valves are best known for being lightweight, inexpensive, easy, and quick to operate. The butterfly valve has a metal disc attached to the stem. In the flow, this disc has always been shown to increase pressure drop.

A handwheel or actuator is used to rotate this disc. The valve disc is driven by the stem to open and close the flow of fluid.

The butterfly valve works as follows:

- When the valve operator rotates the handle clockwise up to 90 degrees, the handle transfers that movement to the steam.

- When the stem receives a grip motion, the valve disc rotates.

- As the disc moves clockwise, the disc rotates and sits between the valve seats, forming an angle perpendicular to the flow.

- Therefore, the flow of liquid is completely stopped.

- When the operator wants to fully open the valve, rotate the handle counterclockwise up to 90 degrees.

- When the disc is moved counterclockwise by the handle, the disc separates from the valve seat and forms an angle parallel to the fluid flow, allowing the fluid to flow.

- The operator rotates the disc to make the throttle flow partially open and closed.

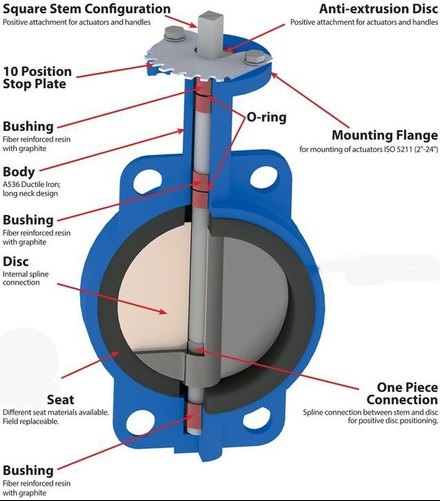

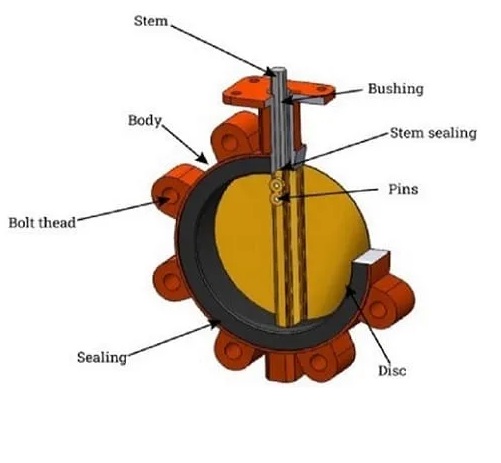

Design/Construction of Butterfly Valve

The butterfly valve comprises the following parts:

- Stem

- Handwheel

- Disk

- Seat

- Body

- Bolt thread

- Pins

- Stem sealing

- Bushing

Pros

- They are smaller in size and lighter in weight than globe valves and ball valves.

- This type of valve has a low cost compared to ball valves.

- Butterfly valves require a small installation area.

- They have an easy and quick operation.

- These valves are used to open, close or regulate fluid flow.

- The disc valve has a low weight compared to the ball valve.

- These valves require very little maintenance.

- They are very precise as they are used in different industries.

- They have high-pressure recovery and low-pressure loss.

- The butterfly valve has a compact design.

- It requires much less support structure than ball valves of the same diameter.

- A particular part of the disc always faces flow even when it is fully open.

- Therefore, regardless of the setting, butterfly valve operation always changes the valve’s pressure.

Cons

- Butterfly valves cannot provide the same excellent sealing performance as ball valves.

- The use of butterfly valve throttling is limited to low-pressure relief systems.

- The disc is always present in the line even when fully open; Therefore, it increases and decreases the pressure.

- The movement of the valve disc is guided and influenced by turbulence.

Uses/Applications

- Urban engineering

- Construction of water pipes

- Environmental protection

- Hydroelectric applications

- Chemical and food industry

- Wastewater

- Pure water