Table of Contents

Introduction:

A booster pump is a form of centrifugal pump as it makes use of centrifugal pressure. In this type of pump, one or more impellers are added to pump the fluid. A booster pump is a mechanical tool that is used to enhance the pressure of the water or different fluids. The improved pump is likewise referred to as a pressure pump.

Installing the booster pump will add extra pressure to the water and return the pressure to the desired level. In this way, water can easily reach the required height of a building.

A hydraulic pump increases sufficient pressure on the water and raises the pressure to send the water to the desired location. Water pressure is the force that moves water from a water source to a desired water supply location or system. The water carried from the water source to the house is under high pressure. When water flows from the tank to the desired area, friction and other losses in the pipeline can cause energy losses. This energy loss prevents water from reaching the upper floors of skyscrapers.

Gas booster pumps work like gas compressors. However, it is a simpler machine, usually with a single step of compression, used to increase gas pressure that is already above atmospheric pressure. Booster pumps work in conjunction with other pump combinations. In other words, booster pumps alone cannot pump liquids to the desired area or location. The main purpose of these pumps is to “simply increase” the operation of existing pump systems.

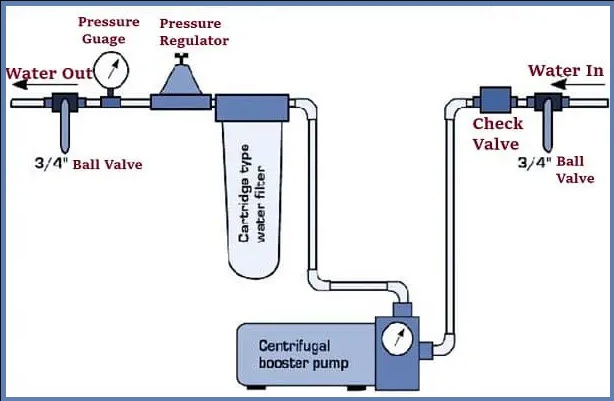

If the water supply pressure is not sufficient to meet the pressure and flow rate required for the plumbing system, a water supply booster pump should be installed. Because it increases the pressure and flow rate of water. These pumps can be used for both gases and liquids, but the design may vary depending on the type of liquid.

The booster can be used to carry high-pressure gas, fill cylinders, increase gas pressure, and remove gas. Booster pumps are widely used in water systems and have low waste pollution features.

Booster pumps are used in many military, municipal, and commercial applications. These types of pumps are also used in various industries such as food processing, mining, and aerospace.

Working Concept of Booster Pump

A booster pump works like a fan. The purpose of the booster pump is to increase the pressure of the liquid and, in some cases, to increase the flow rate. This pump works with existing pumps. The booster pump operates with the help of a built-in expansion tank. A closed tank with an airbag. The principle of operation of the pump is to fill the tank that flows with the airbag with water. This compresses the air in the airbag and the water increases the pressure.

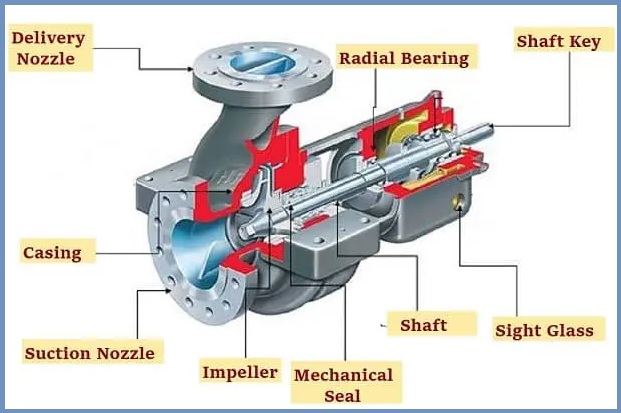

Most of the booster pumps in the market are centrifugal pumps. This means that this pump has one or more impellers for compressing the liquid.

The water pressure pump working concept is as follows.

- When operating a hydraulic booster pump, water is introduced into the pump from the water source.

- When the water hits the impeller blade, the blade adds kinetic energy to the water and increases its speed.

- The water then enters the swirl or diffuser.

- The diffuser or volute converts the velocity of water into pressure.

- This raises the pressure of the water and reaches the desired height.

Types of Booster Pump

Single-stage Pumps & Multistage Pumps are two types of booster pumps.

1. Single-stage Pump

As the name of this pump suggests, it increases the pressure of water or other liquids in just one step. Single-stage pumps use only one impeller to increase the pressure of the liquid. It is less efficient than a multi-stage pump but requires less space for installation.

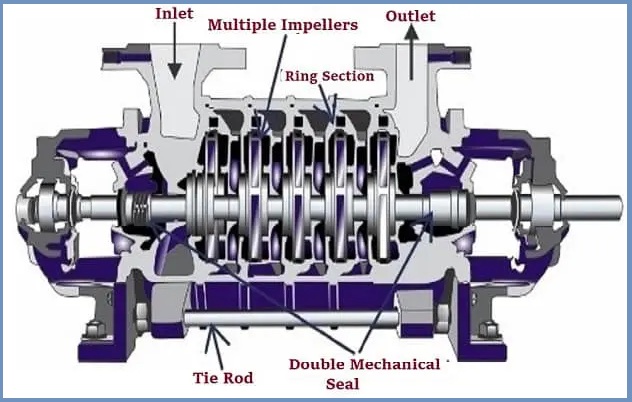

2. Multistage Pump

This pump uses multiple stages to pressurize the fluid. In this pump, each stage has an impeller. Use multiple impellers for the liquid.

Some Useful Applications of Booster Pump

This type of pump is used in the following industrial sectors.

- Steel Industry

- A metal industry like Non-ferrous

- Mining

- Automotive

- Cleaning and Abrasive Liquids